Five-axis 3D printer

A 3D printer and printing seat technology, applied in the coating device, processing drive device, additive processing, etc., can solve the problems of high consumables and low printing efficiency, and achieve the goal of reducing printing cost, simple structure and improving printing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

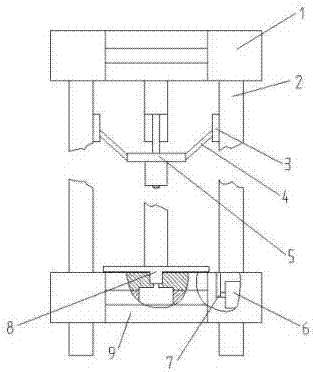

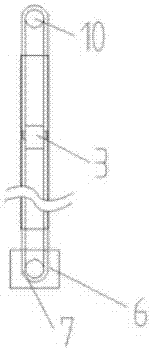

[0040] likefigure 1 As shown, a five-axis 3D printer includes a connecting frame, a printing body 5, a printing seat 8, and a driving motor; the printing body 5 and the printing body are connected to the connecting frame, and are respectively connected to the corresponding driving motor, and the connecting frame The body includes an upper frame body 1 and a lower frame body 9; the printing body 5 is connected to the upper frame body 1, and the printing seat 8 is connected to the lower frame body 9; the upper frame body 1 and the lower frame body 9 are connected by three columns 2 , the printing body 5 is respectively connected with the three columns 2 through the connecting rod 4, and can move up and down relative to the columns 2; the printing body 5 is also connected with a horizontal rotation mechanism, which can make the printing body move in any direction in the X and Y axes. One axis rotates horizontally at a certain angle to realize lateral printing of suspended structur...

Embodiment 2

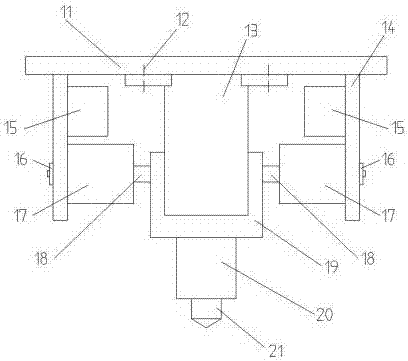

[0042] like image 3 As shown, a five-axis 3D printer based on Embodiment 1, its printing body 5 includes a connecting plate 11, a heat dissipation block 13, a nozzle seat 19 and a printing nozzle 21; the connecting plate 11 is connected with the connecting rod 4; the connecting plate 11, heat dissipation The block 13 and the print nozzle 21 are connected sequentially from top to bottom; the print nozzle 21 is also provided with a nozzle seat 19, and the print nozzle 21 is connected with the heat dissipation block 13 through the nozzle seat 19; the nozzle seat 19 is connected with the horizontal rotation mechanism; A heating block 20 is also provided between the printing nozzles 21 ; through holes are provided on the connecting plate 11 and the heating block 20 , and a guide wire cavity corresponding to the position of the through hole is provided in the heat dissipation block 13 . The lower end of the cooling block 13 is an arc-shaped end face; Figure 5 As shown, the guide ...

Embodiment 3

[0044] like image 3 As shown, a five-axis 3D printer based on Embodiment 2, its horizontal rotation mechanism includes a support frame 14, a rotating shaft 2 18 and a motor 2 17; the support frame 14 is connected to the connecting plate 11, and the support frame 14 is provided with a motor 2 17 Motor two 17 is connected with shower head seat 19 by rotating shaft two 18; The horizontal rotation mechanism is provided with two groups, which are symmetrically arranged on both sides of the nozzle seat 19; a cooling device 15 is also provided above the inner wall of the support frame 14, and there are two groups of cooling devices 15, which are symmetrically arranged on both sides of the cooling block 13; Figure 4 As shown, the horizontal turning mechanism and the cooling device 15 are connected to each other by screws 12, 16, 22 to ensure the relative stability of their connection positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com