A method and device for producing 1,3-propanediol by microbial transformation

A technology for microbial transformation and propylene glycol, applied in the field of bioengineering, can solve the problems of increasing by-products, unable to effectively reduce the generation of by-products, etc., and achieve the effects of improving the conversion rate, facilitating the stable period of fermentation, and improving the level of fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

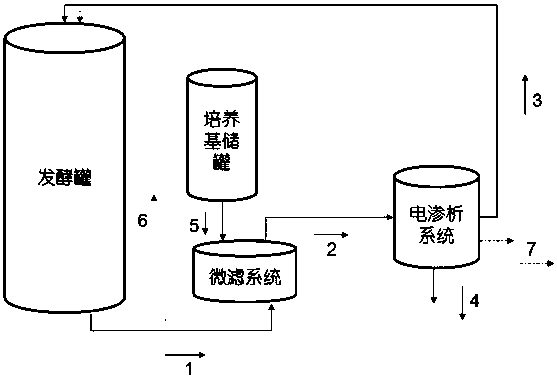

Image

Examples

Embodiment 1

[0033] (1) Take the liquid preserved Klebsiella ( Klebsieblla pneumoniae ) 5mL of strain preservation solution was added to a 3L primary seed tank containing 2.5L of seed medium for strain activation and cultivation. After 24 hours of culture, the dry weight of the cells reached 2.5g / L, and they were transferred to a secondary seed tank containing 22.5L of medium for strain expansion. After culturing for 18 hours, the dry weight of the cells reached 2.6 g / L, and the culturing was terminated, and the obtained seed solution was inoculated into a fermenter. Culture conditions: the nitrogen gas flow rate is 0.1vvm, the stirring speed is 300rpm, the culture temperature is 37°C, and the pH is adjusted to 7 with 5M NaOH.

[0034] (2) Pass the seed liquid obtained in step (1) through the pipeline, and press sterile nitrogen into the fermenter containing 225L of fermentation medium. Nitrogen was introduced during the fermentation process to maintain the anaerobic environment. The am...

Embodiment 2

[0043] (1) Take the liquid preserved Klebsiella ( Klebsieblla pneumoniae ) 25mL of strain preservation solution was added to a 3L primary seed tank containing 2.5L of seed medium for strain activation and cultivation. After culturing for 18 hours, the dry weight of the cells reached 2.0 g / L, and they were transferred to a secondary seed tank containing 22.5 L of medium for strain expansion. After culturing for 18 hours, the dry weight of the cells reached 2.5 g / L, and the culturing was terminated, and the obtained seed solution was inoculated into a fermenter. Culture conditions: the nitrogen ventilation rate is 0.1vvm, the stirring speed is 200rpm, the culture temperature is 37°C, and the pH is adjusted to 6.5 with 5M NaOH.

[0044] (2) Pass the seed liquid obtained in step (1) through the pipeline, and press sterile nitrogen into the fermenter containing 225L of fermentation medium. Nitrogen was introduced during the fermentation process to maintain the anaerobic environm...

Embodiment 3

[0052] (1) Take the liquid preserved Klebsiella ( Klebsieblla pneumoniae ) 15mL of strain preservation solution was added to a 3L primary seed tank containing 2.5L of seed medium for strain activation and cultivation. After 24 hours of culture, the dry weight of the cells reached 3.2g / L, and they were transferred to a secondary seed tank containing 22.5L of medium for strain expansion. After culturing for 18 hours, the dry weight of the cells reached 3.0 g / L, and the culturing was terminated, and the obtained seed solution was inoculated into a fermenter. Culture conditions: the nitrogen gas flow rate is 0.1vvm, the stirring speed is 200rpm, the culture temperature is 37°C, and the pH is adjusted to 6.8 with 5M NaOH.

[0053](2) Pass the seed liquid obtained in step (1) through the pipeline, and press sterile nitrogen into the fermenter containing 225L of fermentation medium. Nitrogen was introduced during the fermentation process to maintain the anaerobic environment. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com