Dynamic control method for loop lifting angle of finishing mill

A technology of dynamic control and finishing mill, applied in metal rolling, metal rolling, tension/pressure control, etc. Improved rolling stability and reduced scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

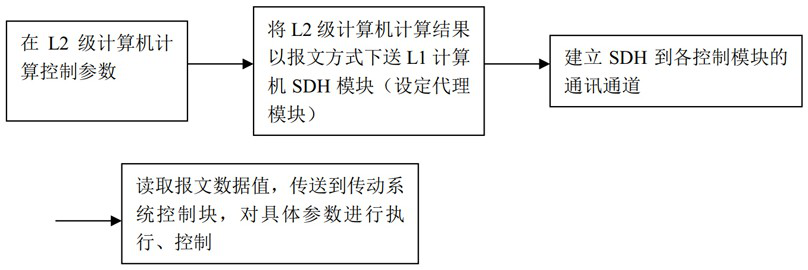

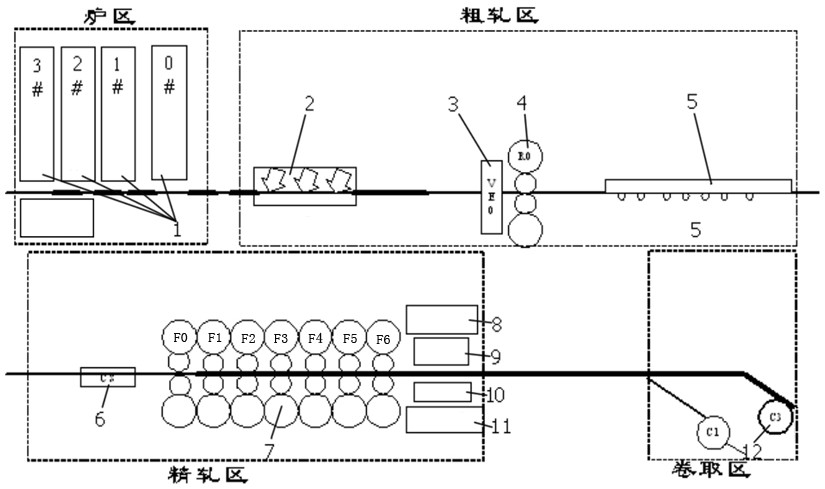

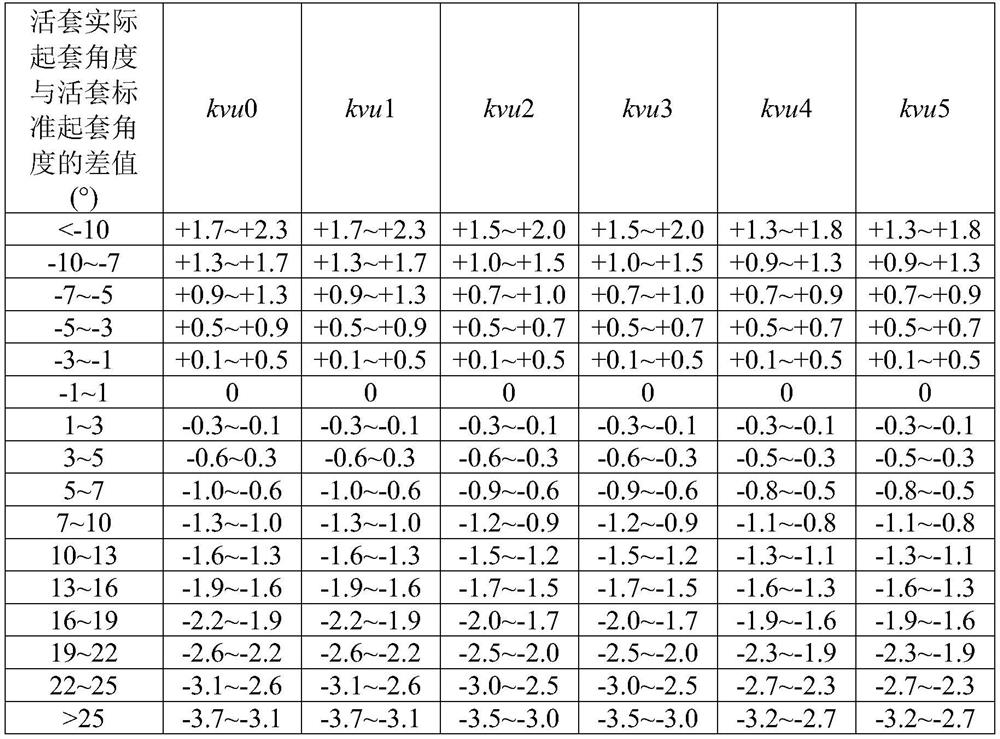

Method used

Image

Examples

Embodiment 1

[0118] In Example 1, plain carbon steel Q195-W was produced, with a target thickness of 2.75 mm and a target width of 1235 mm.

[0119] This piece of steel is the first piece of steel in this batch. The steel coil number is 919059401. The rough rolling exit thickness is 42.709mm, the finish rolling entrance width is 1270.03mm, the rough rolling exit temperature is 1085.2°C, and the finish rolling target temperature is 880°C. The specific composition ( wt.%) is as follows: C: 0.04%, Si: 0.0159%, Mn: 0.2214%, P: 0.007%, S: 0.0132%, Al: 0.000%, Cr: 0.0209%, Ni: 0.0095%, Cu: 0.016% , Mo: 0.0067%, Ti: 0.0010%, V: 0.0017%, Nb: 0.0010%, N: 0.0032%, B: 0%.

[0120] The speed adaptation method of each rack is calculated according to the following steps:

[0121] (1) The exit thickness of rough rolling is 42.709mm, and the reduction rate (%) of each stand F0-F6 of finish rolling is 46.7%, 47.5%, 35.9%, 26.2%, 25.5%, 21.4%, 16.0%. According to formula (4), the outlet thickness (mm) of ...

Embodiment 2

[0175] In Example 2, plain carbon steel Q195-W was produced, with a target thickness of 2.75 mm and a target width of 1235 mm.

[0176] This piece of steel is the second piece of steel in this batch. The coil number is 919059402. The rough rolling exit thickness is 42.707mm, the finish rolling entrance width is 1271.83mm, the rough rolling exit temperature is 1082.5°C, and the finish rolling target temperature is 880°C. The specific composition ( wt.%) is as follows: C: 0.04%, Si: 0.0159%, Mn: 0.2214%, P: 0.007%, S: 0.0132%, Al: 0.000%, Cr: 0.0209%, Ni: 0.0095%, Cu: 0.016% , Mo: 0.0067%, Ti: 0.0010%, V: 0.0017%, Nb: 0.0010%, N: 0.0032%, B: 0%.

[0177] The speed adaptation method of each rack is calculated according to the following steps:

[0178] (1) The exit thickness of rough rolling is 42.707mm, and the reduction rate (%) of each stand F0-F6 of finish rolling is 44.6%, 46.6%, 36.9%, 26.7%, 27.6%, 21.8%, 15.8%. According to formula (4), the outlet thickness (mm) of each ...

Embodiment 3

[0232] In Example 3, common carbon steel DV19A was produced, with a target thickness of 2.45 mm and a target width of 1250 mm.

[0233] This piece of steel is a new steel type, the first piece of steel in this batch, the coil number is 919412801, the rough rolling exit thickness is 40.779mm, the finish rolling entrance width is 1286.04mm, the rough rolling exit temperature is 944.0°C, and the finish rolling target temperature is 830°C. Its specific composition (wt.%) is as follows: C: 0.0029%, Si: 3.0921%, Mn: 0.3138%, P: 0.009%, S: 0.0015%, Al: 0.231%, Cr: 0.0136%, Ni: 0.0047%, Cu: 0.0056%, Mo: 0.0107%, Ti: 0.0022%, V: 0.0022%, Nb: 0.0021%, N: 0.0017%, B: 0%.

[0234] The speed adaptation method of each rack is calculated according to the following steps:

[0235] (1) The exit thickness of rough rolling is 40.779mm, and the reduction rate (%) of each stand F0-F6 of finish rolling is 55.0%, 47.5%, 38.0%, 28.7%, 22.8%, 16.8%, 9.5%. According to formula (4), the outlet thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com