DC-DC resonance converter

A resonant converter, DC-DC technology, applied in the direction of converting DC power input to DC power output, instruments, adjusting electrical variables, etc., can solve the problems of large volume, high conduction voltage drop, increase loss, etc., and achieve technical difficulties Low, small number of devices, the effect of increasing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

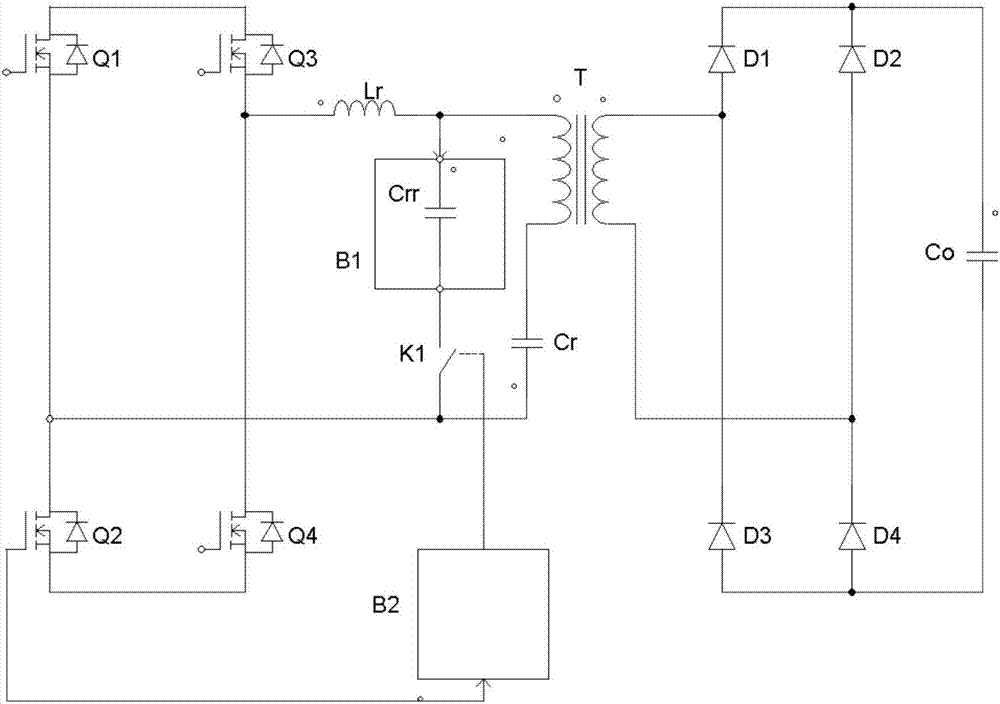

[0043] like image 3 As shown, a DC-DC resonant converter includes: full bridge switching circuit (power tube Q1, power tube Q2, power tube Q3, power tube Q4), resonant circuit (resonant inductor Lr, resonant capacitor Cr, parallel network B1 ), a transformer (T) and an output rectification filter circuit (rectifier diode D1, rectifier diode D2, rectifier diode D3, rectifier diode D4, capacitor Co).

[0044] Capacitor Crr and switch K1 are connected in series to form the first branch, and transformer T and resonant capacitor Cr are connected in series to form the second branch. After the first branch and the second branch are connected in parallel, one end is connected to the output end of the full-bridge switching circuit through the resonant inductor Lr. After the first branch and the second branch are connected in parallel, the other end is connected to the other end of the output of the full bridge switch circuit, the secondary side of the transformer T is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com