Protein product and preparation method thereof

A protein and protease technology, applied in the field of protein products, to achieve the effect of low corn characteristic odor, wide application range, and broaden types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

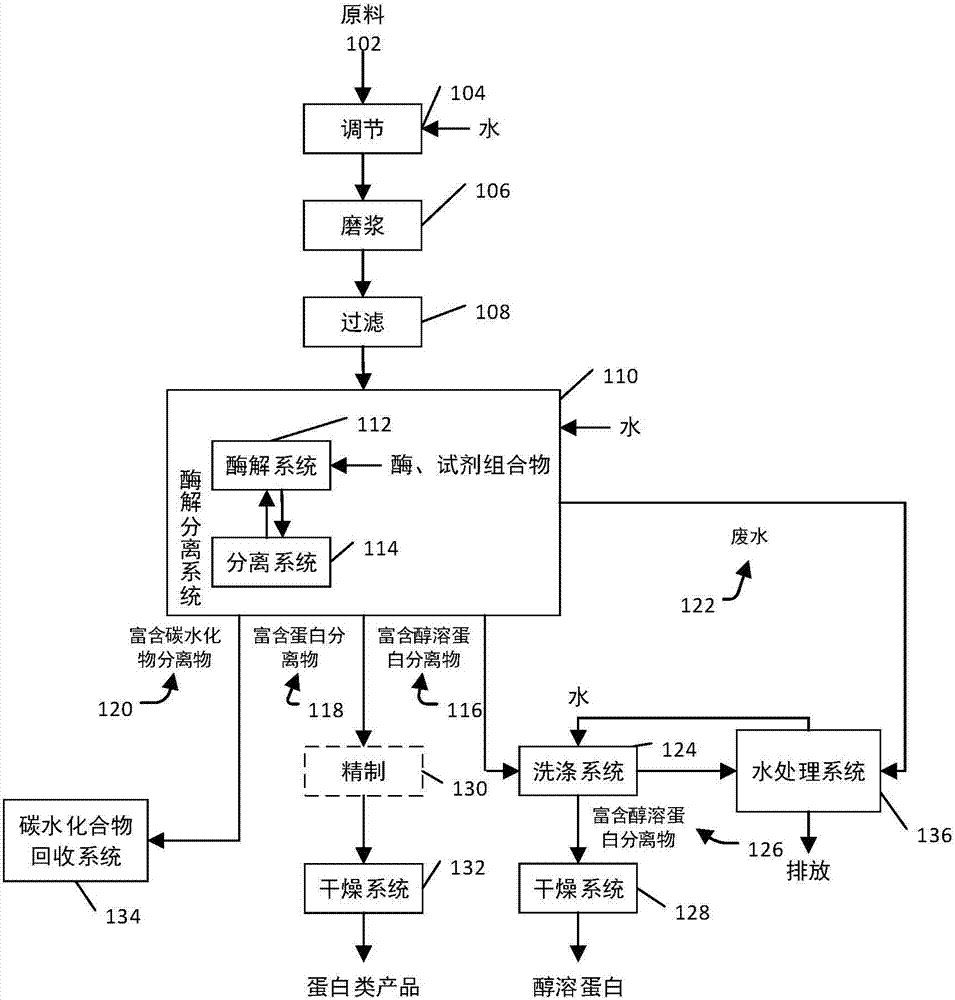

Image

Examples

Embodiment 1

[0075] Water content 8.9%, albumen 64% (dry base) maize yellow powder is adjusted moisture content to 70% and enters enzymolysis tank and adjusts to pH4.8, 45 ℃, and adds the acidic protease ( MA-SD, Amano Enzyme Co., Ltd.), 60mM tris (2-carboxyethyl) phosphine reacted for 1.2 hours and adjusted to pH 7.5, 52 ° C, added 2.6% alkaline protease (2709, Pangbo Bio Engineering Co., Ltd.) and 2% neutral protease (SUKAPro NE, Sukehan Bioengineering Co., Ltd.), 1mM mercaptoethanol reacted for 0.5 hours, centrifuged, washed and collected the precipitate. The dry basis content of the total protein in the obtained product is 61.1%, the gliadin content in the protein is greater than 74%, the alpha-gliadin content is 95%, and the beta-gliadin content is 2%.

Embodiment 2

[0077] Add water to corn yellow powder with 62.4% water content and 70% protein (dry basis) to adjust to 75%, put it into an enzymolysis tank to adjust to pH 3.8, 35°C, and add acid protease (SUKAPro AC Su Cohan Bioengineering Co., Ltd.), 0.26% bromelain (food grade, Pangbo Bioengineering Co., Ltd.), 50mM sodium metabisulfite, 0.5mM tris (2-carboxyethyl) phosphine, and 4mM manganese ions were first reacted for 10 hours, Then raise the temperature to 50°C for 0.5 hours, then adjust to pH 8.3, 52°C, and add 0.33% alkaline protease (2709, Pangbo Bioengineering Co., Ltd.) to react for 1 hour, then add 10mM EDTA and centrifuge, wash and collect precipitation. The dry basis content of the total protein in the obtained product is 54.1%, and the gliadin content in the protein is 97.55%, which contains 95.85% of alpha-gliadin, 1.9% of beta-gliadin and 0.95% of gamma-gliadin.

Embodiment 3

[0079] After adjusting the water content to 80% with the corn yellow powder material containing 89.9% of water and 68% of protein (dry basis), it is put into an enzymolysis tank and adjusted to pH6.5 and 45°C, and papain (foodstuff) containing 0.01% of protein weight is added. Grade, Pangbo Bioengineering Co., Ltd.), 20mM mercaptoethanol and 0.01mM cobalt ion reacted for 1.5 hours, then adjusted to pH 10.2, 45 ℃, and added 0.01% alkaline protease (Protex 6L, Genencor Bio Engineering Co., Ltd.) after reacting for 2 hours, centrifuge, wash and collect the precipitate. The dry basis content of the total protein in the obtained product is 55.9%, and the gliadin content in the protein is greater than 90.66%, which contains 85.54% of α-gliadin, 9.91% of β-gliadin and 4.34% of γ-gliadin .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com