Planetary gear transmission with automatic gear shifting and hoist installed with the transmission

A planetary gear and automatic gear shifting technology, which is applied in the direction of gear transmission, hoisting device, transmission device, etc., can solve the limitation of speed regulation range and light load energy saving, high frequency output does not save power, and the tower crane has a large lifting stroke, etc. problems, to achieve remarkable energy-saving effects, energy-saving speed-up effects, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

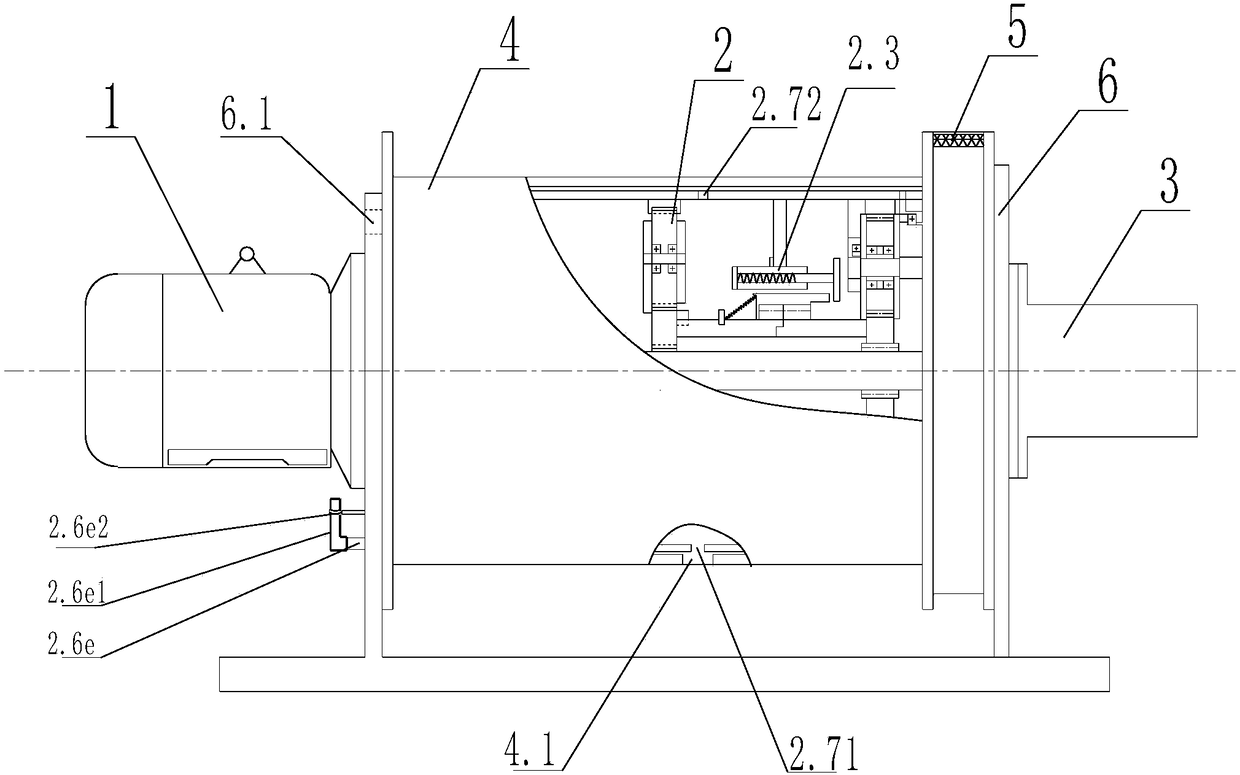

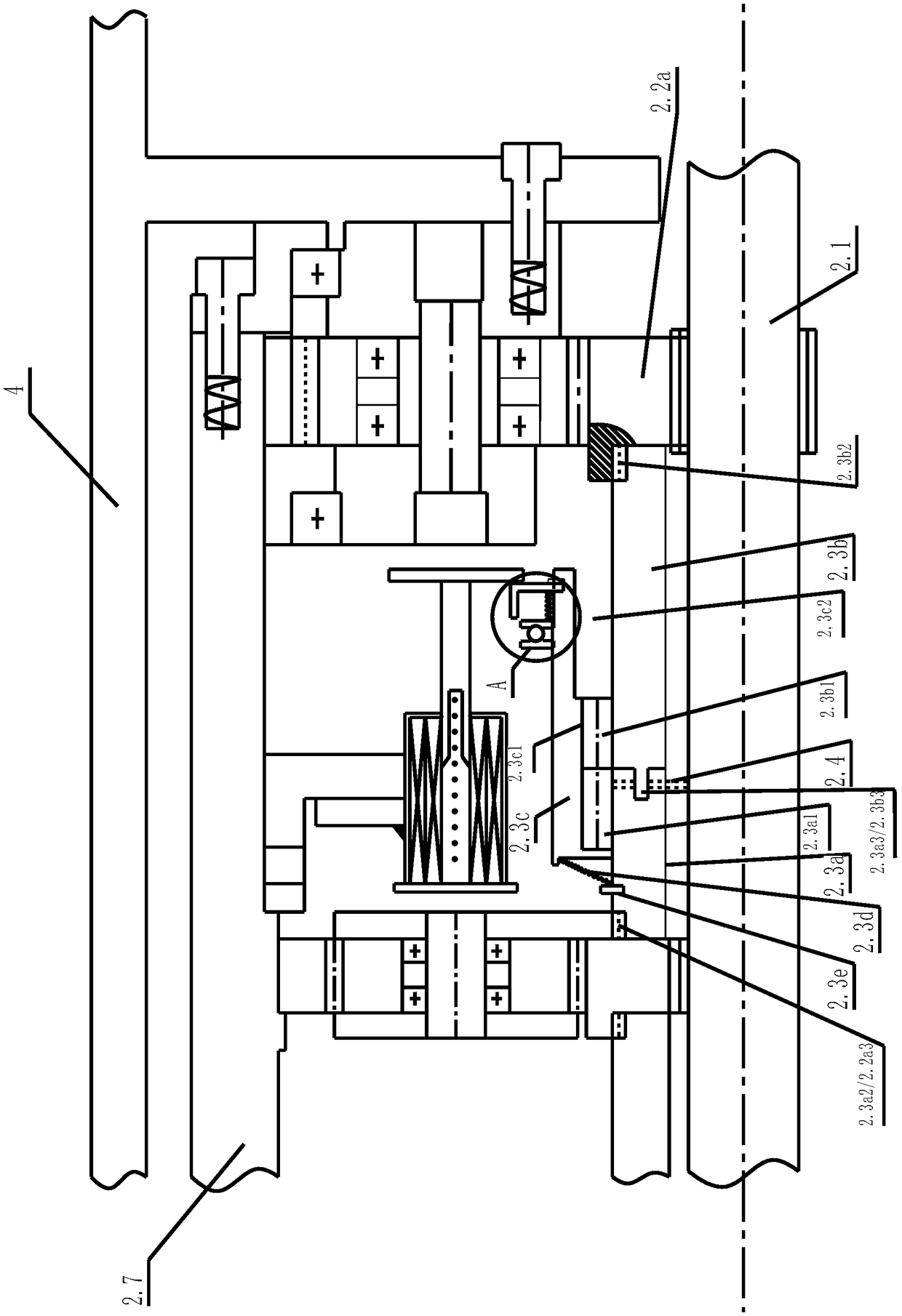

[0036] figure 1 , figure 2 The planetary gear electric winch with automatic gear shifting, the flange plate of the motor 1 is fixed on one end of the frame 6 with bolts, the transmission 2 is installed inside the reel 4, and one end of the shell 2.7 is fixed on the frame 6. The gear center sun gear 2.2a is centered with the same internal spline 2.2a1, the clutch 2.3 is set between the planetary gears, the last n-stage planetary gear frame is connected with the reel 4, and the shift mechanism 3 is installed at the other end of the frame; the motor is hollow The rotor shaft 1.1 is provided with a full-length internal spline 1.1a, and the power input external spline 2.1a at the end of the driving shaft 2.1 meshes with the internal spline 1.1a; the driving shaft 2.1 runs through the transmission 2, and one end is inserted into the motor rotor shaft 1.1, and the other One end is inserted into the shifting mechanism 3, and driven by the shifting mechanism 3, the external splines 2...

Embodiment 2

[0047] like Figure 4 For the transmission with large transmission ratio shown, the first stage adopts K-H-V small tooth difference or cycloidal pin gear reducer as the high-speed stage, and the low-speed stage adopts one-stage or multi-stage 2K-H planetary gear reduction mechanism, and clutches are set between planetary gears at all stages 2.3, take the design eccentricity e measured radially from the center of the eccentric wheel 2.6 of the boom arm as the center, set the inner spline 2.2a1 in the opening; set the hollow journal 2.6a concentric with the inner spline 2.2a1 at both ends of the eccentric wheel, and the hollow journal One end of 2.6a is installed in the center bearing 2.6c of the end cover 2.6b, and the other end is installed in the center bearing 2.6c of the power output disk 2.6d; the hollow shaft 2.6d1 integrated with the power output disk 2.6d is divided by two diameters. The bearing 2.6c is installed in the other end cover 2.6b1, and the inner diameter of t...

Embodiment 3

[0052] said Image 6 The normally open clutch between the first and second gears shown is suitable for light and medium load equipment such as automobile cranes and tower cranes. The clutch tubular part 2.3c is pushed by the inner spring 2.3d1, and its end is arranged on the tubular The elastic retaining ring 2.3e on part 2.3a is in contact, the inner spline 2.3c1 is only engaged with the outer spline 2.3a1, the outer spline 2.3b1 is located at the position of the toothless empty ring 2.3c2, the clutch is normally open; The spline 2.1b meshes with the internal spline 2.2a1 of the first-speed planetary gear, the tubular member 2.3c moves to the power output side under the drive of the electromagnetic switch or hydraulic cylinder, and the internal spline 2.3c1 and the external spline 2.3b1 engage the clutch; transform After the gear position, the tubular member 2.3c loses power and returns under the action of the compression spring 2.3d, and the clutch is separated into a normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com