Ultrasonic coating liquid temperature control device and method

A temperature control device and ultrasonic technology, which are applied in the device, separation method, chemical instrument and method for coating liquid on the surface, etc. Low requirements and other problems, to achieve the effect of eliminating agglomerates or bubbles and stabilizing the temperature of the coating liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

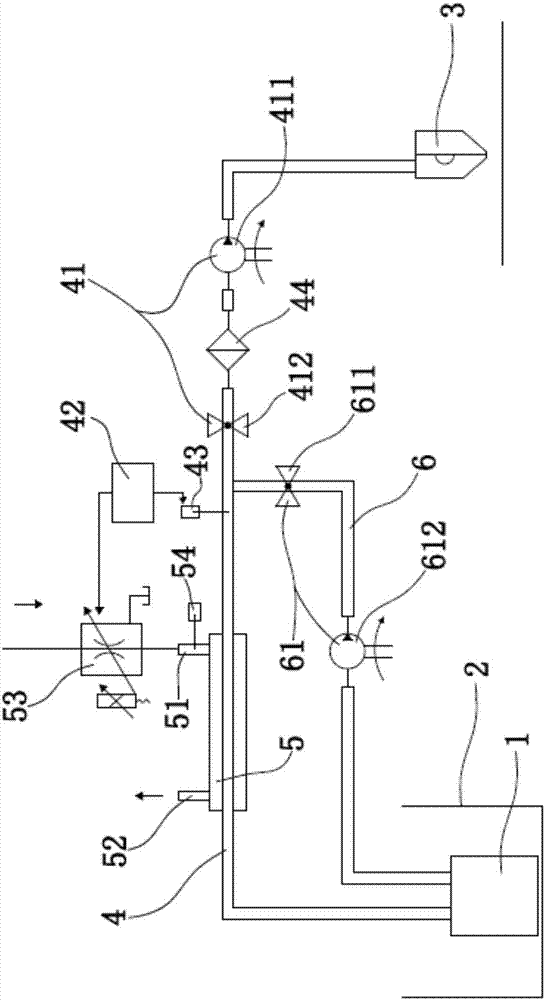

[0039] In order to achieve the purpose of the present invention, as figure 1 As shown, in some embodiments of an ultrasonic coating liquid temperature control device of the present invention, it includes: a liquid storage part 1, which is fixedly arranged in the ultrasonic part 2; a coating head 3, which passes through the liquid supply pipe The road 4 is connected to the liquid storage part 1, the first liquid pump assembly 41 is installed on the liquid supply pipeline 4; the water bath temperature control part 5 is fixedly arranged on the liquid supply pipeline 4, and the water bath temperature control part 5 is also provided with an inlet The water pipeline 51 and the water outlet pipeline 52, the proportional flow valve 53 is also installed on the water inlet pipeline 51, the water bath temperature control part 5 is used to monitor the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com