A fully automatic printing water purification machine

A fully automatic, water purification technology, applied in multi-stage water treatment, non-polluting water treatment, water/sewage treatment, etc., can solve the problems of inability to process other substances, inability to purify, unstable water quality, etc., to save printing consumables , The printing quality is stable, and the effect of ensuring the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

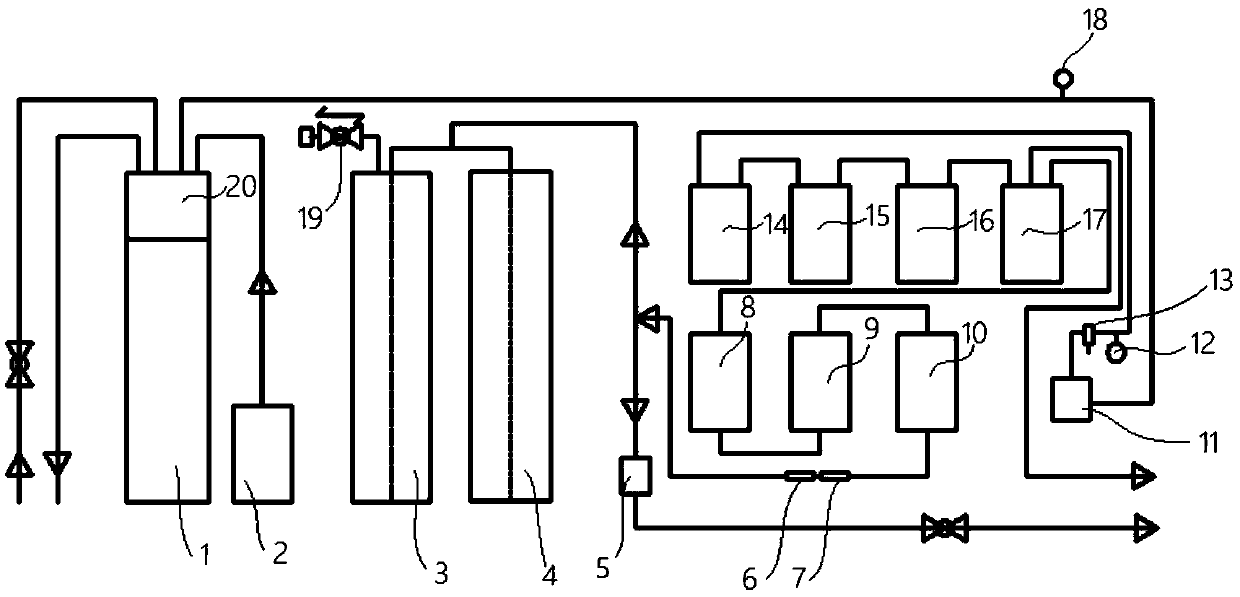

[0023] See figure 1 .

[0024] A fully automatic printing water purification machine, including water softening part, purification part, back pressure storage part and automatic constant pressure water supply part:

[0025] The water softening part includes a resin softener 1, an automatic water softening controller 20, and a salt tank 2 connected to the automatic water softening controller 20. The water inlet of the automatic water softening controller 20 is connected to the tap water outlet, and the water outlet is connected to the water inlet of the purification part. The water softening automatic controller 20 is provided with a drainage outlet;

[0026] The purification part includes a filter device and a purification device. The water inlet of the filter device is connected to the water softening part outlet, the water outlet of the filter device is connected to the water inlet of the purification device, and the water outlet of the purification device is connected to t...

Embodiment 2

[0031] In this embodiment, the filter device includes a PP cotton filter 14, an activated carbon filter 15, a precision pp cotton filter 16, and an RO filter 17 connected in series in sequence: the water softened by the resin enters the PP cotton filter 14, activated carbon filter Device 15, precision pp cotton filter 16, RO filter 17 to achieve high-precision filtration. All the other technical solutions are consistent with embodiment 1. Multi-stage filtration improves filtration accuracy.

Embodiment 3

[0033] In this embodiment, the waste water outlet is set on the RO filter 17, and the waste water is discharged in a ratio of 3:1. All the other technical solutions are consistent with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com