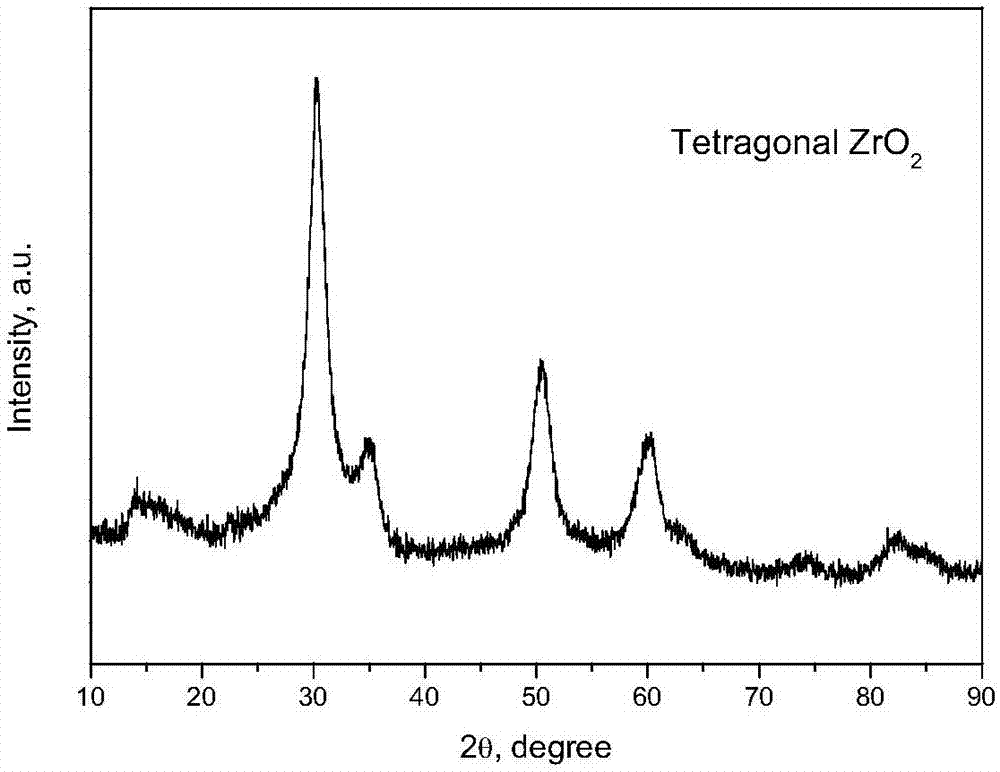

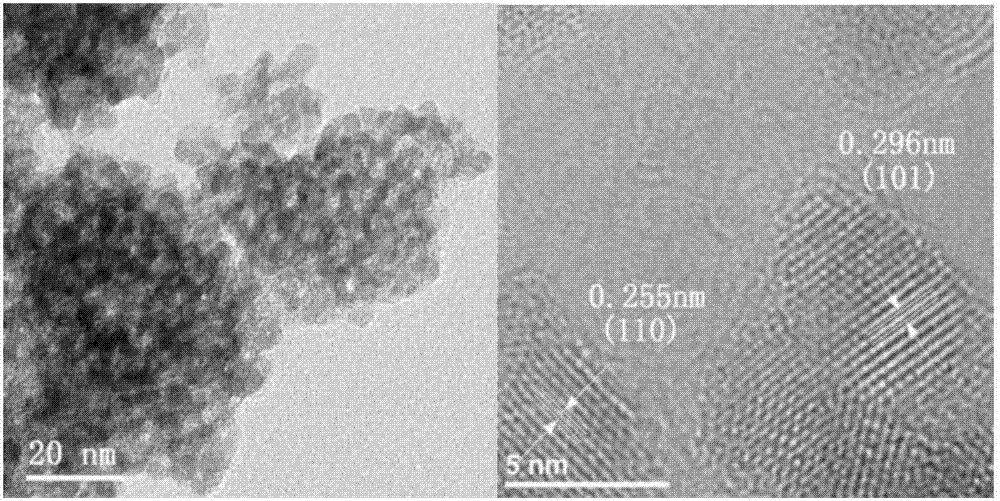

Tetragonal nano zirconia with high specific surface and high purity, preparation method of nano zirconia as well as application in catalytic conversion of catalytic synthesis gas

A technology of nano-zirconia and tetragonal phase, which is applied in the direction of nanotechnology, zirconia, chemical instruments and methods for materials and surface science, and can solve the problems of crystal phase impurity, small specific surface area, and tetragonal phase zirconia production scale Minor problems, to achieve the effects of not easy sintering, low boiling point, low equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

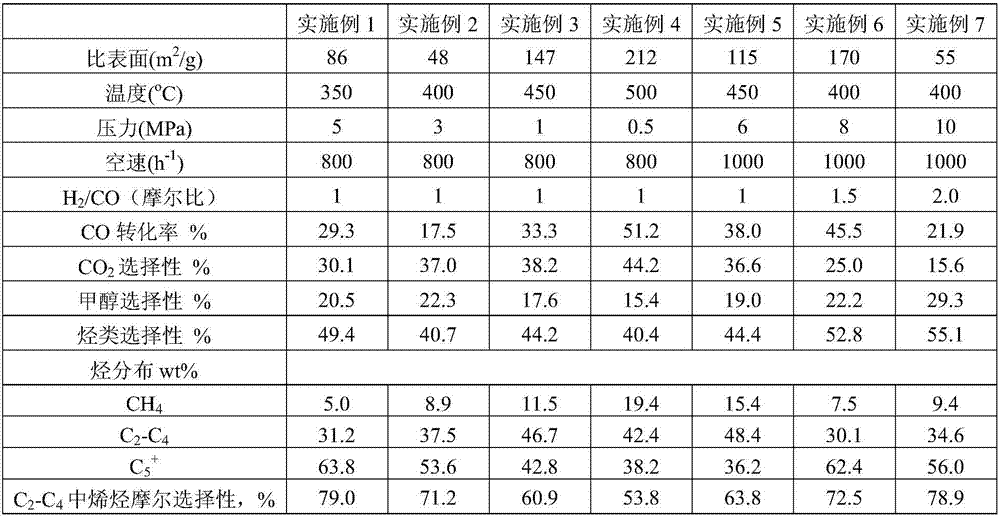

Examples

Embodiment 1

[0050] Example 1. Preparation of tetragonal phase nano-zirconia powder with high specific surface area and high purity

[0051] 1) Weigh 9.25 g of hydrated zirconyl nitrate and add it into 60 mL of deionized water, stir at 70° C. for 15 min to prepare an aqueous zirconium salt solution with a molar concentration of 0.571 mol / L.

[0052] 2) Take the aqueous zirconium salt solution obtained above, add 80 mL of ethanol and 140 mL of n-hexane in sequence, and stir thoroughly.

[0053] 3) Under the condition of continuous stirring, add 24.36g of sodium oleate, the molar ratio of sodium oleate to zirconyl nitrate (calculated as zirconium atoms) is 2:1, heat to 70°C and boil and reflux, then stir and reflux at 70°C for 4h.

[0054] 4) The obtained reaction mixture was layered while hot, and the supernatant was taken, washed 5 times with 30 mL of deionized water until the upper solution was light yellow and clear, and dried in an oven at 120° C. to obtain a yellow colloidal zirconyl o...

Embodiment 2

[0059] Example 2. Preparation of high specific surface and high purity tetragonal phase nano zirconia powder

[0060] 1) Weigh 9.26 g of hydrated zirconyl nitrate and add it into 60 mL of deionized water, stir at 60° C. for 10 min to prepare an aqueous solution with a molar concentration of 0.571 mol / L.

[0061] 2) Take the aqueous zirconium salt solution obtained above, add 90 mL of ethanol and 130 mL of n-hexane in sequence, and stir thoroughly.

[0062] 3) Under the condition of continuous stirring, add 49g of sodium oleate, the molar ratio of sodium oleate to zirconium oxynitrate (calculated as zirconium atoms) is 4:1, heat to 58°C to boil and reflux, then stir and reflux at 58°C for 24h.

[0063] 4) The obtained reaction mixture was separated into layers while it was hot, and the supernatant was taken, washed 5 times with 30 mL of deionized water until the upper solution was light yellow and clear, and evaporated at 90° C. to obtain zirconyl oleate in yellow colloidal for...

Embodiment 3

[0067] Example 3. Preparation of high specific surface and high purity tetragonal phase nano zirconia powder

[0068] 1) Weigh 18.52 g of zirconyl nitrate and add it into 120 mL of deionized water, stir at 60° C. for 10 min to prepare an aqueous solution with a molar concentration of 0.55 mol / L.

[0069] 2) Take the aqueous zirconium salt solution obtained above, add 160 mL of ethanol and 280 mL of n-hexane in sequence, and stir thoroughly.

[0070] 3) Under the condition of continuous stirring, add 49g of sodium oleate, the molar ratio of sodium oleate to zirconium oxynitrate (calculated as zirconium atoms) is 2:1, heat to 70°C to boil and reflux, then stir and reflux at 70°C for 12h.

[0071] 4) The obtained reaction mixture was separated into layers while it was hot, and the supernatant was taken, washed 5 times with 30 mL of deionized water until the upper solution was light yellow and clear, and evaporated at 90° C. to obtain zirconyl oleate in yellow colloidal form.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com