Method for preparing water dispersible granules of pesticides

A technology of dispersing granules and pesticide water, applied in the fields of botanical equipment and methods, biocides, animal repellants, etc., can solve the problems of difficulty in forming continuous, automated processes, poor production workshop environment, and high labor intensity of workers, etc. Achieve the effect of low labor intensity, high suspension rate and large active surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

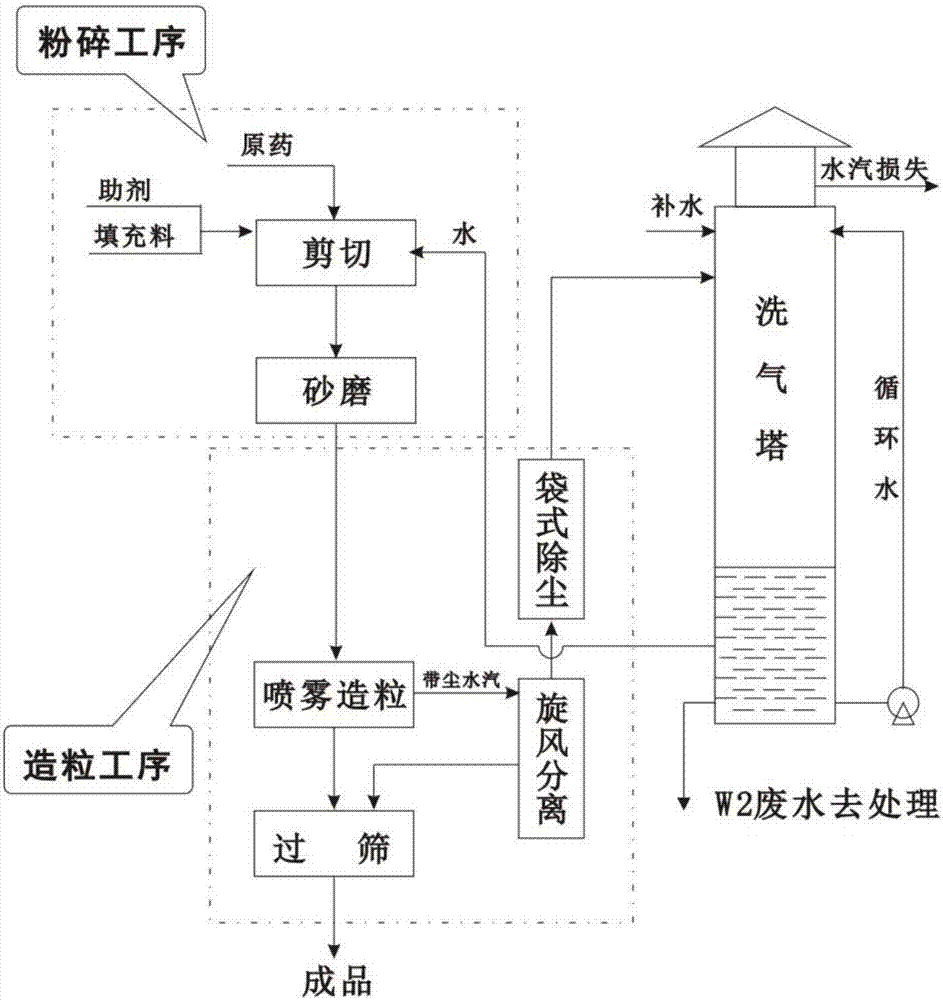

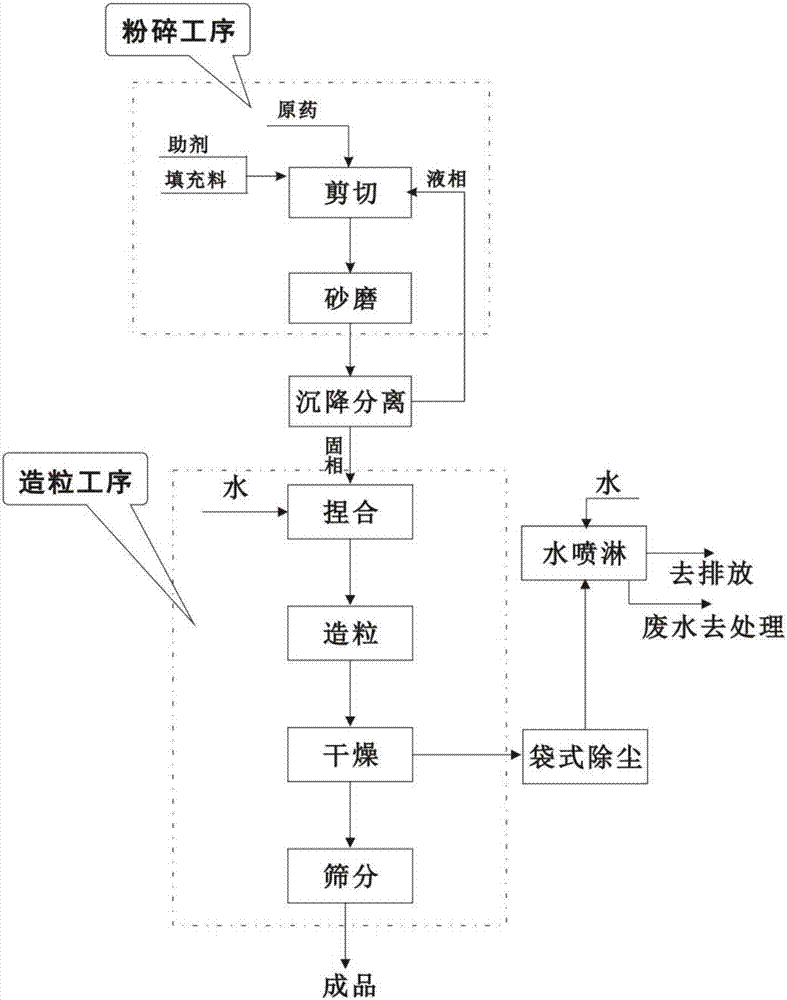

[0046] Figure 4 This is an example of the process flow of the pesticide water dispersible granule production line, in which one or two sets of sand mill and intermediate tank can be connected in series; the kneader can be a rake dryer and a negative pressure dehydration system is installed for further dehydration or direct separation without centrifugation. Concentrate under reduced pressure to a suitable moisture content for granulation.

[0047] The specific operation process is as follows: add the mother liquid separated in the previous batch and the supplementary fresh liquid into the shearing kettle, turn on the shearing kettle to stir, the air pump 1 and the vacuum feeder 1 pulse, and the gear pump 1 is used to assist the grinding of the liquid in sequence Use the vacuum feeder 1 to put solid grinding aids, solid pesticide technicals, fillers, etc. into the shearing kettle, start the external shearing machine to cut the material until the particle size is less than 150 mes...

Embodiment 2

[0054] Example 2: Production of 80% diuron water dispersible granules

[0055] Add 350kg of sand mill mother liquor separated in the previous batch and 110kg of fresh water into the shearing kettle. Turn on the shearing kettle to stir, air pump 1 and vacuum feeder 1 to pulse, and use gear pump 1 to reduce ethylene oxide-propylene oxide in sequence. 5.5kg of block copolymer, use vacuum feeder 1 to put 2.2kg of sodium dodecylbenzene sulfate, 27.4kg of kaolin, and 412.4kg of 97% diuron technical material into the shearing kettle, and start the external shearing machine cycle Cut the material to a particle size of less than 150 meshes, start the dispersion tank and stir, and put the material in the dispersion tank for sand grinding.

[0056] Start the horizontal sand mill, feed the above-mentioned materials into the sand mill through the diaphragm pump attached to the sand mill, adjust the flow rate of the diaphragm pump to ensure the slurry fineness D90 <5um, open the intermediate tan...

Embodiment 3

[0060] Example 3: Production of 80% carbendazim water dispersible granules

[0061] Add 350kg of sand mill mother liquor separated in the previous batch and 105kg of fresh water into the shearing kettle, turn on the shearing kettle to stir, air pump 1 and vacuum feeder 1 to pulse, and use gear pump 1 to ethylene oxide-propylene oxide in sequence Block copolymer 5.3kg, use the vacuum feeder 1 to put 2.1kg of sodium dodecylbenzene sodium sulfate and 408.2kg of 98% carbendazim original drug into the shearing kettle, and start the external shearing machine to cut the material to If the particle size is less than 150 meshes, start the dispersion tank and stir, and put the materials in the dispersion tank for sanding.

[0062] Start the horizontal sand mill, feed the above-mentioned materials into the sand mill through the diaphragm pump attached to the sand mill, adjust the flow rate of the diaphragm pump to ensure the slurry fineness D90 <5um, open the intermediate tank, stir in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com