Modified carbon dioxide-based waterborne polyurethane and preparation method thereof

A technology of water-based polyurethane and carbon dioxide, applied in the field of polyurethane, can solve problems such as poor water resistance, poor heat resistance, and difficulty in meeting market requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

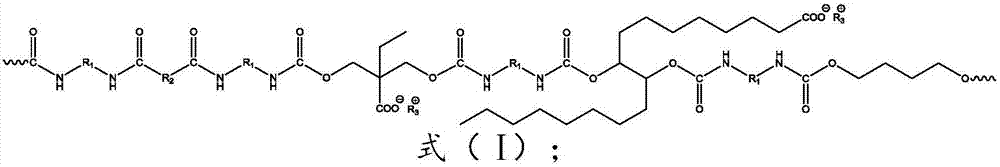

[0044] The present invention also provides the preparation method of above-mentioned modified carbon dioxide-based water-based polyurethane, comprising the following steps:

[0045] A) reacting low-molecular-weight dibasic alcohols with diisocyanates to obtain the first product;

[0046] B) reacting the first product with a hydrophilic chain extender to obtain a second product;

[0047] C) reacting the second product with butanediol to obtain a third product;

[0048] D) performing alkali neutralization, deionized water emulsification, and solvent removal on the third product in sequence to obtain the modified carbon dioxide-based waterborne polyurethane;

[0049] Described low molecular weight dihydric alcohol has the structure shown in formula (2-I):

[0050]

[0051] In formula (2-I), m is preferably 1-30, more preferably 10-25; n is preferably 1-35, more preferably 5-30;

[0052] The diisocyanate is preferably any one of toluene diisocyanate, diphenylmethane diisocya...

Embodiment 1

[0075] According to the method disclosed in Example 9 of the patent 201210086834.X, a carbon dioxide-based diol with a number average molecular weight of 2000 Daltons was prepared.

[0076] Add 100 grams of prepared carbon dioxide-based diols with a molecular weight of 2000 Daltons into a four-neck flask, heat to 110°C, dehydrate at -0.98MPa for 1 hour, cool down to 75°C, and add 150 grams of Butanone and 50 grams of diphenylmethane diisocyanate, add 0.0025 grams of dibutyltin dilaurate catalyst dropwise, react for 2 hours, then add 5 grams of dimethylol butyric acid and 11.9 grams of 9,10-dihydroxystearic acid to react Add 26 grams of butanediol after 1 hour, react for 2 hours, add 3.16 grams of sodium hydroxide to neutralize the pH to 7, then add 210 grams of deionized water, stir at 1200 rpm for 1 hour, remove butanone under reduced pressure, and obtain carbon dioxide Modified waterborne polyurethane resin.

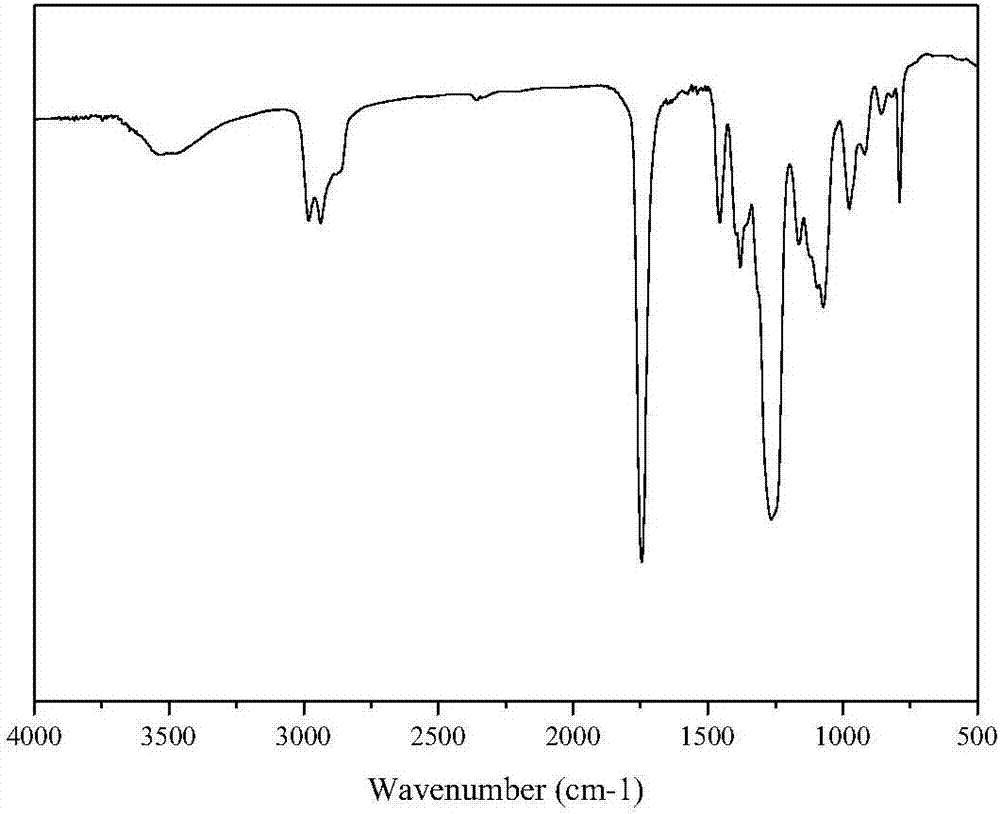

[0077] Infrared detection is carried out to the aqueous polyuret...

Embodiment 2

[0079] According to the method disclosed in Example 8 of the patent 201210086834.X, a carbon dioxide-based diol with a number average molecular weight of 2800 Daltons was prepared.

[0080] Add 168 grams of prepared carbon dioxide-based diols with a molecular weight of 2800 Daltons into a four-neck flask, heat to 110°C, dehydrate at -0.98MPa for 1 hour, cool down to 72°C, and add 150 grams of Butanone and 41.8 grams of toluene diisocyanate, dropwise added 0.0010 grams of dibutyltin dilaurate catalyst, reacted for 2 hours, then added 9 grams of dimethylol butyric acid and 7.08 grams of 9,10-dihydroxystearic acid, after adding React for 1 hour, then 7.8 grams of butanediol, react for 2 hours, add 9 grams of triethylamine to neutralize the pH to 7, then add 230 grams of deionized water, stir at 1200 rpm for 1 hour, remove butanone under reduced pressure, and obtain carbon dioxide Modified waterborne polyurethane resin.

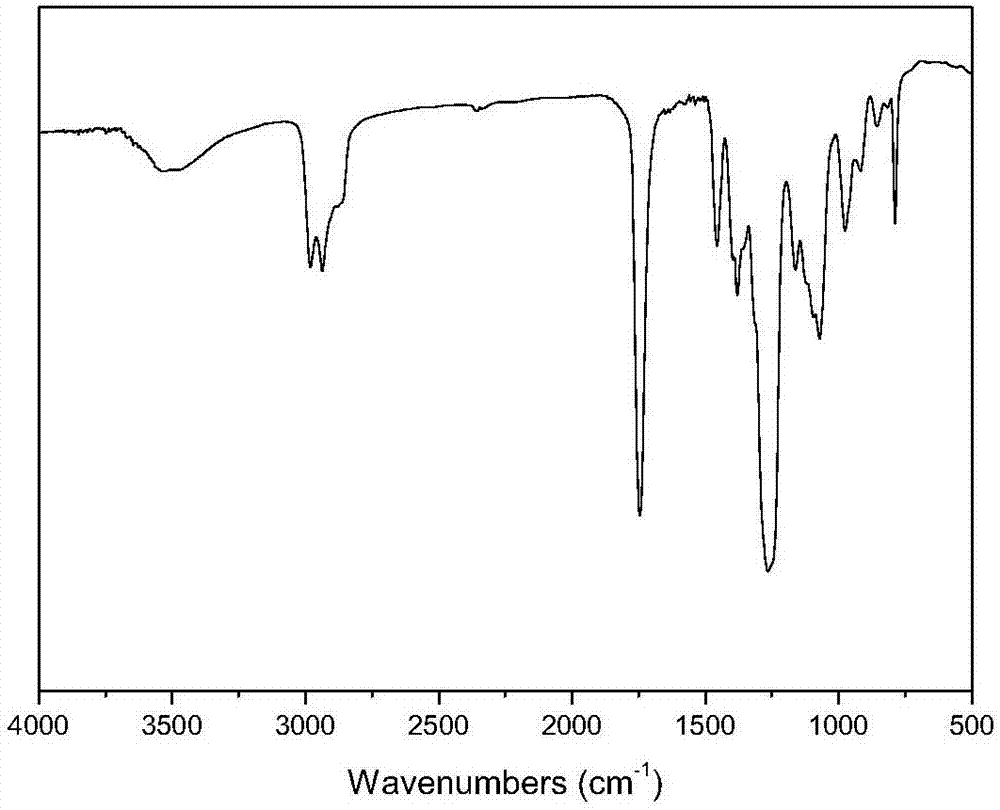

[0081] Infrared detection is carried out to the aqueous po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com