High-strength light hollow brick and preparation process thereof

A hollow brick and high-strength technology, applied in the field of hollow bricks, can solve problems such as poor shock resistance, high energy consumption, and increased production costs, and achieve the effects of reducing production costs, simplifying the preparation process, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

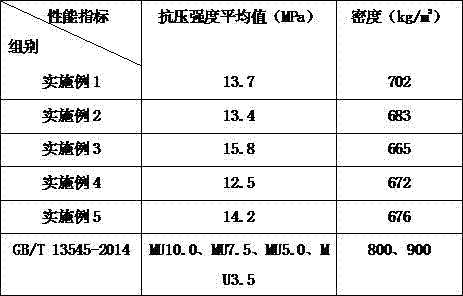

Examples

Embodiment 1

[0023] A high-strength lightweight hollow brick, including the following raw materials: 70kg of dehydrated river mud, 50kg of blast furnace slag, 30kg of kaolin, 10kg of expanded perlite, 5kg of vitrified microbeads, 5kg of purple sand shale, 5kg of ceramic fiber, 5kg of shell carbon powder, formic acid Calcium 4kg, hydroxyethyl methylcellulose 4kg, methyl methacrylate 3kg and cement-based osmotic crystalline waterproofing agent 5kg.

[0024] Among them, the water content of the dehydrated river mud is controlled at 15%, and the blast furnace slag, expanded perlite and purple sand shale are crushed to a particle size of 1-2mm by a jaw crusher. The shell charcoal powder is only coconut shell charcoal, and the hollow brick is set The porosity rate is 40%, and the hole type is a rectangular hole.

[0025] The preparation process of the above-mentioned high-strength lightweight hollow brick is carried out according to the following steps:

[0026] 1) Weigh the above raw materials...

Embodiment 2

[0031] A high-strength lightweight hollow brick, including the following raw materials: 80kg of dehydrated river mud, 60kg of blast furnace slag, 40kg of kaolin, 15kg of expanded perlite, 10kg of vitrified microbeads, 10kg of purple sand shale, 8kg of ceramic fiber, 8kg of shell carbon powder, formic acid Calcium 6kg, hydroxyethyl methylcellulose 5kg, methyl methacrylate 4kg, cement-based osmotic crystalline waterproofing agent 8kg.

[0032] Among them, the water content of the dehydrated river mud is controlled at 18%, and the blast furnace slag, expanded perlite and purple sand shale are crushed to a particle size of 1-2mm by a jaw crusher, and the shell carbon powder is equal to rice husk powder and straw powder The mixture, and the porosity of the hollow brick is set to 40%, and the hole type is a rectangular hole.

[0033] The preparation process of the above-mentioned high-strength lightweight hollow brick is carried out according to the following steps:

[0034] 1) Wei...

Embodiment 3

[0039] A high-strength lightweight hollow brick, including the following raw materials: 100kg of dehydrated river mud, 80kg of blast furnace slag, 50kg of kaolin, 20kg of expanded perlite, 15kg of vitrified microbeads, 15kg of purple sand shale, 10kg of ceramic fiber, 10kg of shell carbon powder, formic acid Calcium 8kg, hydroxyethyl methylcellulose 6kg, methyl methacrylate 5kg, cement-based osmotic crystalline waterproofing agent 10kg.

[0040] Among them, the water content of the dehydrated river mud is controlled at 15%, and the blast furnace slag, expanded perlite and purple sand shale are crushed to a particle size of 1-2mm by a jaw crusher. The shell charcoal powder uses coconut shell charcoal, rice husk powder and straw powder The mixture of the three is equal, and the porosity of the hollow brick is set to 40%, and the hole type is a rectangular hole.

[0041] The preparation process of the above-mentioned high-strength lightweight hollow brick is carried out according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com