Carbon fiber reinforced polyphenylene sulfide composite material and preparation method thereof

A composite material and polyphenylene sulfide technology, which is applied in the field of carbon fiber composite materials to achieve the effects of good toughness, improved toughness and heat resistance, and high heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

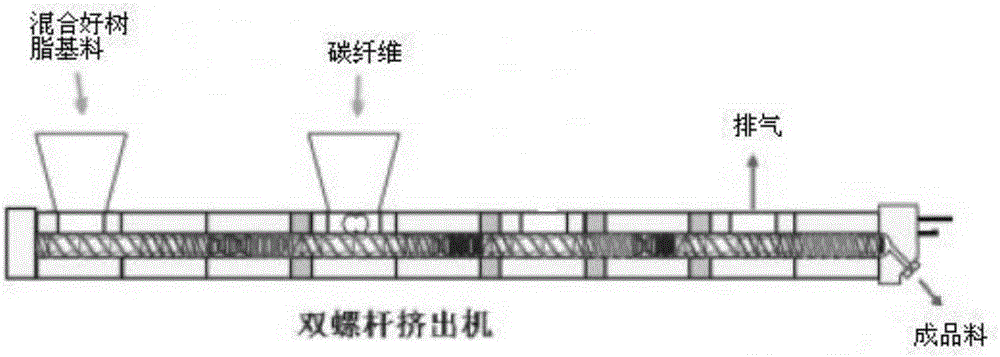

[0053] Correspondingly, the present invention also provides a method for preparing the above-mentioned carbon fiber reinforced polyphenylene sulfide composite material, including:

[0054] After mixing polyphenylene sulfide, carbon fiber, soluble polytetrafluoroethylene, polysiloxane and an antioxidant, melt kneading is carried out to obtain a carbon fiber reinforced polyphenylene sulfide composite material.

[0055] In the embodiment of the present invention, it is preferred to mix polyphenylene sulfide, soluble polytetrafluoroethylene, polysiloxane and antioxidant to obtain a mixed resin base material; then mix carbon fibers with the mixed resin base material for melt kneading, A carbon fiber reinforced polyphenylene sulfide composite material is obtained.

[0056] In the present invention, the content of each material is as described above, and will not be repeated here. The equipment used to prepare the composite material in the present invention is conventional equipment...

Embodiment 1

[0065] (1) Treatment of carbon fiber: at room temperature, put 25kg of carbon fiber (500g per roll, a total of 50 rolls) into a 600L prepared treatment solution (the concentration of the treatment agent is 2.0mL / L, The treatment liquid comprises water, silane coupling agent (KH560 provided by Sichuan Chenguang Chemical Co., Ltd.), potassium titanate coupling agent, ammonium cerium nitrate and ethanol) in the treatment tank, and placed for 8 minutes for treatment; after treatment, take it out and let it dry, and then The treated carbon fibers were dried at 110° C. to obtain modified carbon fibers after 24 hours.

[0066] (2), 58% of polyphenylene sulfide, 8% of soluble polytetrafluoroethylene, 2% of polysiloxane, 1% of antioxidant 1010 and 1% of silicone powder are mixed evenly to obtain mixed resin base;

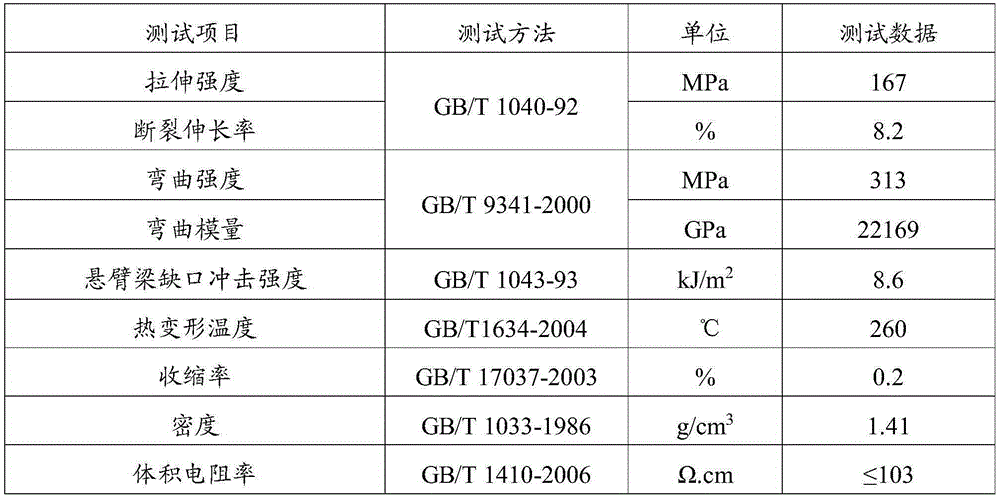

[0067] (3), add 30% of the carbon fiber treated in step (1) and the mixed resin base material obtained in step (3) into a twin-screw extruder, and melt and shear it at a te...

Embodiment 2

[0073] (1) Treatment of carbon fiber: at room temperature, put 25kg of carbon fiber (500g per roll, a total of 50 rolls) into a 600L prepared treatment solution (the concentration of the treatment agent is 2.0mL / L, Treatment liquid comprises water, silane coupling agent (same as embodiment 1), potassium titanate coupling agent, ammonium cerium nitrate and ethanol) in the treatment tank, place 5 minutes to process; The carbon fiber was dried at 100°C, and the modified carbon fiber was obtained after 26 hours.

[0074] (2), 53.7% of polyphenylene sulfide, 7% of soluble polytetrafluoroethylene, 2% of polysiloxane, 1.3% of antioxidant 168 and 1% of silicone powder are mixed evenly to obtain mixed resin base;

[0075] (3), add 35% of the carbon fiber treated in step (1) and the mixed resin base material obtained in step (3) into a twin-screw extruder, and melt and shear it at a temperature of 250°C to 300°C through the twin-screw extruder Cutting, kneading, extruding and granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com