Energy-saving production method and device for carbon black through off-line preheating of process air

A production device, carbon black technology, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of increased load on the rear collection system, increased thermal stress of the air preheater, increased equipment, and civil engineering Cost and other issues, to achieve the effect of economy and long-term operation, comprehensive energy consumption reduction, and product cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

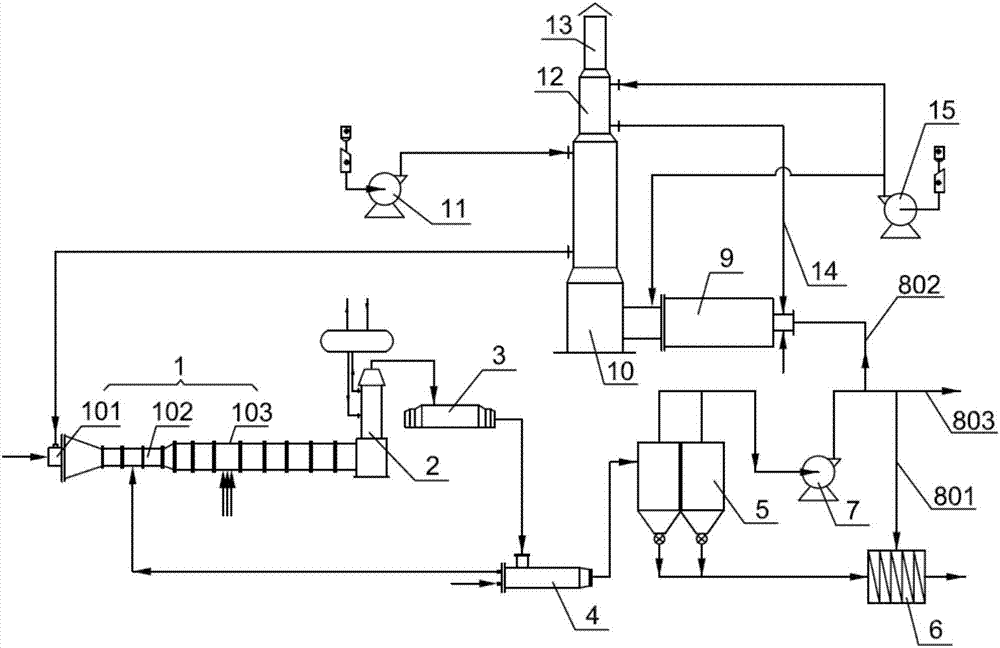

[0023] The present invention will be further described below in conjunction with accompanying drawing:

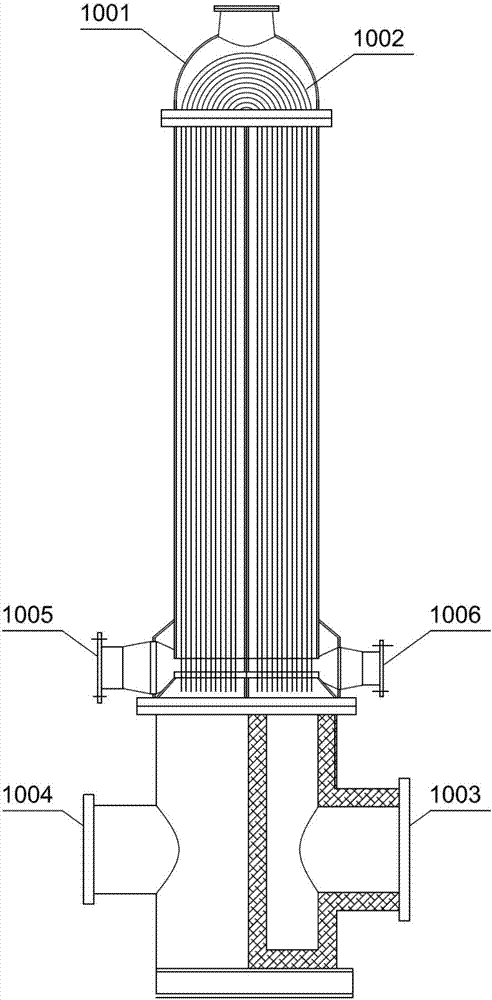

[0024] Refer to attached figure 1 And attached figure 2 , the present invention provides a carbon black energy-saving production method and device for off-line preheating process air, and the carbon black energy-saving production method of off-line preheating process air of the present invention comprises the following steps,

[0025] a. The reaction furnace flue gas produced by the reaction of carbon black reaction furnace 1 is passed into the high gradient quenching heat exchanger 2, waste heat boiler 3, and raw material oil preheater 4 in turn, and then sent to the main bag filter 5; the reaction furnace flue gas passes through the main bag Filter 5 separates carbon black and tail gas;

[0026] B, carbon black is introduced into carbon black aftertreatment device 6;

[0027] c. The tail gas is divided into A, B, and C stocks; the tail gas of the A stock is introduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com