Method for preparing titanium silicon molecular sieve TS-1 with high framework titanium content

A technology of titanium-silicon molecular sieve and skeleton titanium, which is applied in the direction of molecular sieve compounds, molecular sieve characteristic silicates, molecular sieves and alkali exchange compounds, etc., can solve the problems of unavoidable non-skeleton titanium and low skeleton titanium content, so as to reduce cost input, Reduced synthesis cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 20.3g of methyl orthosilicate into a jacketed three-necked flask, sequentially add 0.78g of tetraethyl titanate and 42.1g of 25wt% tetrapropylammonium hydroxide solution, immerse the three-necked flask in a 40°C water bath, and hydrolyze for 1.5 h. The hydrolyzate was dealcoholized at 90°C for 1 hour, 180mL of starch solution with a concentration of 5wt% was added, stirred evenly, the mixed solution was put into a crystallization kettle, and crystallized at 160°C for 48h, the crystallized product was washed and dried, Calcined at 540°C for 6 hours to obtain TS-1, which is numbered TS-1-E.

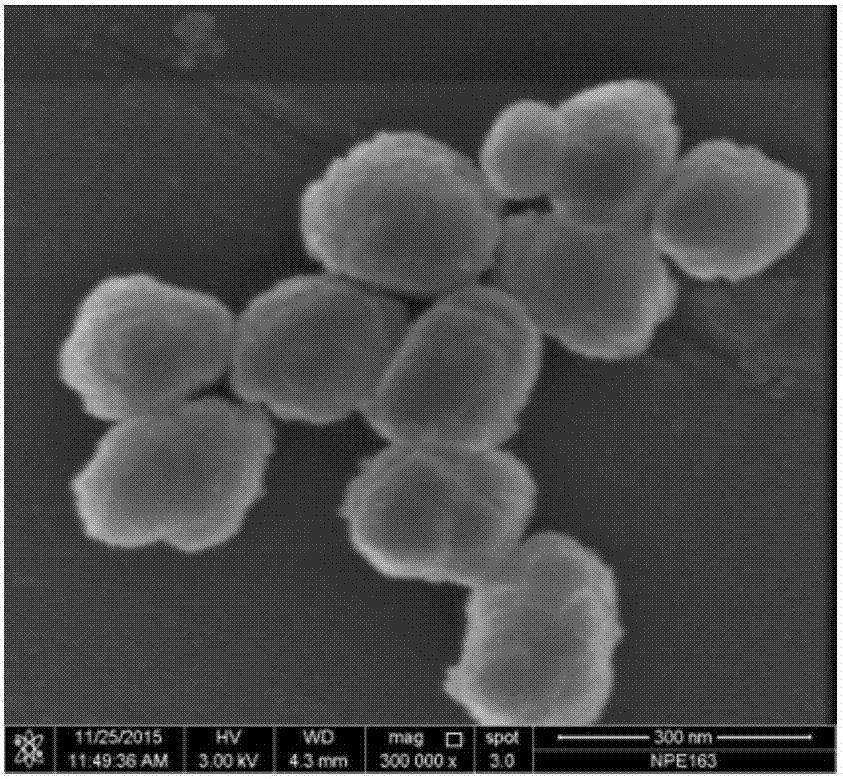

[0051] image 3 It is the scanning electron micrograph of the titanium-silicon molecular sieve TS-1-E that embodiment 1 makes, as can be seen from the figure, the morphology of the sample that the present embodiment makes and figure 1 Very similar, ellipsoidal, particle size is about 200nm.

[0052] Depend on Figure 5 It can be seen that the sample TS-1-E synthesized accordi...

Embodiment 2

[0055] Add 29.6g of ethyl orthosilicate into a jacketed three-necked flask, sequentially add 1.60g of tetrabutyl titanate and 33.6g of 25wt% tetrapropylammonium hydroxide solution, immerse the three-necked flask in a 50°C water bath, and hydrolyze for 3 hours . The hydrolyzate was dealcoholized at 90°C for 1 hour, 100mL of starch solution with a concentration of 5wt% was added, stirred evenly, the mixed solution was put into a crystallization kettle, and crystallized at 170°C for 60h, the crystallized product was washed and dried, Calcined at 540°C for 5 hours to obtain TS-1, which is numbered TS-1-F.

[0056] Figure 4 It is the scanning electron micrograph of the titanium-silicon molecular sieve TS-1-F that embodiment 2 makes, as can be seen from the figure, the morphology of the sample that the present embodiment makes and figure 1 Very similar, ellipsoidal, particle size is about 200nm.

[0057] Depend on Figure 5 It can be seen that the sample TS-1-F synthesized acco...

Embodiment 3

[0060] Add 20.8 g of ethyl orthosilicate into a jacketed three-necked flask, sequentially add 0.96 g of tetrabutyl titanate and 9.8 g of 40 wt % tetraethylammonium hydroxide solution, immerse the three-necked flask in a 50° C. water bath, and hydrolyze for 1 h. The hydrolyzate was dealcoholized at 90°C for 0.5h, and 90mL of starch solution with a concentration of 8wt% was added, stirred evenly, and the mixed solution was put into a crystallization kettle, and crystallized at 150°C for 72h, and the crystallized product was washed and dried. Calcined at 540°C for 3 hours to obtain TS-1, which is numbered TS-1-G.

[0061] Depend on Figure 5 It can be seen that the sample TS-1-G synthesized according to Example 3 only contains framework titanium, and does not contain hexacoordinated non-framework titanium and anatase TiO 2 .

[0062] Depend on Image 6 It can be seen that the TS-1-G synthesized according to Example 1 also has a typical MFI structure, and the crystallinity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com