Carbon coated sodium manganese pyrophosphate@graphene oxide composite material with sandwich structure, as well as preparation method and application thereof

A technology of carbon-coated sodium manganese pyrophosphate and composite materials, which is applied to structural parts, electrochemical generators, electrical components, etc., and can solve the problems of poor rate performance and cycle performance, poor material dynamic performance, unfavorable material capacity, etc. problem, to achieve the effect of improving cycle performance, high rate performance, and improving uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

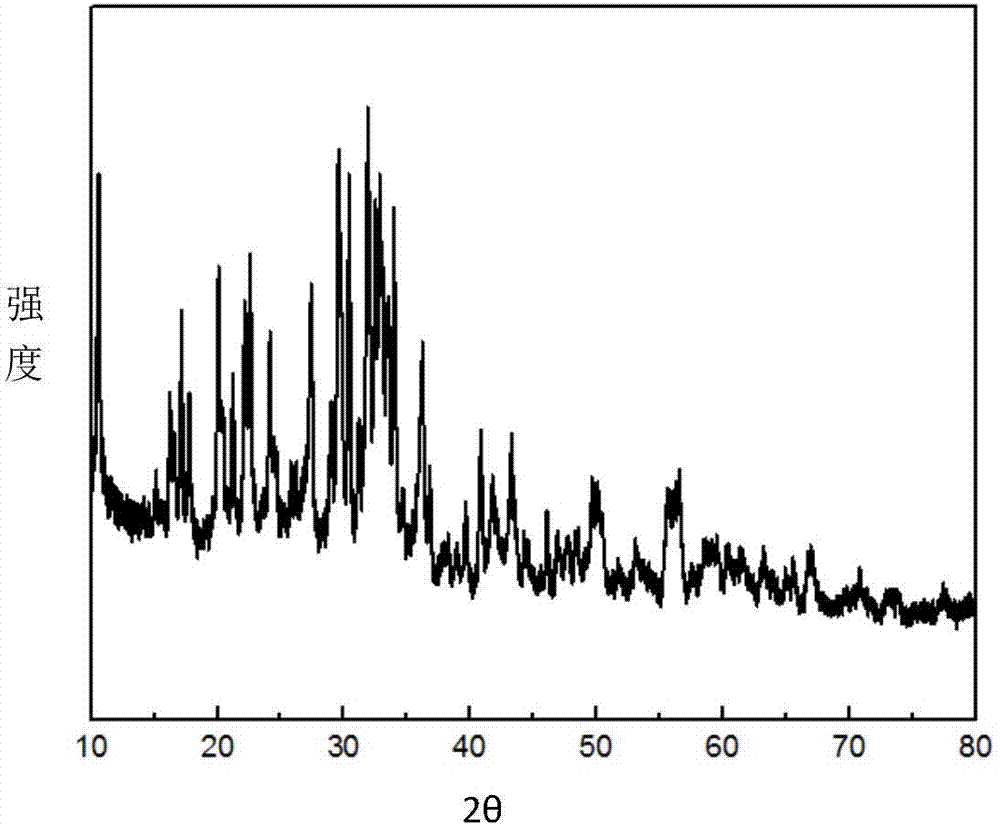

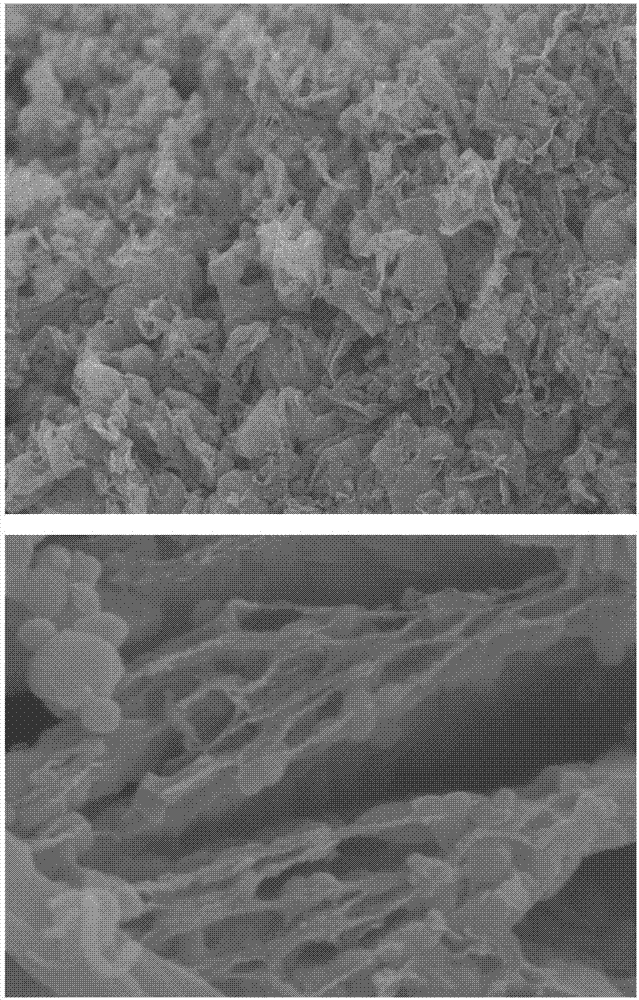

[0042] First, take 0.005mol of manganese acetate tetrahydrate, 0.01mol of ammonium dihydrogen phosphate, 0.005mol of anhydrous sodium carbonate and 2.88g of anhydrous citric acid (3:1 molar ratio to manganese), dissolve them in 50mL of deionized water, and stir thoroughly. A clear solution was obtained. Then 0.067g (5% of the mass of sodium manganese pyrophosphate) graphene oxide was added to the solution, and after ultrasonic treatment for 30min, the solution was placed in a water bath at 80°C for 6h. The solution was frozen in liquid nitrogen, and then placed in a freeze dryer to lyophilize. The obtained precursor was placed in an inert atmosphere tube furnace and sintered at 600°C for 9 hours, and the obtained solid product was a carbon-coated sodium manganese pyrophosphate@graphene oxide composite positive electrode material with a sandwich structure. The X-ray diffraction pattern (XRD) of the prepared "sandwich" structure carbon-coated sodium manganese pyrophosphate@grap...

Embodiment 2

[0045] First, take 0.005 mol of manganese acetate tetrahydrate, 0.01 mol of ammonium dihydrogen phosphate, 0.005 mol of anhydrous sodium carbonate and 3.84 g of anhydrous citric acid (4:1 molar ratio to manganese), dissolve them in 50 mL of deionized water, and stir thoroughly. A clear solution was obtained. Then 0.067g (5% of the mass of sodium manganese pyrophosphate) graphene oxide was added to the solution, and after ultrasonic treatment for 30 minutes, it was placed in a water bath at 80° C. for 6 hours, then frozen in liquid nitrogen, and then placed in a freeze dryer to lyophilize. The obtained precursor was placed in an inert atmosphere tube furnace and sintered at 600°C for 9 hours, and the obtained solid product was a carbon-coated sodium manganese pyrophosphate@graphene oxide composite positive electrode material with a sandwich structure. Sodium manganese pyrophosphate particles have a particle size of 300-500nm and a specific surface area of 110m 2 g- 1 .

[...

Embodiment 3

[0048] First, take 0.005mol of manganese acetate tetrahydrate, 0.01mol of ammonium dihydrogen phosphate, 0.005mol of anhydrous sodium carbonate and 2.88g of anhydrous citric acid (3:1 molar ratio to manganese), dissolve them in 50mL of deionized water, and stir thoroughly. A clear solution was obtained. Then 0.134g (8% of the mass of sodium manganese pyrophosphate) graphene oxide was added to the solution, and after ultrasonic treatment for 30 minutes, it was placed in a water bath at 80° C. for 6 hours, frozen in liquid nitrogen, and then placed in a freeze dryer to lyophilize. The obtained precursor was placed in an inert atmosphere tube furnace and sintered at 600°C for 9 hours, and the obtained solid product was a carbon-coated sodium manganese pyrophosphate@graphene oxide composite positive electrode material with a sandwich structure.

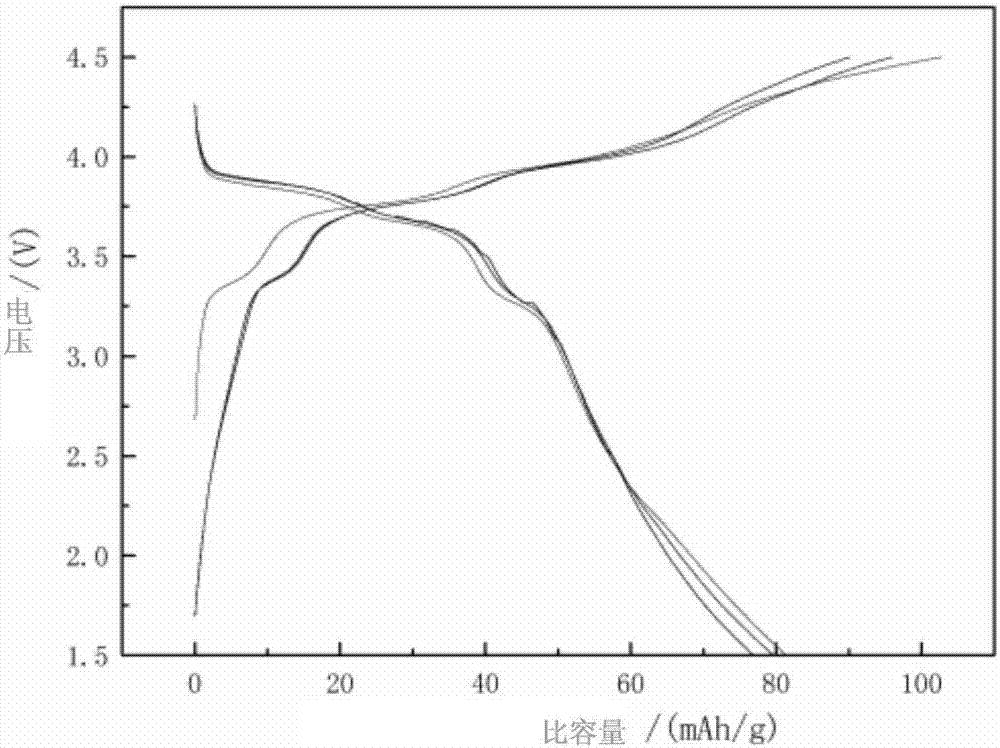

[0049] The sodium ion battery composite positive electrode material prepared in this example and the sodium sheet were assembled into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com