Printing medium height adjustment control method and printing device

A printing medium and height adjustment technology, applied in printing devices, printing, typewriters, etc., can solve problems such as damage, cumbersome operation, waste of machinery, etc., and achieve the effects of improving accuracy, simplifying operation, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the content of the present invention, the present invention will be described in more depth and in detail through the description of specific embodiments below in conjunction with the accompanying drawings.

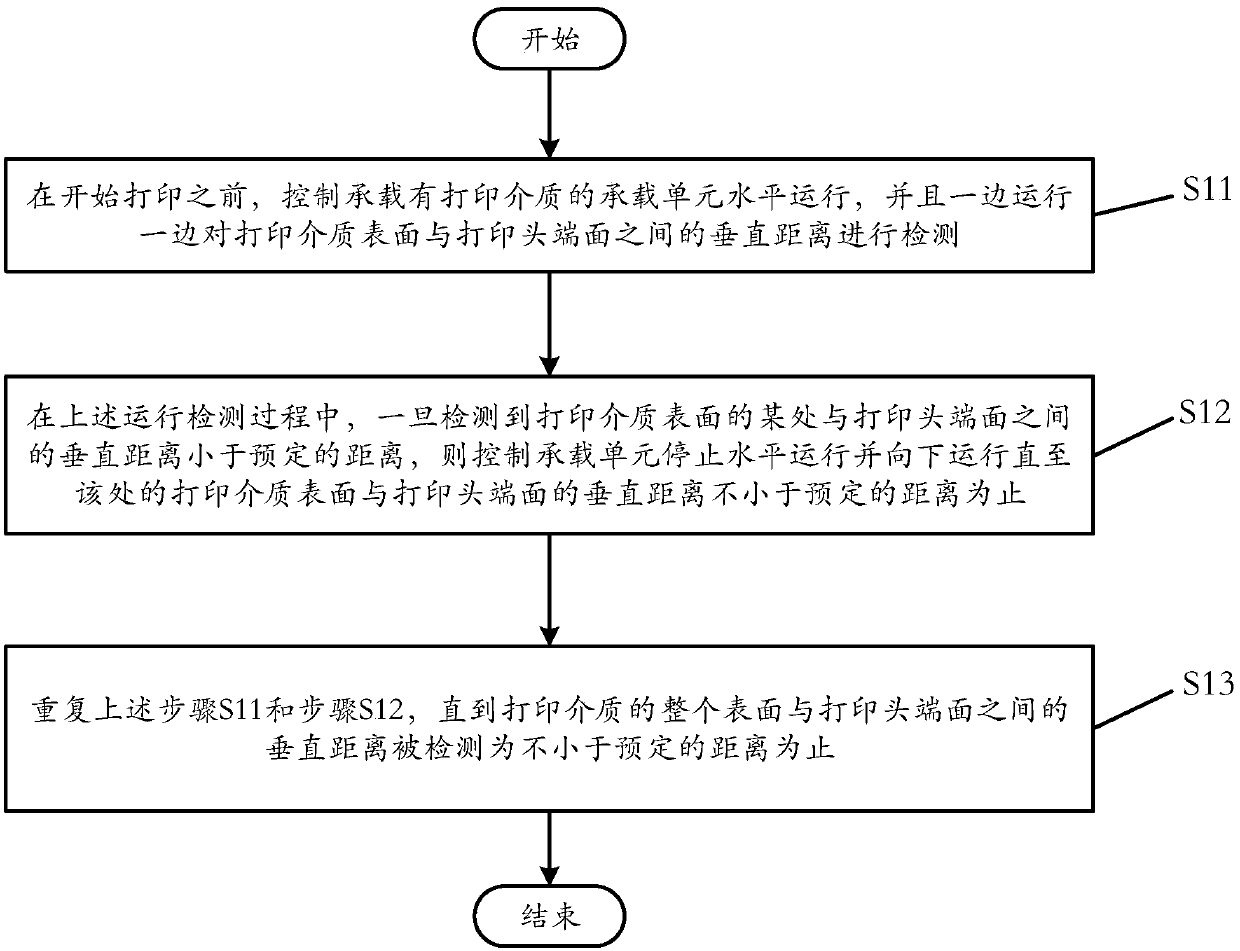

[0037] According to one aspect of the present invention, a method for adjusting and controlling the height of a printing medium is provided, and the method is used for adjusting and controlling the height of a printing medium in a printing device. figure 1 A flow chart showing the method for controlling the height adjustment of printing media according to the present invention. Such as figure 1 As shown, the printing medium height adjustment control method according to the present invention includes:

[0038] Step S11, before starting printing, control the carrying unit carrying the printing medium to run horizontally, and detect the vertical distance between the surface of the printing medium and the end face of the print head whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com