Physalis pubescens food, physalis pubescens polysaccharide and preparation method of physalis pubescens polysaccharide

A technology for physalis and polysaccharide, applied in the direction of food science, etc., can solve problems such as the extraction of active components of physalis and the application is rarely reported, and achieves the effects of improving extraction efficiency and yield, high nutritional value, and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

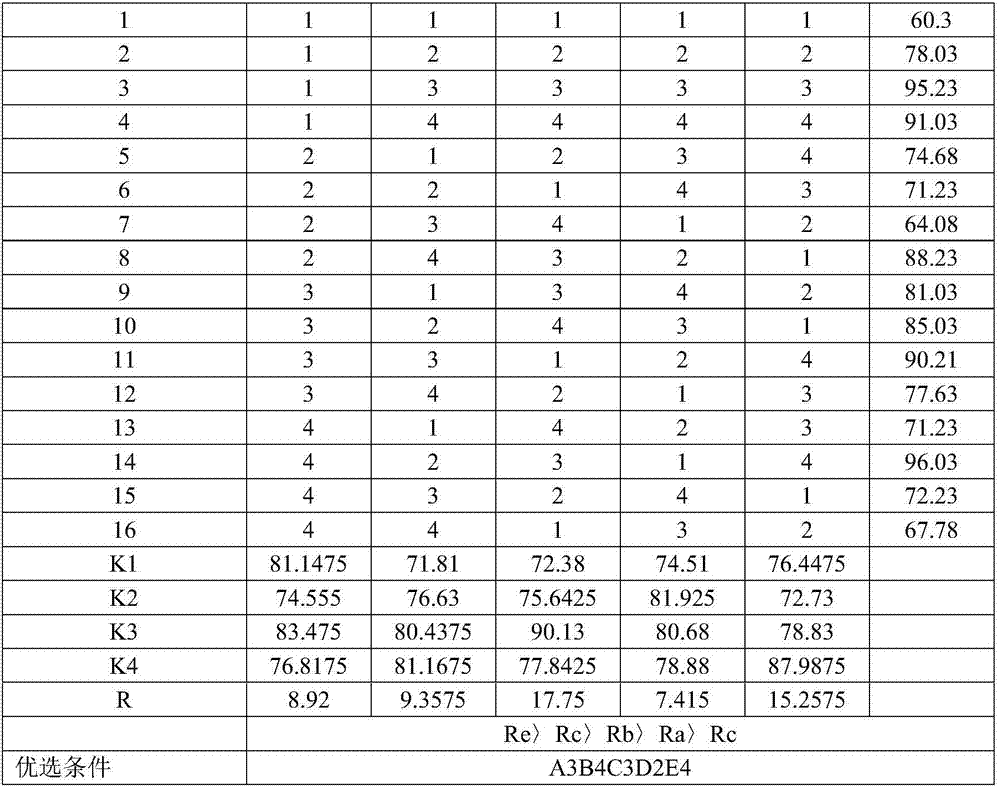

Method used

Image

Examples

preparation example Construction

[0049] The method for preparing Physalis edulis polysaccharide provided by the invention improves the yield of Physalis edulis polysaccharide prepared from Physalis edulis, shortens the production cycle, reduces the production cost, and obtains Physalis edulis polysaccharide with high purity. The yield of the existing Physalis polysaccharide extraction methods, such as the sevage method, is mostly between 3% and 6%, which is significantly lower than that of the extraction method provided by the present invention.

[0050] The present invention also provides a food prepared based on the aforementioned Physalis polysaccharide, that is, Physalis food.

[0051] The raw materials for making physalis food mainly include xylitol and the aforementioned polysaccharides of physalis. Optionally, the physalis food also includes low-gluten flour and butter.

[0052] The method for making the physalis food comprises: melting butter at room temperature, adding physalis polysaccharides and x...

Embodiment 1

[0056] A kind of physalis polysaccharide, its preparation method is as follows:

[0057] After the fresh physalis is washed, it is pulverized to obtain fruit pulp. Mix the fruit pulp with pectinase and cellulase, stand at 50°C for enzymolysis, then filter and remove residue to obtain the enzymolysis material. The enzymolysis material and maltodextrin are mixed evenly with water to obtain an aqueous solution with an enzymolysis material content of 25 wt % and a maltodextrin content of 8 wt %. The conditions for spray drying to obtain powder materials by spray drying are: aqueous solution feed flow rate 5mL / min, air inlet temperature 1600°C, exhaust air volume 20m 3 / h. Dissolve the powder and abrasive in distilled water, and then perform ultrasonic extraction with a countercurrent ultrasonic device under the conditions of 80° C. and a frequency of 20,000 Hz by a supersonic extraction method to obtain an extract. The extract is dispersed in ethanol, and after precipitation oc...

Embodiment 2

[0059] A kind of physalis polysaccharide, its preparation method is as follows:

[0060] After the fresh physalis is washed, it is pulverized to obtain fruit pulp. Mix the fruit pulp with pectinase and cellulase, stand at 65°C for enzymolysis, then filter and remove residue to obtain the enzymolysis material. The enzymolyzed material and maltodextrin are mixed evenly with water to obtain an aqueous solution with an enzymatically hydrolyzed material content of 50 wt % and a maltodextrin content of 8-15 wt %. The conditions for spray drying to obtain powder materials by spray drying are: the feed flow rate of aqueous solution is 10mL / min, the air inlet temperature is 1200°C, and the exhaust air volume is 50m 3 / h. Dissolve the abrasive material in distilled water, and then perform ultrasonic extraction with a countercurrent ultrasonic device under the conditions of 90° C. and a frequency of 40,000 Hz by a supersonic extraction method to obtain an extract. The extract is dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com