Novel high-performance glue applicator

A gluing roller, high-performance technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve problems such as bearing lockup, poor sealing of gluing mechanism, glue leakage to the workbench, etc., and achieve reduction The possibility of glue leakage, reducing the amount of glue storage, and better leak-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

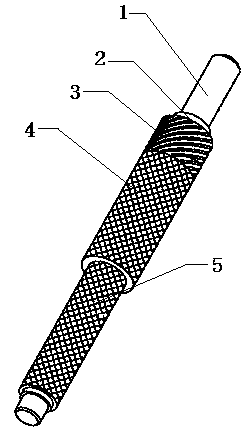

[0012] This embodiment provides a new high-performance gluing roller, which is characterized in that: the high-performance new gluing roller includes a bearing connection part (1), a positioning step surface (2), a spiral expansion plug (3), a supply Rubber cavity (4), glue roller shaft (6);

[0013] Among them: one end of the glue roller shaft (6) is movably connected to install the glue supply chamber (4), and the other end of the glue supply chamber (4) is provided with a spiral expansion plug (3) with the same inner diameter as the glue supply chamber (4), and a bolt expansion plug ( 3) The outer end is fixedly connected to the bearing connection part (1), and the connection part is provided with a positioning step surface (2).

[0014] The bearing connection part (1) is externally connected with a bearing or a driving device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com