Method and device for improving the grade of copper-selected copper

A technology of grade, rough concentrate, applied in flotation, solid separation and other directions, can solve the problems of prolonged flotation time, waste of chemicals, fluctuation of liquid level in selected operation, etc. Small and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

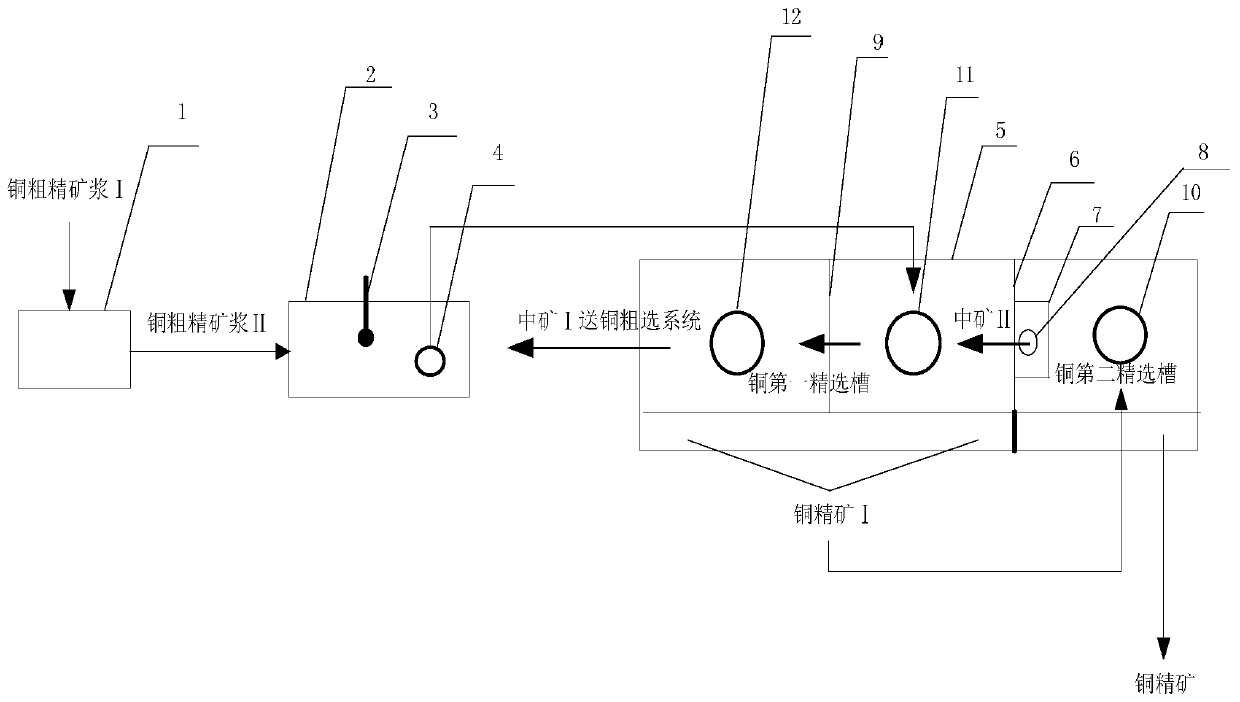

Image

Examples

Embodiment 1

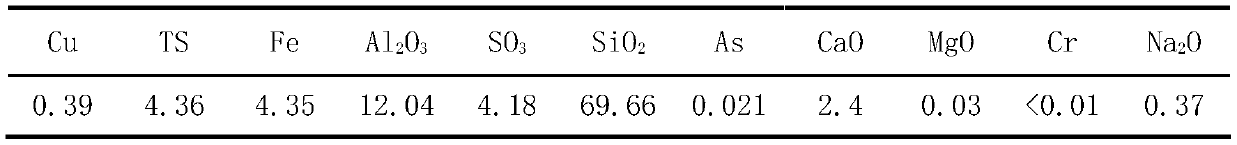

[0051] Taking a copper mine flotation plant in Fujian as an example, the main metal minerals are pyrite, blue chalcocite, copper blue, chalcocite, and trace amounts of bornite, chalcopyrite, tetrahedrite, Sulfur tin iron copper ore, sulfur bismuth copper ore, natural gold, etc.; non-metallic minerals are mainly quartz, dickite, alunite and a small amount of iron oxide, sericite, chlorite, etc. The results of multi-element analysis of the raw ore are shown in Table 1.

[0052] Table 1 Results of multi-element analysis of raw ore

[0053]

[0054] A method for improving the grade of copper-selected copper, comprising the following sequential steps and conditions:

[0055] The first step: add water to control the mass concentration of the copper rough concentrate to 25% by adding water to the copper rough concentrate slurry I obtained by the copper roughing operation of the copper-containing ore, and at the same time add water glass as a regulator at a rate of 100g / t. Add re...

Embodiment 2

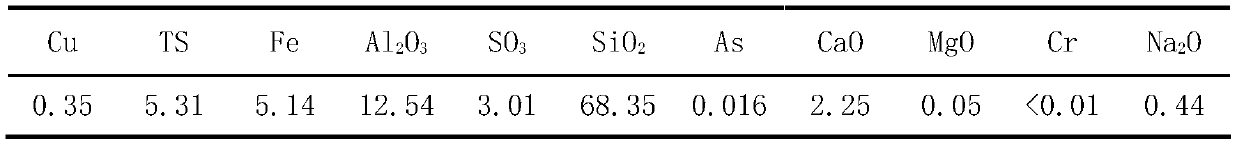

[0061] A copper-sulfur ore in Anhui Province, the main metal minerals are pyrite, pyrrhotite, blue chalcocite, chalcocite, and a small amount of chalcopyrite, tetrahedrite, pyrotite, sulfur bismuth Copper ore, natural gold, etc.; non-metallic minerals are mainly quartz, a small amount of alunite, dickite, iron oxide, sericite, chlorite, etc. The results of multi-element analysis of the raw ore are shown in Table 2.

[0062] Table 2 Results of multi-element analysis of raw ore

[0063]

[0064] A method for improving the grade of copper-selected copper, comprising the following sequential steps and conditions:

[0065] The first step: add water to control the mass concentration of the copper coarse concentrate to 24% by adding water to the copper coarse concentrate slurry I obtained by the copper roughing operation of the copper-containing ore, and at the same time add the regulator water glass at 80g / t, press Add regulator sodium hexametaphosphate at 30g / t and add regulat...

Embodiment 3

[0071] Taking a copper mine flotation plant in Jilin as an example, the main metal minerals are pyrite, blue chalcocite, copper blue, tetrahedrite, and there are trace amounts of chalcopyrite, natural gold and silver, etc.; non-metallic minerals are mainly It is quartz, followed by calcite, dolomite, sericite, plagioclase, potassium feldspar, chlorite, a small amount of apatite, dickite, alunite, etc. The results of multi-element analysis of the raw ore are shown in Table 3.

[0072] Table 3 Results of multi-element analysis of raw ore

[0073]

[0074] A method for improving the grade of copper-selected copper, comprising the following sequential steps and conditions:

[0075] The first step: add water to control the mass concentration of the copper rough concentrate to 26% by adding water to the copper rough concentrate slurry I obtained by the copper roughing operation of the copper-containing ore, and add water glass as a regulator at 200g / t at the same time. Add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com