High-water-resistant colorful stone-like paint

A technology of water resistance and real stone paint, applied in coatings, anti-corrosion coatings, etc., can solve the problems of high water absorption, whitening and softening of coatings, color changes and other problems of real stone paint, and achieve good weather resistance, excellent construction performance and hardness big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

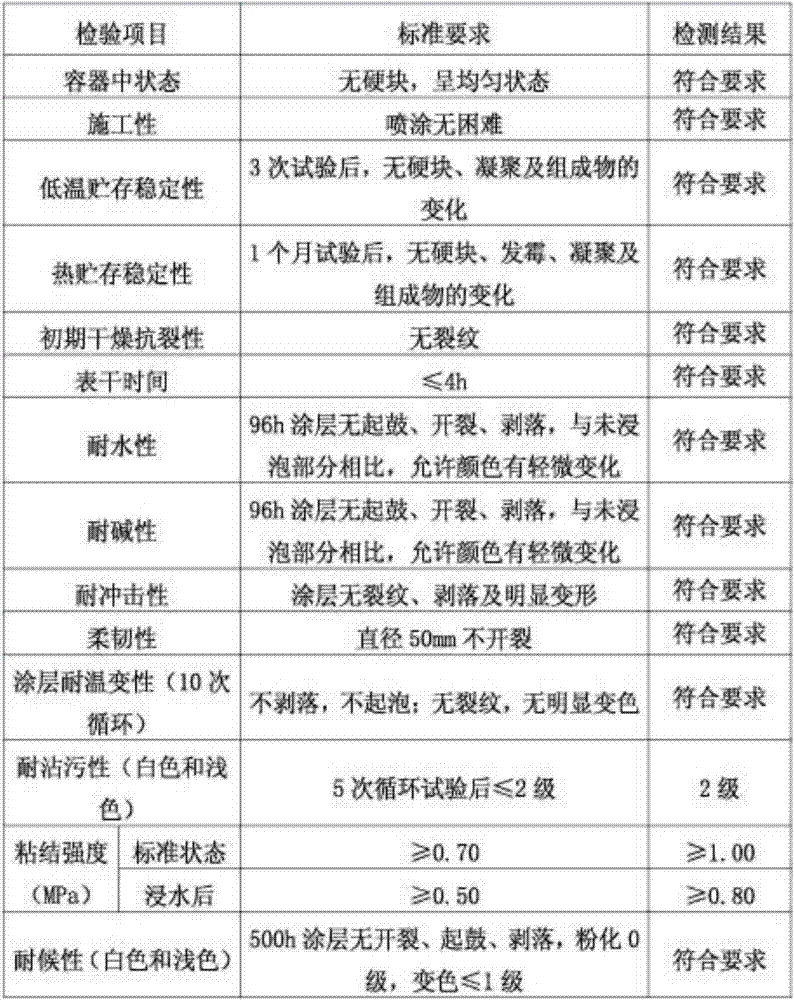

Examples

Embodiment 1

[0022] A kind of highly water-resistant colorful real stone paint, comprising the following raw materials in parts by mass:

[0023] 8 parts of hexanediol butyl ether acetate, 70 parts of sintered colored sand, 4 parts of Shuangfei powder, 23 parts of silicone acrylic emulsion, 0.5 parts of silicone water repellent, 2 parts of polyamide wax, 5 parts of polyethylene wax, 2.5 parts of sodium benzoate 4 parts of kaolin, 4.5 parts of ethylene glycol, 3.5 parts of calcium chloride, 1 part of acrylic dispersant, 3.5 parts of sodium hexametaphosphate solution, and 30 parts of water.

Embodiment 2

[0025] A kind of highly water-resistant colorful real stone paint, comprising the following raw materials in parts by mass:

[0026] 12 parts of hexanediol butyl ether acetate, 130 parts of sintered colored sand, 8 parts of Shuangfei powder, 20 parts of silicone acrylic emulsion, 2.5 parts of silicone water repellent, 4 parts of polyamide wax, 4 parts of polyethylene wax, 6.5 parts of sodium benzoate 8 parts of kaolin, 1.5 parts of ethylene glycol, 4.5 parts of calcium chloride, 2.5 parts of acrylic dispersant, 1 part of sodium hexametaphosphate solution, and 50 parts of water.

Embodiment 3

[0028] A kind of highly water-resistant colorful real stone paint, comprising the following raw materials in parts by mass:

[0029] 9 parts of hexanediol butyl ether acetate, 90 parts of sintered colored sand, 6 parts of Shuangfei powder, 22 parts of silicone acrylic emulsion, 2 parts of silicone water repellent, 3 parts of polyamide wax, 4 parts of polyethylene wax, 5 parts of sodium benzoate 5 parts of kaolin, 2 parts of ethylene glycol, 4 parts of calcium chloride, 2 parts of acrylic dispersant, 2 parts of sodium hexametaphosphate solution, and 40 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com