Polyethylene base film, lithium battery diaphragm slurry and lithium battery diaphragm prepared from polyvinyl base film and lithium battery diaphragm slurry

A technology of polyethylene-based film and lithium battery diaphragm, which is applied in the direction of lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem of low mechanical strength, and achieve the goal of improving heat resistance, toughness and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of polyvinyl film, comprising the following steps:

[0043] Step 1: 25 parts by mass of ultra-high molecular weight polyethylene with a weight average molecular weight of 1 million, 5 parts by mass of glass fiber, 1 part by mass of silane coupling agent, 68 parts by mass of paraffin oil and 2,6-di-tert-butyl-4 - 1 mass part of methyl phenol is heated and stirred to obtain a mixture, the mixing temperature of the mixing tank is 80° C., and then heated and blended by a twin-screw extruder to form a homogeneous blend. The screw speed of the twin-screw extruder is 40 rpm , the extrusion temperature is 180°C. ;

[0044] Step 2: cooling and shaping the homogeneous blend described in step 1 through a casting process to obtain a cast sheet;

[0045] Among them, the obtained high-temperature homogeneous blend is accurately metered by the melt pump and then sent into the die head, and the high-temperature molten body sent into the die head flows out from th...

Embodiment 2

[0055]A lithium battery separator slurry, its raw material formula includes 35 parts by mass of aluminum oxide, polystyrene-butadiene emulsion (Nuo Na Chemical Technology Co., Ltd., model: 9003-55-8 (CAS No.)) 5 parts by mass, 0.08 parts by mass of sodium lauryl sulfate, 0.6 parts by mass of sodium polyacrylate, 8 parts by mass of sodium carboxymethylcellulose, 2 parts by mass of auxiliary agent and 60 parts by mass of deionized water; A blend formed by mixing polyamide and hydrogenated styrene-butadiene-styrene triblock copolymer (SEBS-g-MA), in which polyamide and hydrogenated styrene-butadiene- The mass ratio of the styrene triblock copolymer is 96:4.

[0056] The preparation method of the above-mentioned lithium battery diaphragm slurry comprises the following steps:

[0057] Step 1: Add sodium polyacrylate to deionized water, and disperse for 20 minutes at a speed of 1000r / min to obtain a mixed solution;

[0058] Step 2: adding aluminum oxide and additives to the obtain...

Embodiment 3

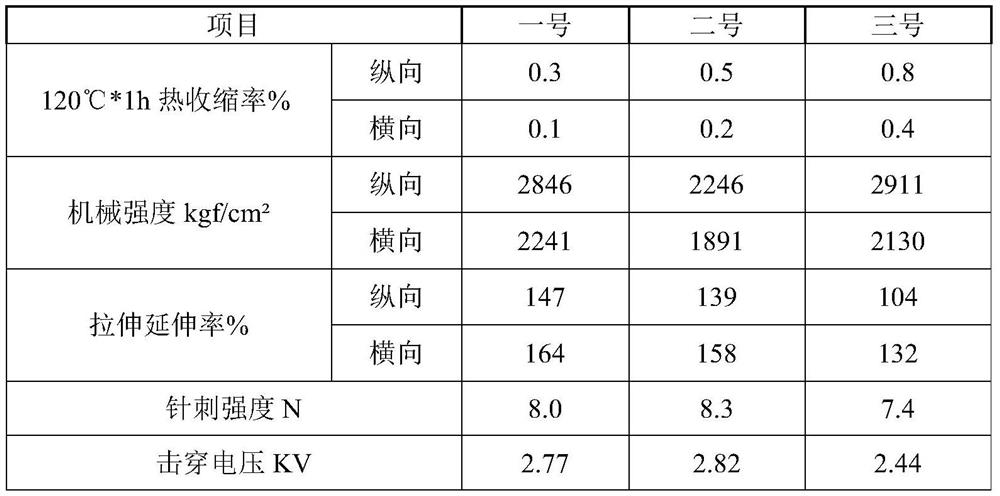

[0064] No. 1 lithium battery separator, including the polyethylene base film prepared in Example 1 and the coating formed by the lithium battery separator slurry prepared in Example 2 coated on one side of the polyethylene base film. The thickness of the polyethylene base film is 12 μm, and the coating thickness is 4 μm.

[0065] No. 2 lithium battery separator, including the polyethylene-based film prepared in Comparative Example 1 and the coating formed by the lithium battery separator slurry prepared in Example 2 coated on one side of the polyethylene-based film. The thickness of the polyethylene base film is 12 μm, and the coating thickness is 4 μm.

[0066] No. 3 lithium battery separator, including the polyethylene-based film prepared in Example 1 and the coating formed by the lithium battery separator slurry prepared in Comparative Example 2 coated on one side of the polyethylene-based film. The thickness of the polyethylene base film is 12 μm, and the coating thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com