Grinding wheel and grinding method

A grinding and grinding wheel technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., to achieve effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

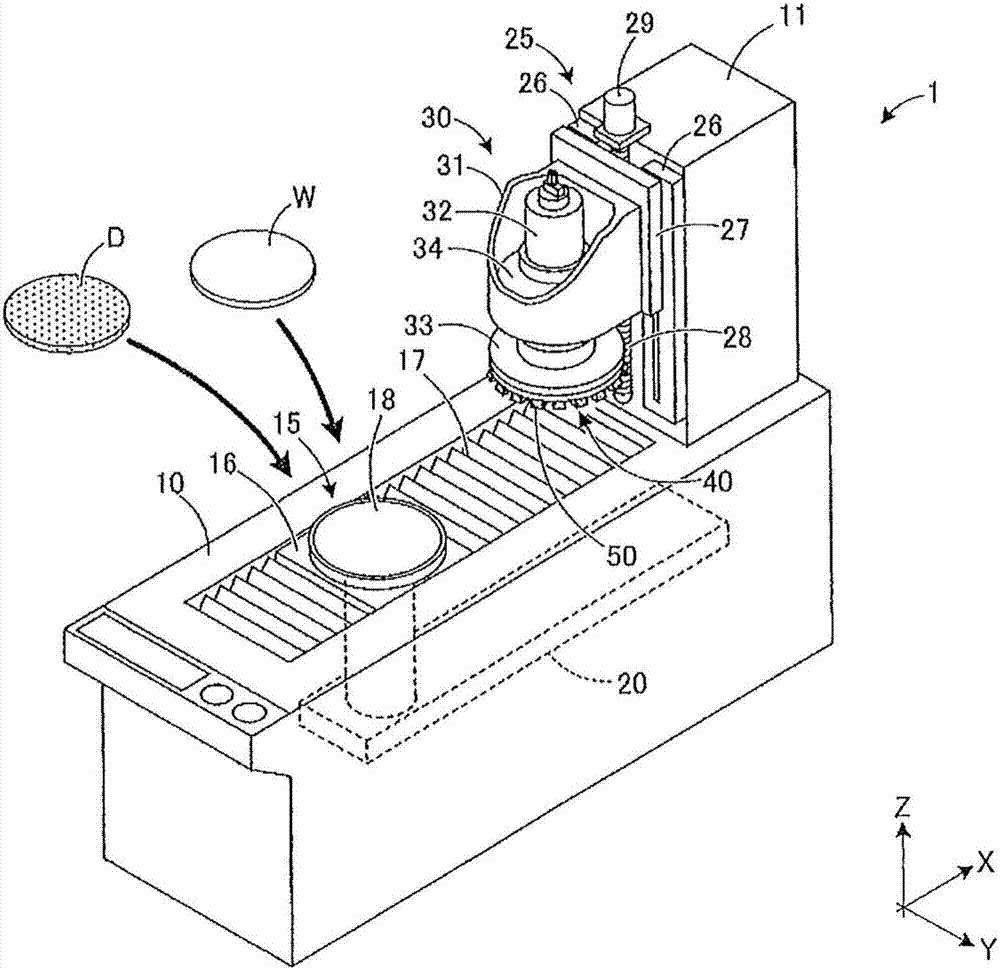

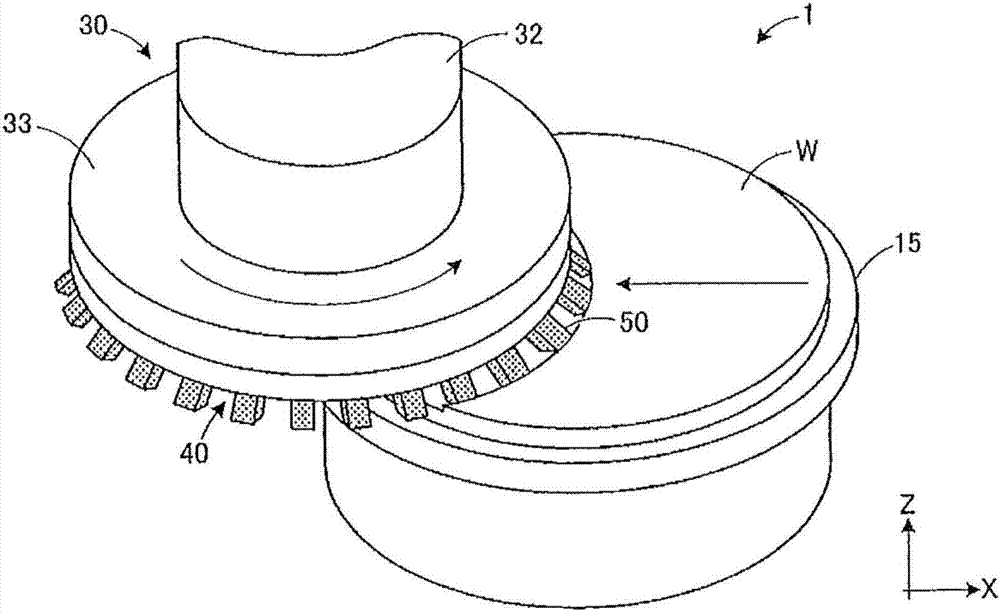

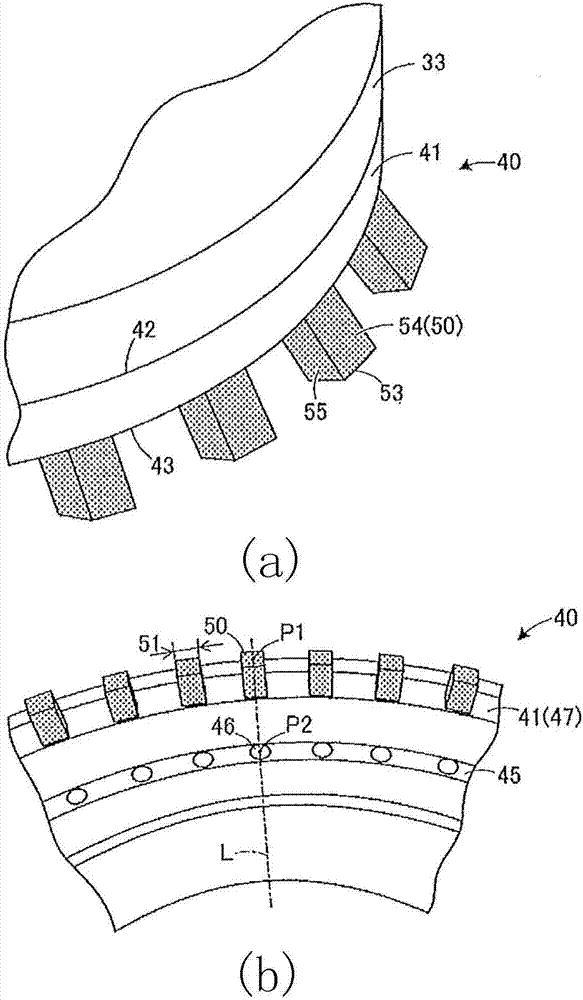

[0050] Hereinafter, experimental examples will be described. In the experimental example, the evaluation workpiece was ground using a grinding wheel in which the blade width and the number of grinding tools were changed, and the state of the grinding surface of the evaluation workpiece was confirmed. Even when the blade width is changed, the number of grinding tools is set so as to be the same as the contact area of the evaluation workpiece. As a grinding wheel, a grinding wheel having a grinding wheel diameter of 200 mm was mounted on a grinding wheel base having the same particle diameter as a metal bonded abrasive, and as an evaluation workpiece, a resin substrate of 130×130 mm was used. In addition, as processing conditions, it implemented according to the following processing conditions.

[0051] Spindle speed: 6000【rpm】

[0052] Feed speed: 10【mm / sec】

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com