Grouting lifting curve characteristic printing method and system

A printing system and curve technology, applied in the computer field, can solve the problems of inconvenience and cost, and achieve the effect of saving printing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

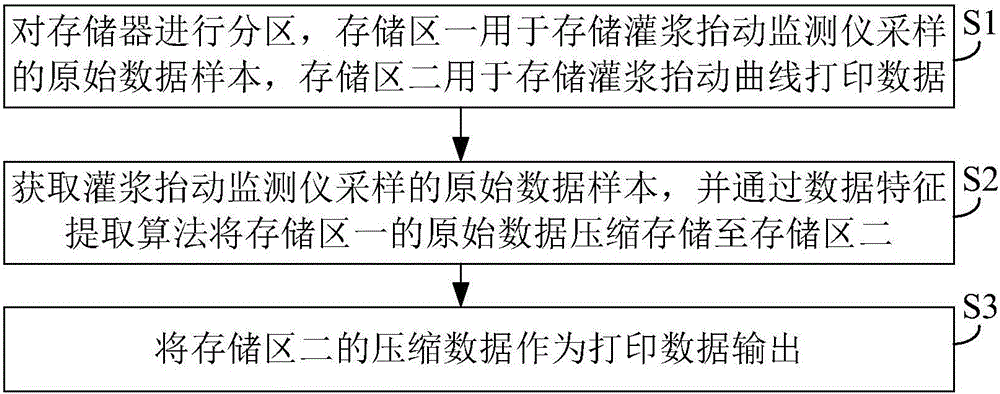

[0020] This embodiment discloses a method for printing grouting lifting curve features, such as figure 1 shown, including:

[0021] Step S1, partitioning the memory, storage area 1 is used to store the original data samples sampled by the grouting lift monitor, and storage area 2 is used to store the printed data of the grouting lift curve.

[0022] Preferably, this step also includes: dividing the storage area 1 and storage area 2 into storage blocks for the following step S2 to store the original data samples and compressed data in the storage area 1 and storage area respectively according to time periods. Corresponding storage block of zone 2.

[0023] Step S2. Obtain the original data samples sampled by the grouting lift monitor, and compress and store the original data in the storage area 1 to the storage area 2 through the data feature extraction algorithm.

[0024] In this step, optionally, the data feature extraction algorithm may use the Ramer-Douglas-Peucker algori...

Embodiment 2

[0033] Corresponding to the above-mentioned embodiment 1, this embodiment discloses a grouting lifting curve feature printing system, which at least includes the following modules 1 to 3:

[0034] Module 1 is used to partition the memory, the storage area 1 is used to store the raw data sample sampled by the grouting lift monitor, and the storage area 2 is used to store the printing data of the grouting lift curve.

[0035] Module 2 is used to obtain the original data samples sampled by the grouting lift monitor, and compress and store the original data in storage area 1 to storage area 2 through the data feature extraction algorithm; optionally, the data feature extraction algorithm can use Ramer- Douglas-Peucker algorithm.

[0036] Module 3 is used to output the compressed data in storage area 2 as print data.

[0037] Preferably, the above-mentioned module 1 is also used to divide the above-mentioned storage area 1 and storage area 2 into storage blocks; the above-mentione...

Embodiment 3

[0042] This embodiment realizes the flow process of above-mentioned embodiment 1 based on Matlab software platform and / or Delphi software platform with computer, and concrete parameterization, framework and flow process thereof of relevant system can refer to above-mentioned embodiment 1 and 2, in this embodiment I won't go into details.

[0043] Specifically: the grating sensor or capacitive sensor can transmit data to the 232 interface, and the format of each measurement of lifting displacement is #02315. #Indicates the starting character of a displacement value, the displacement value is represented by a five-digit BCD code, if the high digit is insufficient, it is represented by 0, 02315 represents the displacement of 2315 microns, if the next data is #12315, it represents the displacement of the displacement is 12315 microns. After the computer uses the serial port reading control SSCOM to receive the serial port data. The baud rate of the computer serial port communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com