Sn-Bi system composite brazing filler metal for electronic packaging and preparation method thereof

A technology for electronic packaging and composite brazing filler metal, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of poor reliability of brazing joints and reduced alloy ductility, and avoid graphene floating and shearing. The effect of strength improvement and shear strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

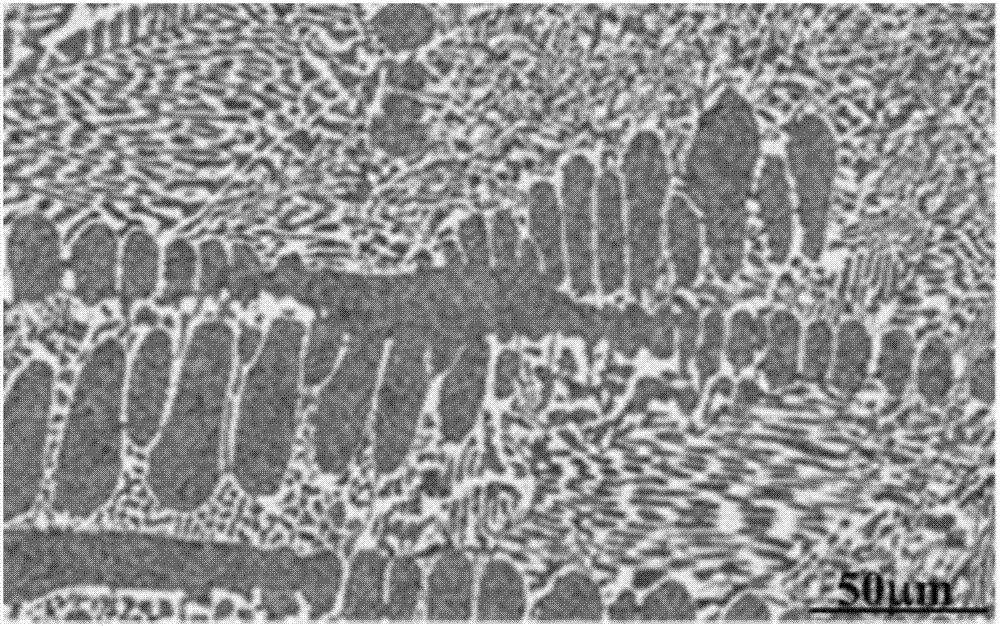

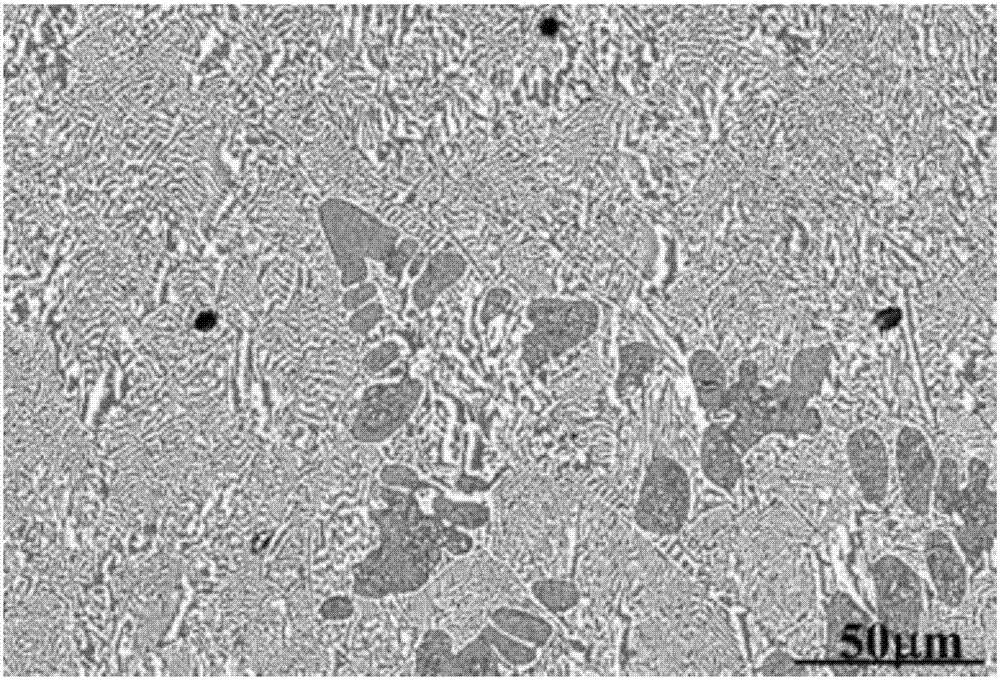

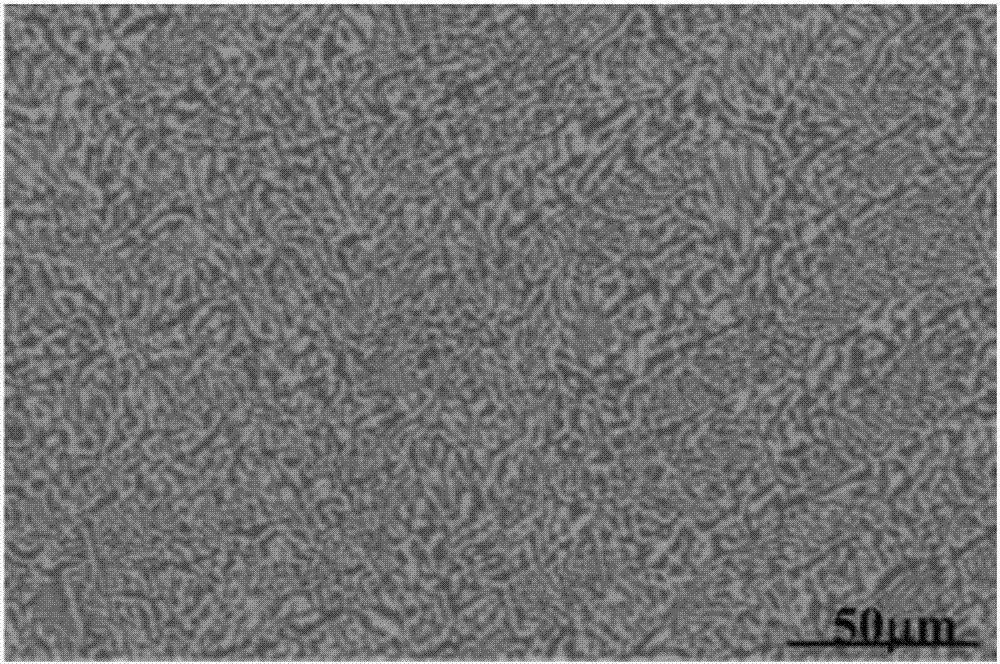

[0018] Specific embodiment one: a kind of Sn-Bi system composite solder for electronic packaging in this embodiment is made up of reinforcement and Sn-58Bi solder; The mass fraction of reinforcement in the Sn-Bi system composite solder for described electronic packaging is: 0.005%-0.5%; the reinforcement is graphene-supported nano-scale cerium oxide or graphene-supported micro-scale cerium oxide, and the mass fraction of graphene in the reinforcement is 30%-90%.

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the particle size of graphene in the graphene-supported nano-scale cerium oxide is 2-10 μm, the thickness is 20-50 nm, and the particle size of nano-scale cerium oxide is 10-20nm; the particle size of the graphene in the graphene-supported micron-sized cerium oxide is 2-10 μm, the thickness is 20-50 nm, and the particle size of the micron-sized cerium oxide is 2-5 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of the reinforcement in the Sn—Bi-based composite solder for electronic packaging is 0.01%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com