Method for preparing polyether amine through direct amination of polyether polyol

A technology of polyether alcohol and polyether amine, which is applied in the field of preparation or chemical processing of organic polymer compounds, can solve the problems of high energy consumption and equipment cost, unfavorable switching production of polyether amine, and great influence on the catalytic activity of catalysts, etc. Achieve the effects of low investment in process equipment, convenient product switching, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

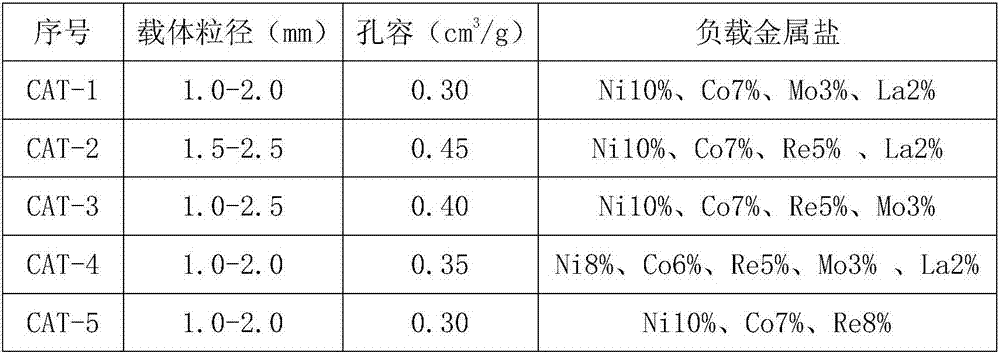

[0025] Embodiment 1: the composition of different catalysts

[0026] γ-Al 2 o 3 As a carrier, any three or more combinations of metal nickel 5-15%, cobalt 5-10%, rhenium 2-10%, molybdenum 1-5%, and lanthanum 1-5% are loaded. 1.

[0027] Table 1 Different catalyst composition

[0028]

[0029]

[0030] We also tested the amount of catalyst added: CAT-4 was used as the catalyst, PPG-5000 was selected as the polyether, polyether: liquid ammonia (mol) = 1:5; the hydrogen pressure was 1.0MPa, and the reaction temperature was 180°C. The reaction pressure is 10MPa, and the holding time is 4 hours; the diameter of the stirring paddle of the reactor is 2 / 3 of the internal diameter of the kettle, the inclination angle of the propulsion type stirring paddle is 45°, the bottom end is a propulsion type paddle, and the height of 2 / 3 It is a turbine-type stirring paddle, and the addition amount of the catalyst is also tested under the same conditions, and the results show that when...

Embodiment 2

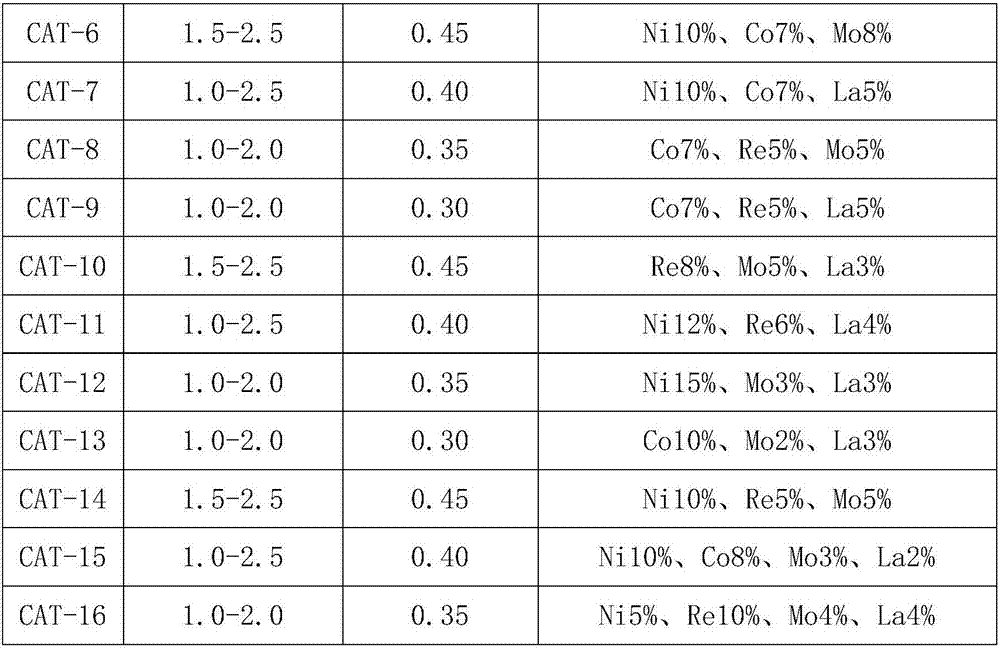

[0031] Embodiment 2: the reaction effect of different catalysts

[0032] The catalyst prepared in Example 1 was added into a high-pressure reactor, wherein the stirring blade of the reactor was a combined stirring blade. The bottom end is a push-type stirring paddle, the inclination angle of the push-type stirring paddle is 45°, the diameter is 2 / 3 of the internal diameter of the kettle, and the 2 / 3 height is a turbine-type stirring paddle. Add polyether, liquid ammonia and hydrogen to the reactor in sequence. Slowly raise the temperature to the required temperature and keep it warm for a certain period of time, turn off the heating power supply, and turn on the cooling water to cool down and discharge the material.

[0033] The reaction effect of different catalysts in table 2

[0034]

[0035]

[0036] Test 1: The amount of catalyst added is 10% of the whole system, the reaction temperature is 180°C, the reaction pressure is 10MPa, the holding time is 5 hours, and th...

Embodiment 4

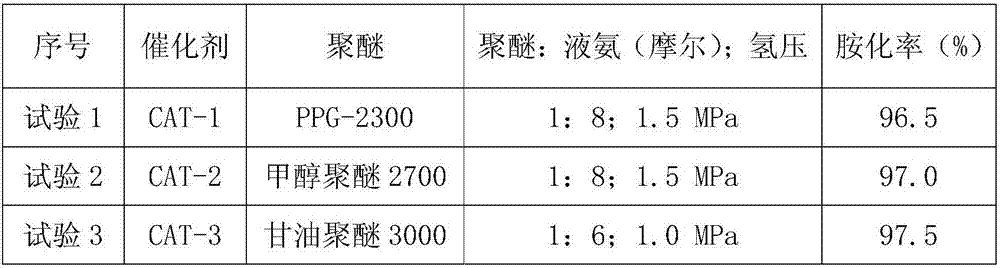

[0058] Embodiment 4: the influence of different amination conditions on the finished product effect

[0059] In this embodiment, CAT-4 is used as the catalyst, the amount of catalyst added is 10% of the whole system, and the polyether is selected from PPG-5000; the diameter of the stirring paddle of the reactor is 2 / 3 of the internal diameter of the kettle, and the The inclination angle is 45°, the bottom end is a propulsion type stirring paddle, and the 2 / 3 height is a turbine type stirring paddle. During the reaction, the water content is lower than 1%. Different synthesis conditions are tested, as shown in Table 4.

[0060] The influence of table 4 different amination conditions on synthetic effect

[0061]

[0062]

[0063] (1) Effect of addition ratio: Under the same conditions, the polyether: liquid ammonia molar ratio was tested separately for three grades of lower than 1:5, 1:5-15, and higher than 1:15, see Table 4 for details The serial numbers 1-14. As can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com