Hollow knife handle with spindle direct-connection transmission mode adopting ultralow-temperature medium

An ultra-low temperature, tool holder technology, used in milling cutters, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of poor sealing performance, inability to be suitable for ultra-low temperature medium hollow transmission, etc., to reduce the vaporization rate, facilitate disassembly, The effect of eliminating the influence of fit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

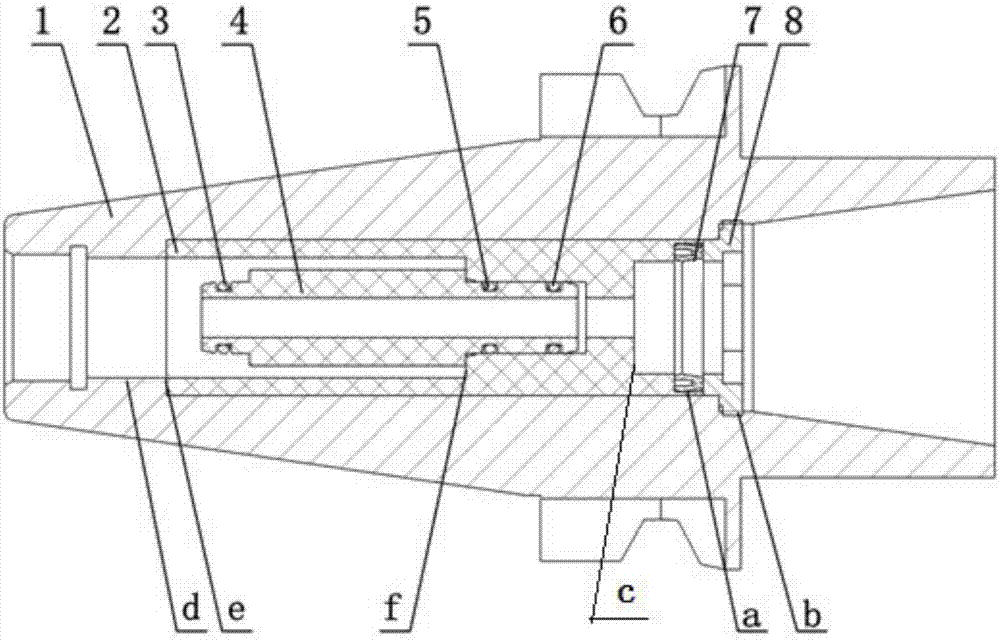

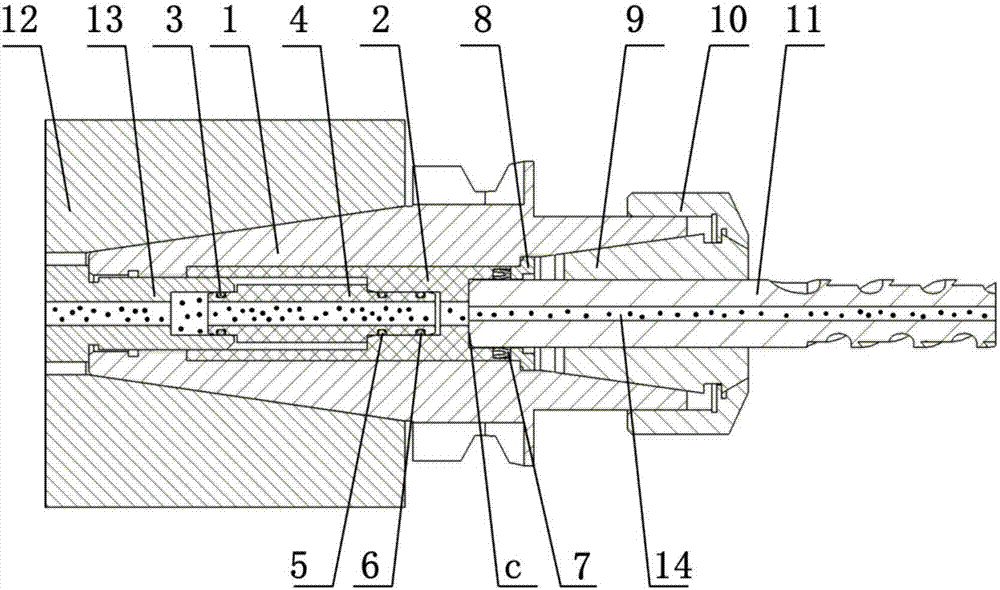

[0011] In the embodiment, the ultra-low temperature medium is liquid nitrogen, the heat insulation sleeve 2 and the pipe 4 are made of low temperature resistant, low thermal conductivity materials, and the thermal conductivity of the structural materials of the heat insulation sleeve 2, the pipe 4 is less than 0.23W / (m· K). The connection structure between the tool holder and the spindle is designed according to the BT standard, the 7:24 taper accuracy is AT3, and the hardness is above HRC55. In the multi-level sealing structure, the three left, middle and right O-rings 3, 5, 6 and the pan plug seal 7 are all low-temperature resistant sealing rings, forming a multi-level ultra-low temperature seal, and can withstand a pressure of about 2MPa, achieving ultra-low temperature Radial seal of the medium.

[0012] The hollow tool holder is designed and assembled as figure 1 Shown. First, install the heat insulation sleeve 2 from the right end of the tool holder body 1; put the pan pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com