High-CTI-value and high-heat-resistance polycarbonate composition and preparation method thereof

A polycarbonate, high heat-resistant technology, applied in the field of engineering plastics, can solve the problems affecting the impact strength and heat resistance of PC resin, the limitation of thin-walled flame retardancy of PC resin, and the failure of PC original resin to meet safety standards. The effect of improving tracking resistance, improving heat resistance, and improving heat resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

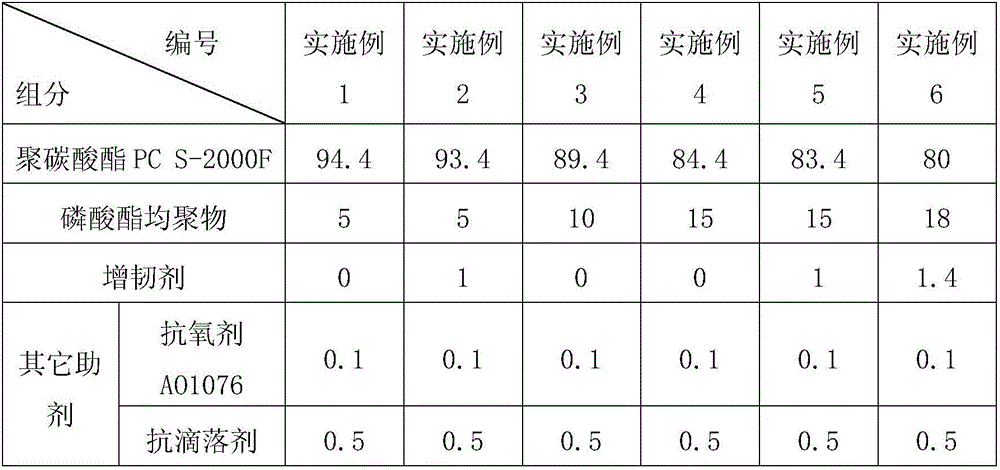

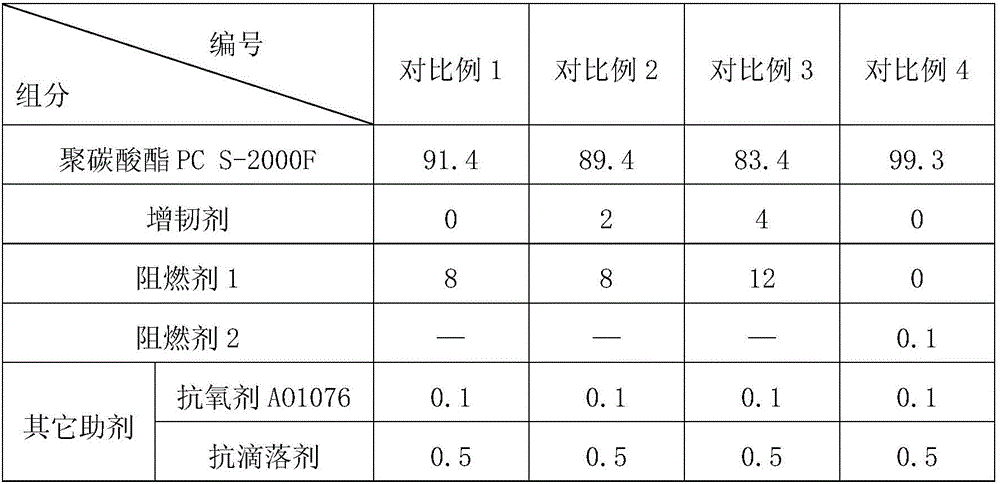

[0015] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0016] As we all know, material selection, raw material formula, and preparation process are the three major factors that determine product quality, and the three influence each other. Therefore, in order to better illustrate the advantages and innovations of the high CTI value and high heat resistance polycarbonate composition product of the present invention, the material selection of the high CTI value and high heat resistance polycarbonate composition product of the present invention will be used below Materials, raw material formulations and preparation methods are described in detail.

[0017] (1) material selection situation of the present invention:

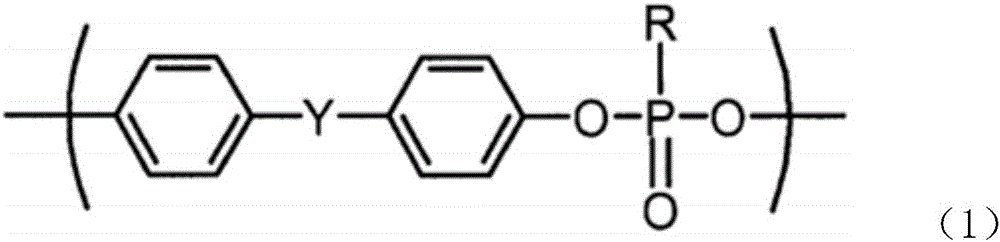

[0018] The invention discloses a polycarbonate composition with high CTI value and high heat resistance. The raw materials used mainly include polycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com