Method for preparing aluminate nanowire array

A nanowire array and aluminate technology, which is applied in the field of preparing aluminate nanowire arrays, to achieve the effect of a large number of products, ingenious principles, and simple heating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

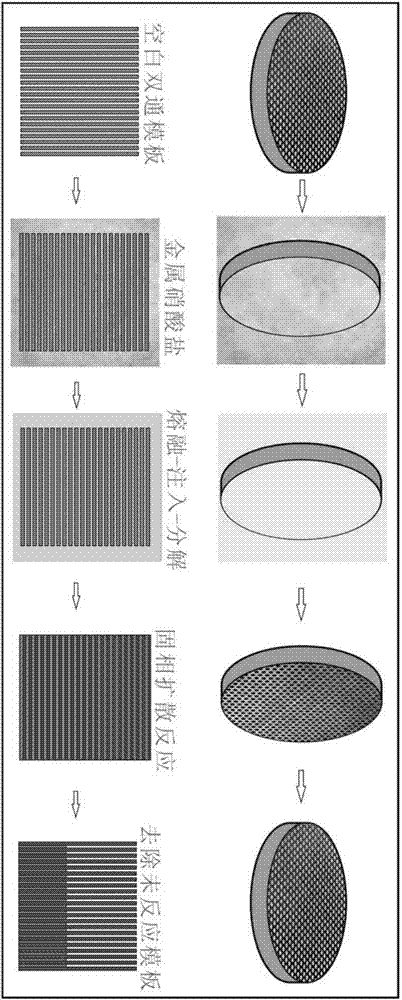

Method used

Image

Examples

Embodiment 1

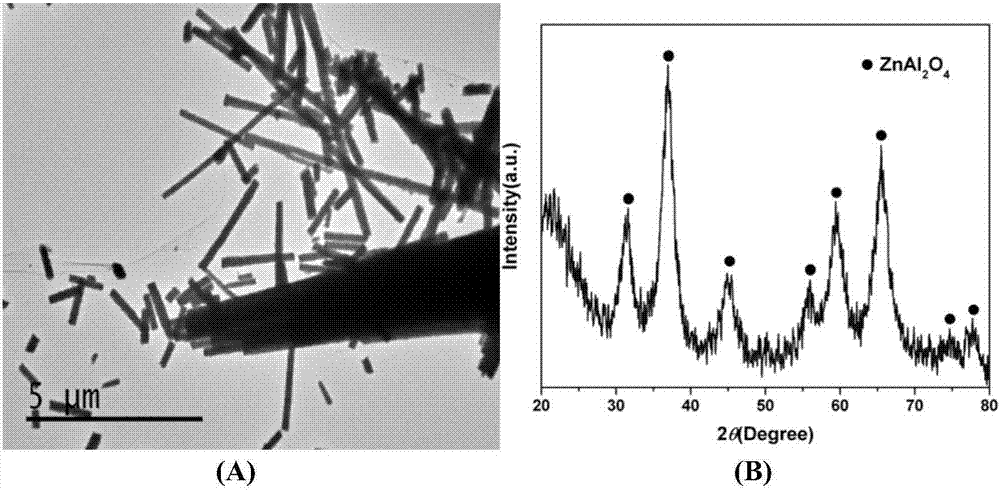

[0040] Zinc aluminate (ZnAl 2 o 4 ) nanowire array

[0041] Zinc nitrate hexahydrate and treated double-pass anodized aluminum template were used as initial reactants. During the preparation, firstly, the double-pass anodized aluminum template is kept vertical as much as possible and fixed into a ceramic crucible with a volume of 50ml. Then, take an appropriate amount of zinc nitrate hexahydrate, grind it evenly in agate, and gently transfer it to a ceramic crucible to bury the anodized aluminum template. Finally, put the ceramic crucible containing the reactants into the muffle furnace. The muffle furnace was slowly raised from room temperature to 350°C at a rate of 5°C / min and kept for 5 hours, then cooled naturally. After the muffle furnace is cooled to room temperature, take out the anodized aluminum template after the reaction, soak it in dilute hydrochloric acid, and then the anodized aluminum template becomes white and transparent, and use 5mol / L hot NaOH solution t...

Embodiment 2

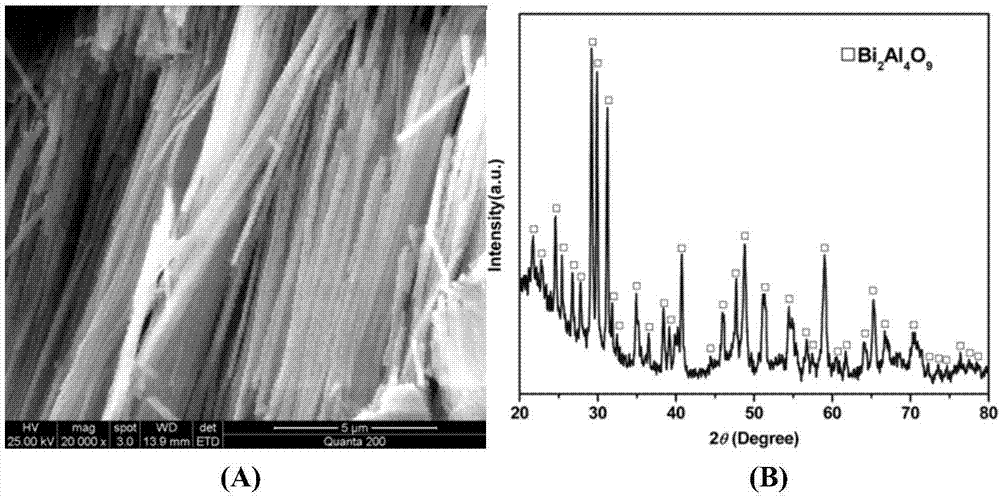

[0043] Bismuth aluminate (Bi 2 Al 4 o 9 ) nanowire array

[0044] Bismuth nitrate pentahydrate and treated double-pass anodized aluminum template are used as initial reactants. During the preparation, firstly, the double-pass anodized aluminum template is kept vertical as much as possible and fixed into a ceramic crucible with a volume of 50ml. Then, take an appropriate amount of bismuth nitrate pentahydrate, grind it evenly in agate, gently transfer it to a ceramic crucible, and bury the anodized aluminum template. Finally, put the ceramic crucible containing the reactants into the muffle furnace. The muffle furnace was slowly raised from room temperature to 650°C at a rate of 5°C / min and kept for 10 hours, then cooled naturally. After the muffle furnace is cooled to room temperature, take out the anodized aluminum template after the reaction, soak it in dilute hydrochloric acid, and turn the anodized aluminum template into light yellow, and use 5mol / L hot NaOH solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com