Three-dimensional porous nitrogen-doped graphene and preparation method and application thereof

A nitrogen-doped graphene, three-dimensional porous technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of high preparation conditions, difficulty in large-scale production, and high synthesis cost, so as to improve electrocatalytic activity and activity , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of three-dimensional porous nitrogen-doped graphene, comprising the following steps:

[0028] (1) mixing amino acid with transition metal salt and water to obtain a mixed solution;

[0029] (2) heating the mixed solution obtained in the step (1) to remove moisture under stirring to obtain a solid mixture;

[0030] (3) roasting the solid mixture obtained in the step (2) after grinding to obtain nitrogen-doped carbon powder;

[0031] (4) Grinding the nitrogen-doped carbon powder obtained in the step (3) and sequentially washing with acid, deionized water, absolute ethanol and drying to obtain three-dimensional porous nitrogen-doped graphene.

[0032] The invention mixes amino acid, transition metal salt and water to obtain a mixed solution.

[0033] The present invention does not have any special limitation on the source of the amino acid and the transition metal salt, and commercially available products well known to those sk...

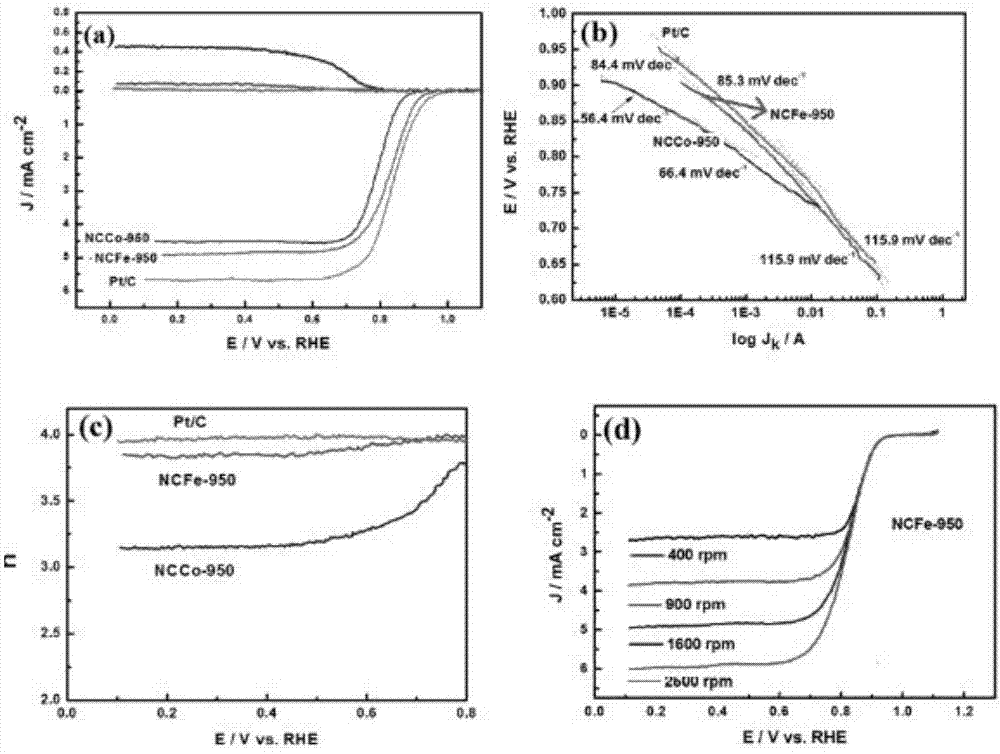

Embodiment 1

[0061] (1) 1g of glycine will be mixed with different proportions of transition metal salt FeCl 3 ·6H 2 O mixed to obtain mixture 1 (glycine: FeCl 3 ·6H 2 The mass ratio of O is 1:1), mixture 2 (glycine:FeCl 3 ·6H 2 The mass ratio of O is 1:2) and mixture 3 (glycine:FeCl 3 ·6H 2 The mass ratio of O is 1:4); mixture 4 (glycine:FeCl 3 ·6H 2 The mass ratio of O is 1:6); mixture 5 (glycine:FeCl 3 ·6H 2 The mass ratio of O is 1:8); mixture 6 (glycine:FeCl 3 ·6H 2 The mass ratio of O is 1:10);

[0062] (2) Add 40 mL of deionized water to the six mixtures of step (1), and stir at room temperature;

[0063] (3) heating the solution in step (2) to 80° C. under stirring until the water is evaporated;

[0064](4) the product in step (3) is put into a quartz boat after being ground, then placed in a tube furnace, under N 2 Under the atmosphere, the temperature was raised to 950°C at a heating rate of 5°C / min, kept for 60 minutes, and then lowered to room temperature at a coo...

Embodiment 2

[0067] (1) Mix 1g glycine with 2g transition metal salt CoCl 2 ·6H 2 O mixed;

[0068] (2) Add 40 mL of deionized water to the mixture in step (1), and stir at room temperature;

[0069] (3) heating the solution in step (2) to 80° C. under stirring until the water is evaporated;

[0070] (4) the product in step (3) is put into a quartz boat after being ground, then placed in a tube furnace, under N 2 Under the atmosphere, the temperature was raised to 950°C at a heating rate of 5°C / min, kept for 60 minutes, and then lowered to room temperature at a cooling rate of 5°C / min to obtain carbon powder;

[0071] (5) The product obtained in step (4) was ground, washed by centrifugation with 1M HCl, washed with deionized water and absolute ethanol until neutral to remove impurities, and placed in a 60°C oven for vacuum drying. The resulting product is denoted as three-dimensional porous nitrogen-doped graphene-7.

[0072] The structural characterization of the three-dimensional po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com