A rotary adjustable fused deposition printing support device

A technology of fused deposition and support devices, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., to achieve the effect of improving printing efficiency, simple structure, and reducing printing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described in detail below in conjunction with the drawings and embodiments.

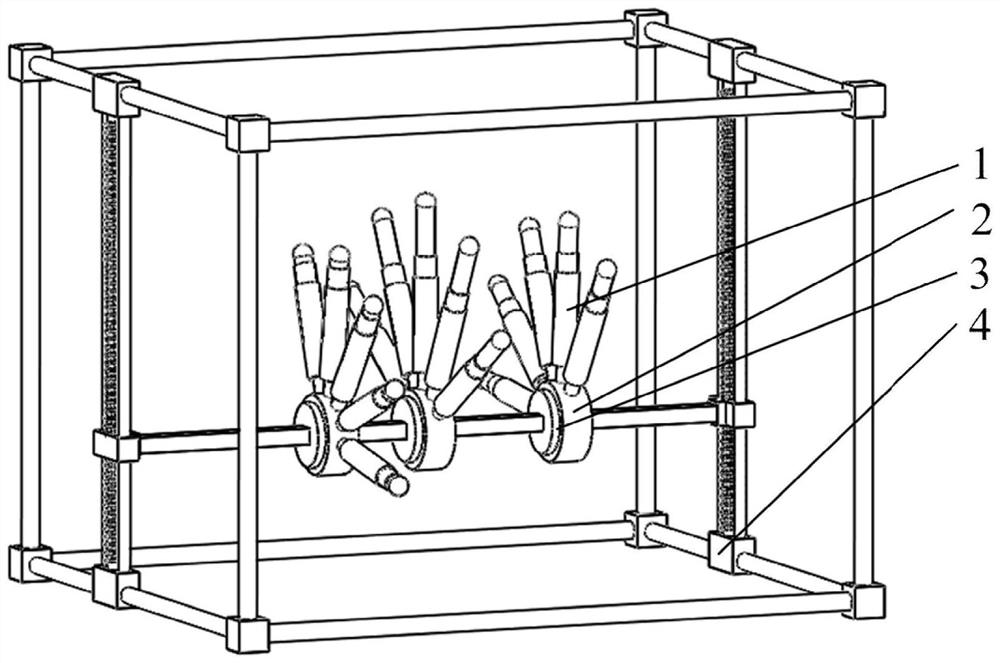

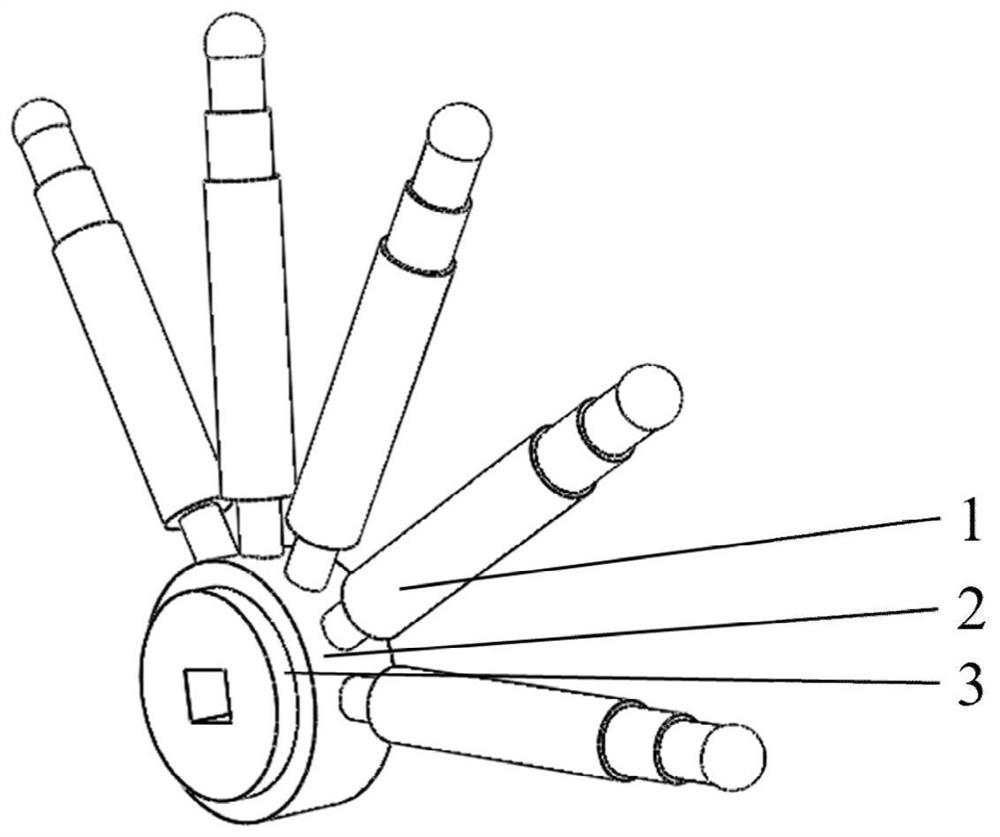

[0031]Such asfigure 1 As shown, the specific implementation of the device moving device, support device, support rod and support motion control module; the support device 2 is installed on the mobile device 4; multiple support rods 1 are inserted on the support device 2 and moved to the support position to support The physical model to be printed; the support motion control module is respectively connected to the support device 2 and the support rod 1, and is used to control the movement of the support device 2 and the support rod 1, so that the support rod 1 is deployed on the support device 2 and the support device 2 moves Go to the position on the mobile device 4 to support the physical solid model to be printed.

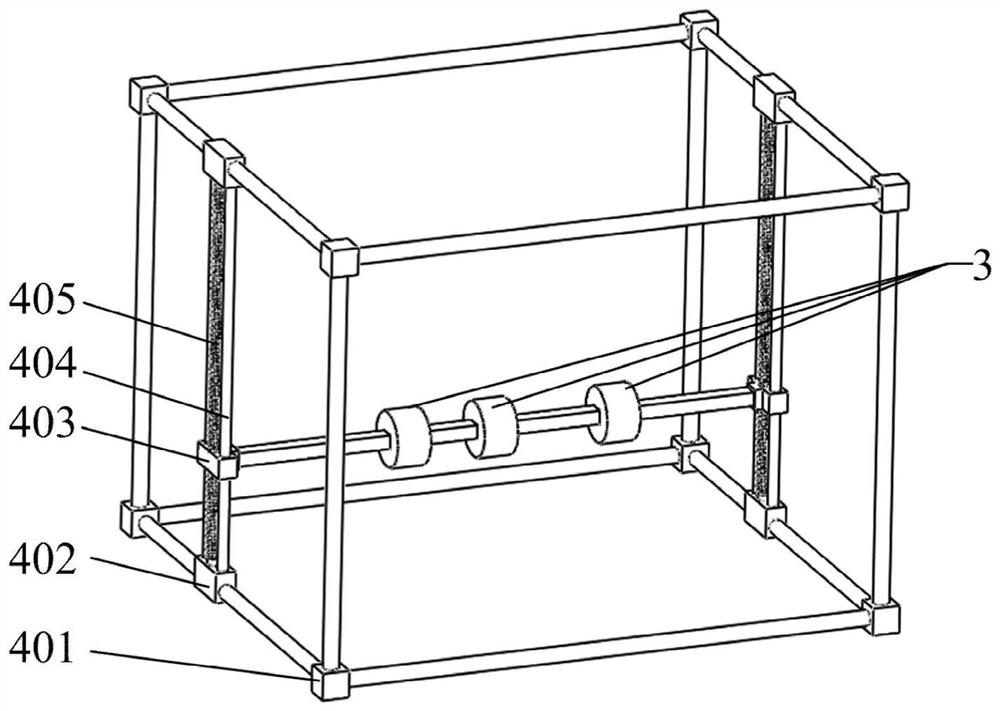

[0032]Such asimage 3 As shown, the moving device 4 is a three-dimensional moving mechanism, which specifically includes a frame 401, a z-axis moving slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com