Sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars and construction method thereof

A technology of mixing reinforcement and concrete beams, applied in the direction of joists, girders, trusses, etc., can solve the problem of affecting the bearing and service performance of FRP reinforced concrete components, restricting the promotion and application of FRP reinforced concrete components, and wasting fresh water resources and manpower. Financial resources and other issues can be solved to solve the lack of river sand building materials, omit processing procedures, and improve the safety and service life of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

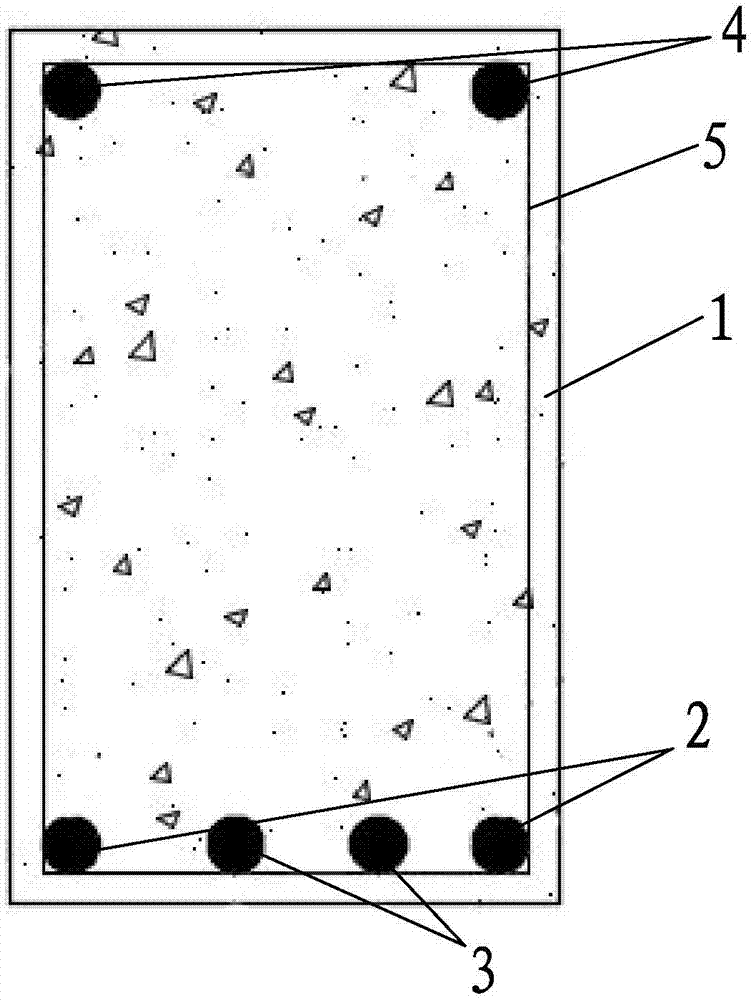

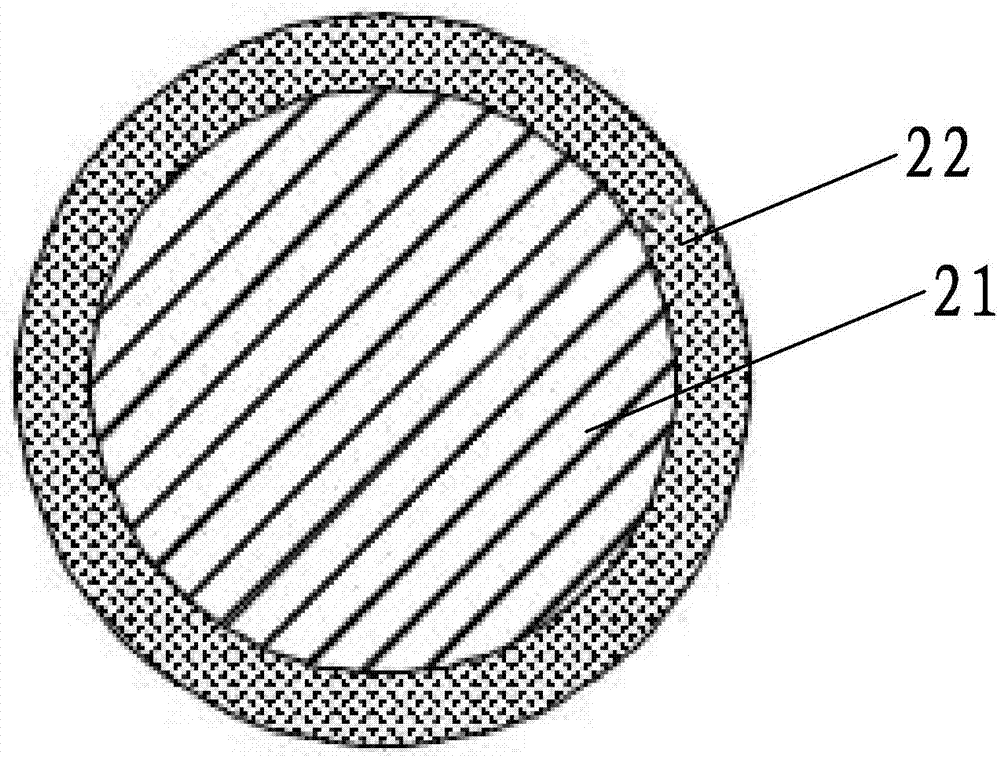

[0033] refer to figure 1 and image 3 , this embodiment relates to a sea-sand concrete beam, and the cross-section of the beam can be rectangular, or T-shaped or box-shaped. It includes sea sand concrete 1 and FRP-steel composite bars 2, FRP bars 3, erecting bars 4 and stirrups 5 fixed in sea sand concrete 1, and the FRP-steel composite bars 2 and FRP bars 3 are set in the The lower end of the sea sand concrete 1, the erecting bar 4 is arranged on the upper end of the sea sand concrete 1, the length of the FRP-steel composite bar 2 and the FRP bar 3 is set along the length of the sand concrete 1; the hoop The reinforcement 5 is a ring structure, and the stirrups 5 are set to be multiple, and are evenly fixed and bound to the FRP-steel composite reinforcement 2, FRP reinforcement 3 and On the outer surface of erecting bar 4 ; the FRP-steel composite bar 2 includes steel bar 21 and FRP fiber cloth 22 coated on the outer surface of steel bar 21 , and the FRP fiber cloth 22 is f...

Embodiment 2

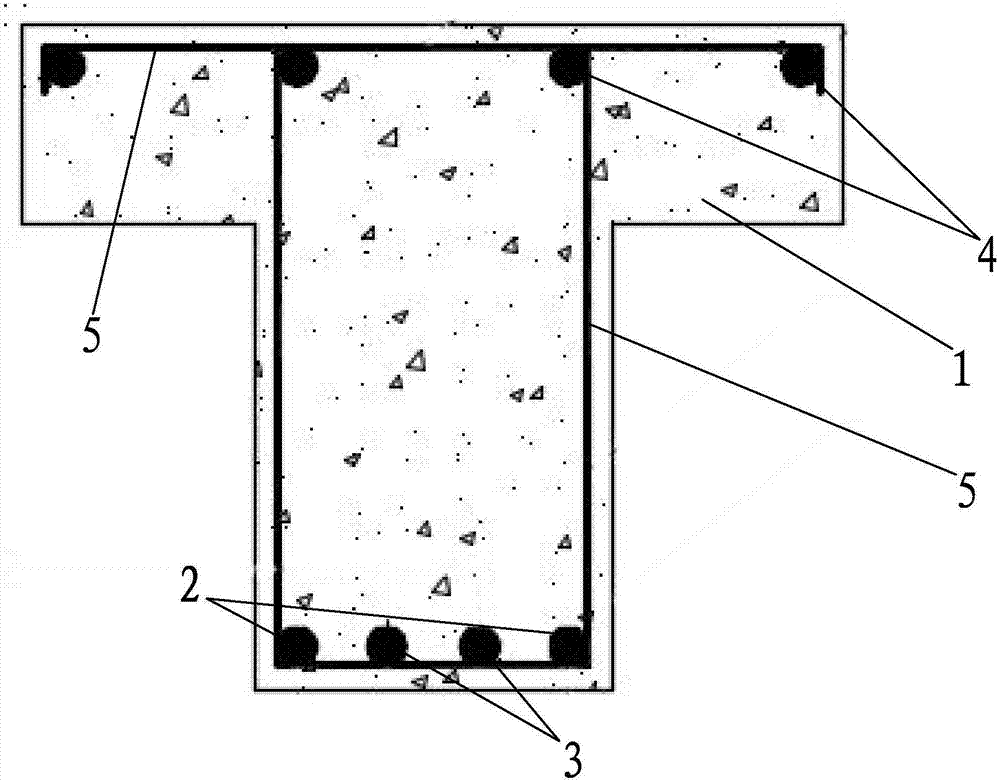

[0053] This embodiment is on the basis of Embodiment 1, as an improvement to the setting structure of erecting bars, such as figure 2 As shown, the cross-section of the sea-sand concrete is a T-shaped structure, and the erection bars are set as multiple, and evenly arranged on the upper part of the sea-sand concrete; the erection bars are fixedly bound together by stirrups, and the erection bars are connected with FRP-steel composite bars 2 and FRP bars 3 are also fixedly connected together by stirrups. The erecting bars of this structure are individually bound by stirrups to form an integral bar structure, which greatly improves the ability of the erecting bars to withstand pressure.

Embodiment 3

[0055] Present embodiment is on the basis of embodiment 1, as the improvement to the setting structure of FRP-steel composite bar 2, as Figure 4 As shown, the FRP-steel composite bars 2 are arranged in two rows, and the FRP-steel composite bars 2 are fixedly connected to the inner ring of the stirrup 5 . The structure uses multiple rows of FRP-steel composite bars 2 as support, which greatly improves the ability of the beam to withstand tension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com