Heat treatment method for improving mechanical property of austenitic heat-resistance steel

A technology of austenitic heat-resistant steel and heat treatment method, applied in the field of heat treatment, can solve the problems of limited improvement of mechanical properties and achieve the effect of performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

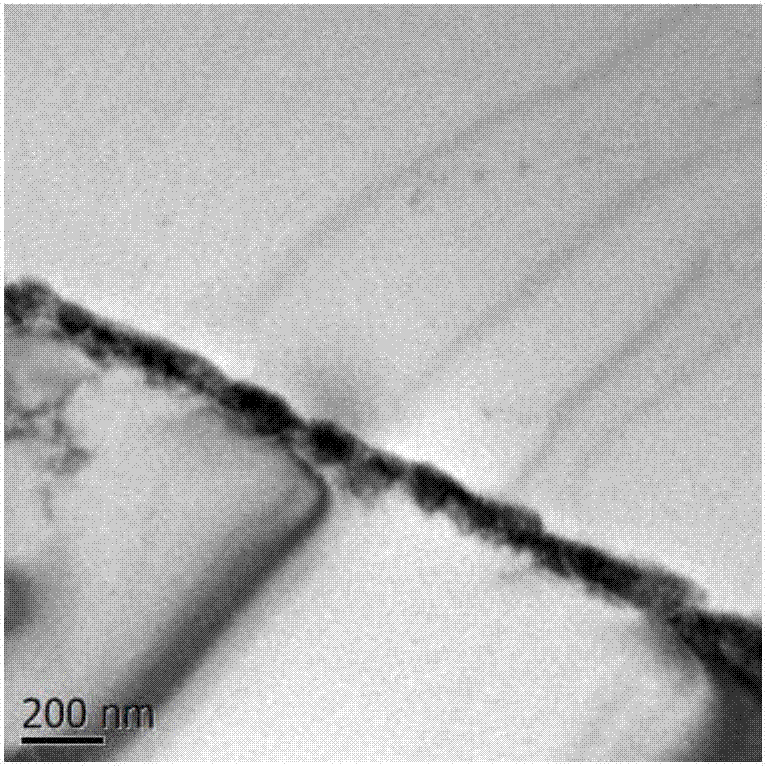

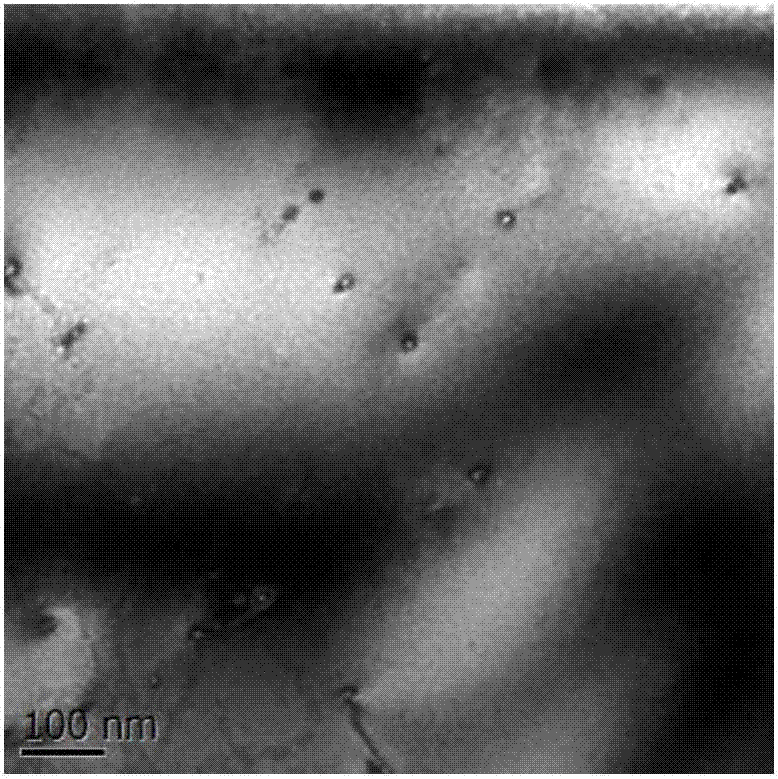

[0025] The invention discloses a heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, which uses a solution treatment process combined with a medium-temperature short-term aging treatment to precipitate fine M 23 C 6 phase and nano-sized Z phase (NbCrN phase) to optimize the performance of heat-resistant steel. The comparison between the chemical composition of the austenitic heat-resistant steel obtained in this example and the existing HR3C steel is shown in Table 1.

[0026] Table 1 Chemical composition (mass %, balance is Fe) of austenitic heat-resistant steel (1#) and comparative example (HR3C steel) used in Example 1.

[0027]

[0028] The present invention is a heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, the steps are as follows:

[0029] 1. Heat the alloy sample that has been homogenized and thermally deformed in sequence to 1230°C, keep it warm for 30 minutes for so...

example 2

[0040] A heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, comprising the steps of,

[0041] Step 1. Raw materials are prepared according to the alloy composition and burning loss, and the raw materials are melted and cast into alloy ingots in a vacuum environment;

[0042] Step 2, the alloy ingot is subjected to homogenization and thermal deformation treatment in sequence;

[0043] Step 3, performing solution heat treatment on the hot-deformed alloy at 1200°C for 45 minutes, and then water-cooling to room temperature;

[0044] Step 4, short-term aging treatment at medium temperature: heat the alloy after solution heat treatment to 800°C, hold it for 30 minutes, and cool it to room temperature in air. get M 23 C 6 Mutually.

[0045] In this preferred example, the alloy ingot is homogenized at 1150° C. for 30 hours. The homogenized alloy ingot is subjected to heat deformation treatment at 1150°C.

example 3

[0047] A heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, comprising the steps of,

[0048] Step 1. Raw materials are prepared according to the alloy composition and burning loss, and the raw materials are melted and cast into alloy ingots in a vacuum environment;

[0049] Step 2, the alloy ingot is subjected to homogenization and thermal deformation treatment in sequence;

[0050] Step 3, performing solution heat treatment on the hot-deformed alloy at 1260° C. for 35 minutes, and then water-cooling to room temperature;

[0051] Step 4, short-term aging treatment at medium temperature: heat the alloy after solution heat treatment to 760°C, hold it for 40 minutes, and cool it to room temperature in air. get M 23 C 6 Mutually.

[0052] In this preferred example, the alloy ingot is homogenized at 1200° C. for 20 hours. The homogenized alloy ingot is subjected to heat deformation treatment at 1150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com