Dry connection method of concrete slab and steel beam of steel-concrete composite beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The first specific embodiment of the present invention is a method for connecting a concrete slab and a steel beam of a steel-concrete composite beam, the steps of which are:

[0036] A method for dry connection of a concrete slab and a steel beam of a steel-concrete composite beam, the steps of which are:

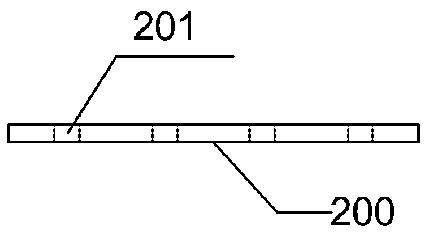

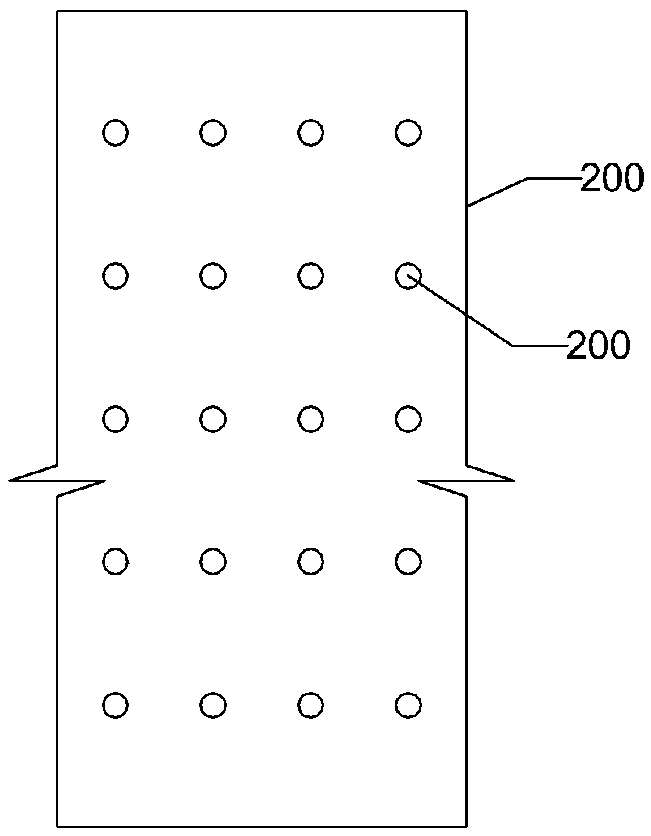

[0037] A. Production of positioning templates

[0038] On the steel plate with the same width as the upper flange plate 400 of the steel beam, the positioning holes 201 are drilled according to the spacing of the connecting rods 103 of the steel-concrete composite beam to form a positioning template 200; see Figure 1a , Figure 1b and image 3 .

[0039] B. Production of steel plate connectors

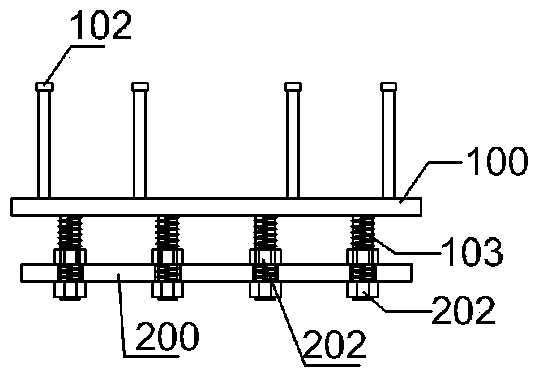

[0040] Welding the lower end of the shear connector 102 to the upper surface of the connecting plate 100 having the same width as the upper flange plate 400 of the steel beam;

[0041] Insert the connecting rod 103 into the positioning hole of the positioning template 2...

Embodiment 2

[0049] The second specific embodiment of the present invention is a method for connecting a concrete slab and a steel beam of a steel-concrete composite beam, the steps of which are:

[0050] A. Production of positioning templates

[0051] On the steel plate with the same width as the upper flange plate 400 of the steel beam, the positioning holes 201 are drilled according to the spacing of the connecting rods 103 of the steel-concrete composite beam to form the positioning template 200;

[0052] B. Production of steel plate connectors

[0053] Welding the lower end of the shear connector 102 to the upper surface of the connecting plate 100 having the same width as the upper flange plate 400 of the steel beam;

[0054]Insert the connecting rod 103 into the positioning hole of the positioning template 200, fix the connecting rod 103 and the positioning template 200 with a temporary fastener 202, then fix the connecting rod 103 to the lower surface of the connecting plate 100, ...

Embodiment 3

[0062] A third embodiment of the present invention is a method for connecting a concrete slab of a steel-concrete composite beam to a steel beam, the steps of which are:

[0063] A method for dry connection of a concrete slab and a steel beam of a steel-concrete composite beam, the steps of which are:

[0064] A. Production of positioning templates

[0065] On the steel plate with the same width as the upper flange plate 400 of the steel beam, the positioning holes 201 are drilled according to the spacing of the connecting rods 103 of the steel-concrete composite beam to form the positioning template 200;

[0066] B. Production of steel plate connectors

[0067] Welding the lower end of the shear connector 102 to the upper surface of the connecting plate 100 having the same width as the upper flange plate 400 of the steel beam;

[0068] Insert the connecting rod 103 into the positioning hole of the positioning template 200, fix the connecting rod 103 and the positioning temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com