Early-strength low-shrinkage prestressed tunnel pressure slurry and preparation method thereof

A technology of channel grouting and low shrinkage, which is applied in the field of building materials, can solve the problems of poor fluidity and stability of fresh grout, insufficient cohesion, and insufficient density of slurry, etc., achieve good viscosification effect, and solve shrinkage condition and early crack problems, good water storage - effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

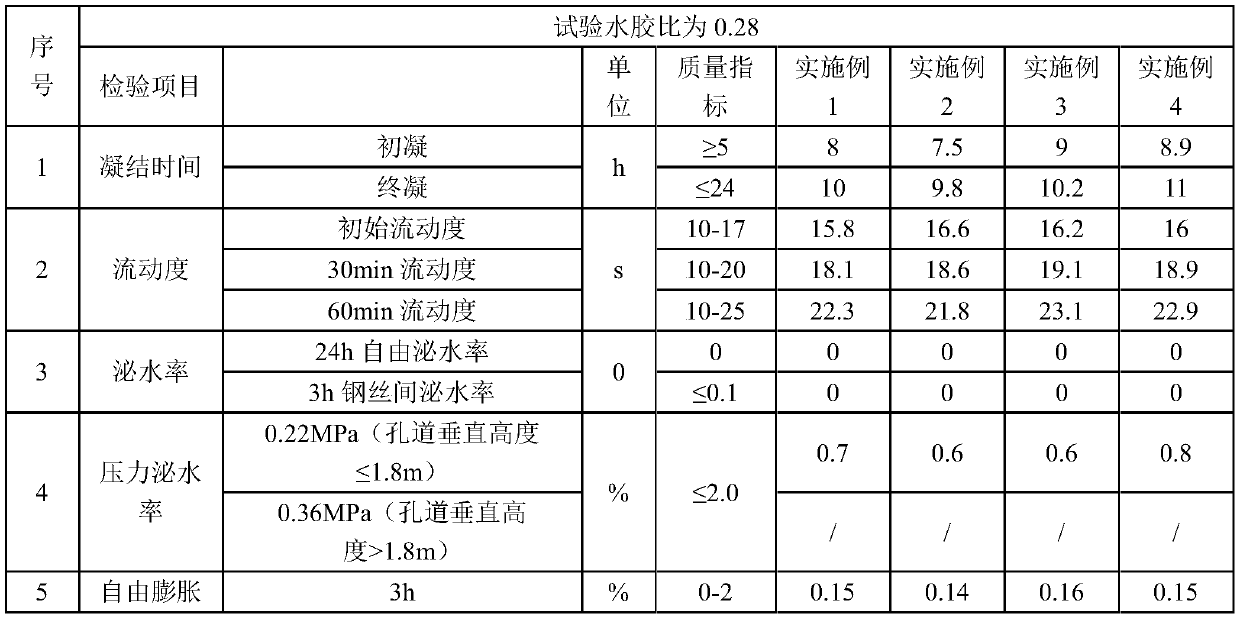

Examples

Embodiment 1

[0031] This example provides a prestressed tunnel pressure slurry, which consists of the following raw materials by weight: 90% ordinary portland cement, 1% ultrafine attapulgite, 1.5% coal gasification residue, 0.008% poly Acrylamide, 0.1% water absorbent resin, 0.2% water reducer, 5% straw ash, 0.3% aluminum powder, 0.008% silane coupling agent, 0.2% defoamer, and the balance is water.

[0032] The preparation method of the above-mentioned prestressed tunnel pressure slurry comprises the following steps:

[0033] Step 1: taking the above-mentioned raw materials by mass;

[0034] Step 2: Spray the weighed water-reducing agent into a uniformly distributed powder, and the fineness is less than 1% with a 100-mesh sieve;

[0035] Step 3: Add an appropriate amount of water to the weighed silane coupling agent to make it into a solution with a concentration of 0.8%, add the weighed aluminum powder, ultrasonically oscillate for 4 minutes, and then stir at 25°C for 2.5 h, filter it...

Embodiment 2

[0038] This example provides a kind of prestressed tunnel pressure slurry, which consists of the following raw materials by weight: 90% ordinary portland cement, 0.5% ultrafine attapulgite, 1.5% coal gasification residue, 0.008% polystyrene Acrylamide, 0.2% water absorbent resin, 0.2% water reducer, 8% straw ash, 0.3% aluminum powder, 0.008% silane coupling agent, 0.2% defoamer, and the balance is water.

[0039] The preparation method of the above-mentioned prestressed tunnel pressure slurry comprises the following steps:

[0040] Step 1: taking the above-mentioned raw materials by mass;

[0041] Step 2: Spray the weighed water-reducing agent into a uniformly distributed powder, and the fineness is less than 1% with a 100-mesh sieve;

[0042] Step 3: Add an appropriate amount of water to the weighed silane coupling agent to make it into a solution with a concentration of 0.8%, add the weighed aluminum powder, ultrasonically oscillate for 4 minutes, and then stir at 25°C for ...

Embodiment 3

[0045] This example provides a prestressed tunnel pressure slurry, which consists of the following raw materials by weight: 92% ordinary portland cement, 0.5% ultrafine attapulgite, 1.5% coal gasification residue, 0.01% poly Acrylamide, 0.2% water absorbent resin, 0.2% water reducer, 8% straw ash, 0.3% aluminum powder, 0.008% silane coupling agent, 0.2% defoamer, and the balance is water.

[0046] The preparation method of the above-mentioned prestressed tunnel pressure slurry comprises the following steps:

[0047] Step 1: taking the above-mentioned raw materials by mass;

[0048] Step 2: Spray the weighed water-reducing agent into a uniformly distributed powder, and the fineness is less than 1% with a 100-mesh sieve;

[0049] Step 3: Add an appropriate amount of water to the weighed silane coupling agent to make it into a solution with a concentration of 0.8%, add the weighed aluminum powder, ultrasonically oscillate for 4 minutes, and then stir at 25°C for 2.5 h, filter it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com