Filter and filtering device employing same

A filter device and filter technology, which are applied in the directions of fixed filter element filters, filtration and separation, chemical instruments and methods, etc., to achieve the effects of simple device, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

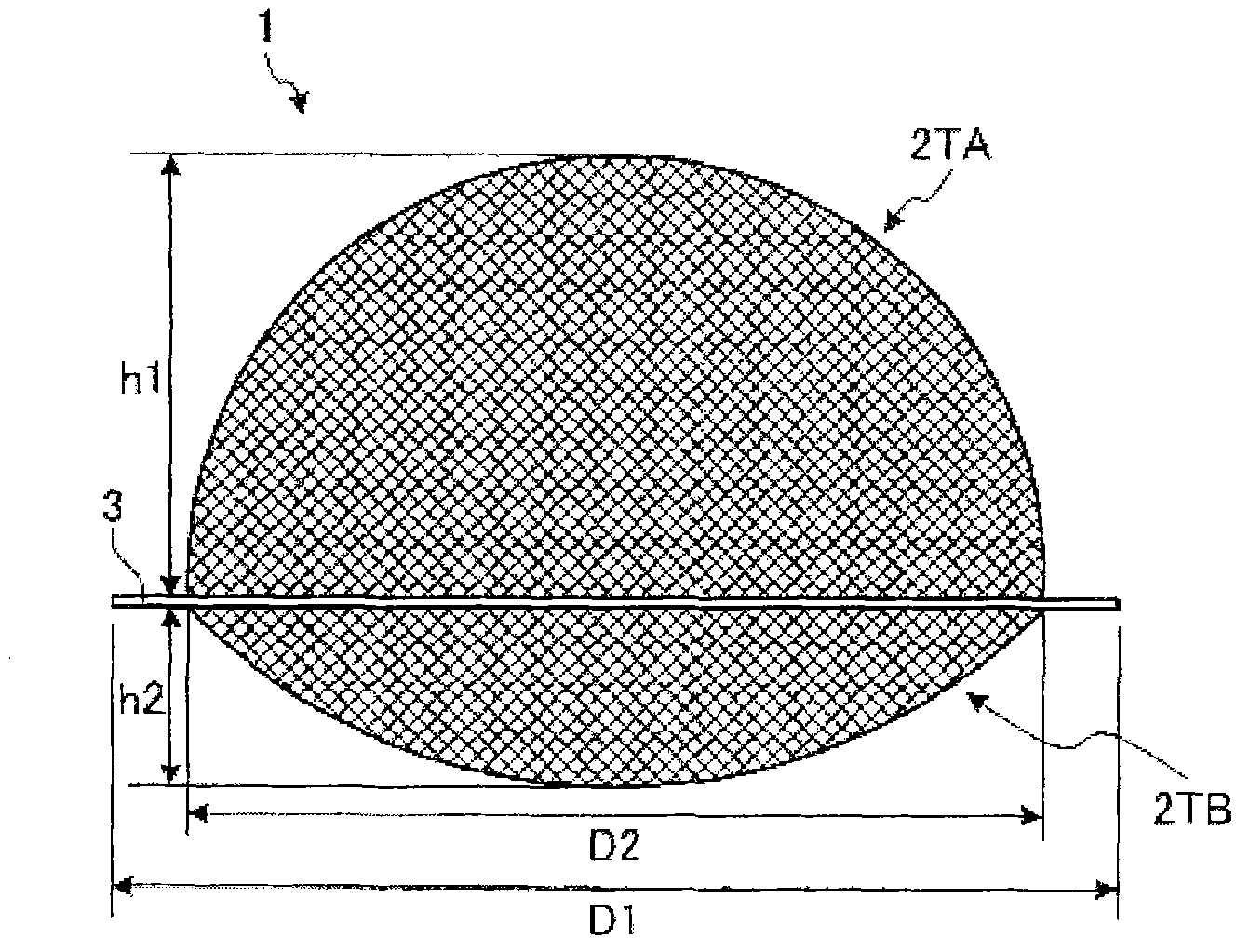

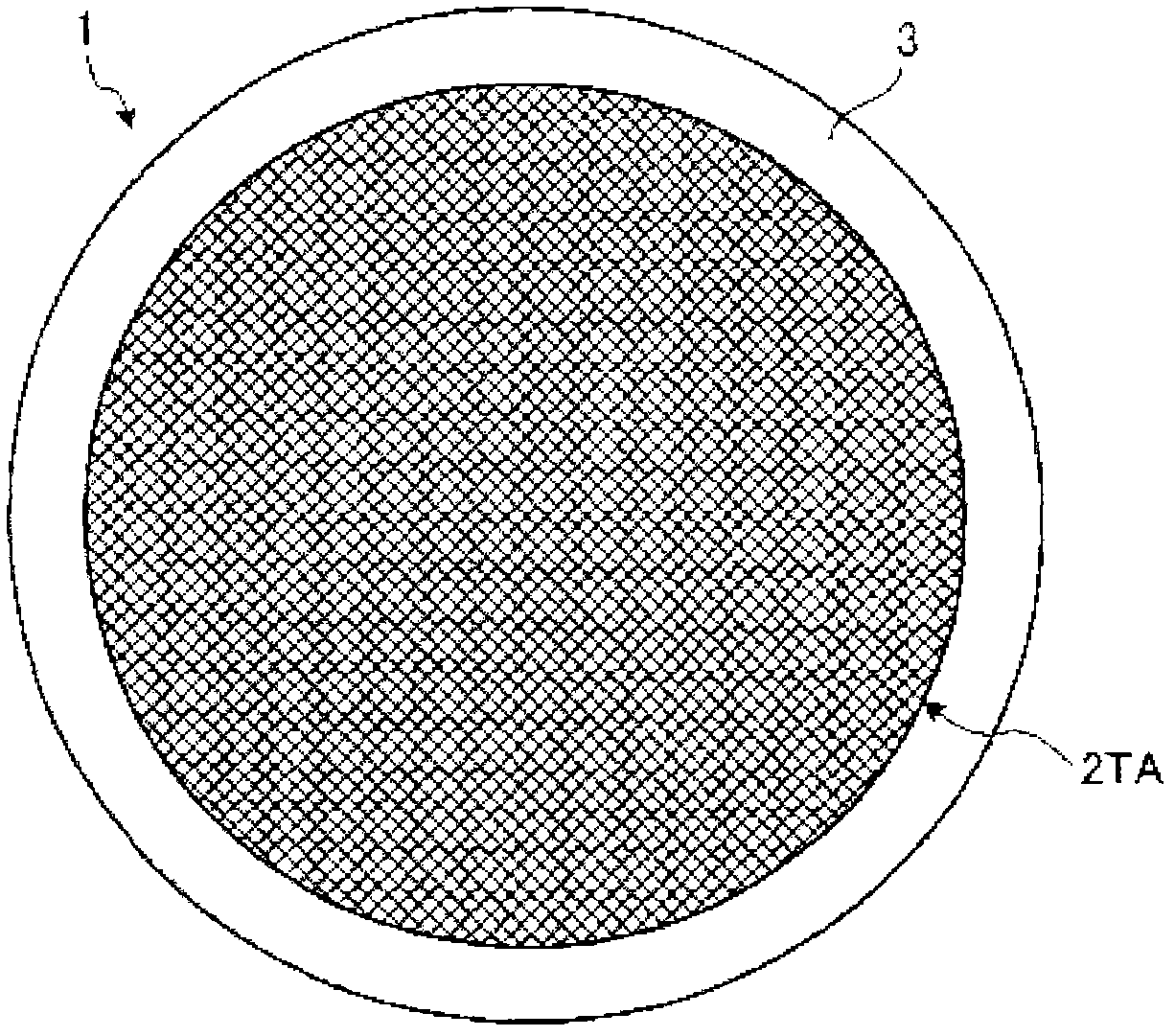

[0104] figure 1 It is a perspective view which shows an example of the filter of Example 1 of this invention. figure 2 It is a front view which shows an example of the filter of Example 1 of this invention. image 3 It is a plan view showing an example of the filter of Example 1 of the present invention. Figure 4 It is a plan view of a cut piece included in the filter of Example 1 of the present invention. Figure 5 yes Figure 4 A-A cutaway view. Figure 6 It is an explanatory diagram of a circular mold used to manufacture the filter of Example 1 of the present invention. Figure 1 ~ Figure 3 An example of the filter of the present invention is shown. The filter 1 uses a predetermined amount of cut pieces (belt-shaped filter plates) 2, and utilizes Figure 6 The shown circular die 4 performs punching to bond and integrate only the peripheral portion 3 to form a filter of a specified size, wherein the cut piece 1 is a plate material disclosed in Patent Document 1 or a ...

Embodiment 2

[0137] Figure 12 It is an external view of the filter device of Example 2, (a) is a front view, (b) is a front view, (c) is a top view of a state with a frame removed, and (d) is a top view of a panel part. Figure 13 It is an explanatory diagram of the action of the filter device of Example 2. Embodiment 1 described above is a batch type that filters the leftover oil after frying food in the fryer for a specified time through the filter device 10 to remove tiny impurities and moisture, etc., and then returns it to the fryer for reuse. Filtration treatment device. In the present invention, the oil in the fryer is sucked by the pump and introduced into the filtering device of the present invention, and after being filtered in the device, the oil is returned to the fryer in a circular filtering manner. Although the structure of the filter device 10 of this embodiment can be substantially the same as that of the filter device 10 of Example 1, since the oil in the fryer is dire...

Embodiment 3

[0144] Figure 14 It is a cross-sectional view of a filter case provided with a filter cover according to Example 3. Figure 15 is a sectional view of the filter cover. Figure 16 It is a perspective view of the support body which a filter cover has. Embodiment 3 is characterized in that the filter 1 in the filter case 11 is covered by the filter cover 61 having a hole through which a filter object (edible oil in this embodiment) passes. Filter housing 11 and the filtering device 10 of embodiment 1 (referring to Figure 8 ) with the filter housing 11 (refer to Figure 7 )same.

[0145] The filter 1 in the filter case 11 is covered with a cylindrical filter cover 61 . A filter cover retainer 63 is provided on a portion of the cover member 23 facing the filter cover 61 . A filter housing presser 63 may also be provided on the filter housing 61 . The end surface 62 on the opening side of the filter cover 61 is in contact with the peripheral portion 3 of the filter 1 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com