Apparatus for preventing tube mill material from being agglomerated

A tube mill and material technology, applied in grain processing, etc., can solve the problems of high energy consumption and low grinding efficiency in the fine grinding chamber of the tube mill, so as to reduce the energy consumption of the mill, improve the interaction between the grinding body and the material, and reduce the energy consumption of the mill. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

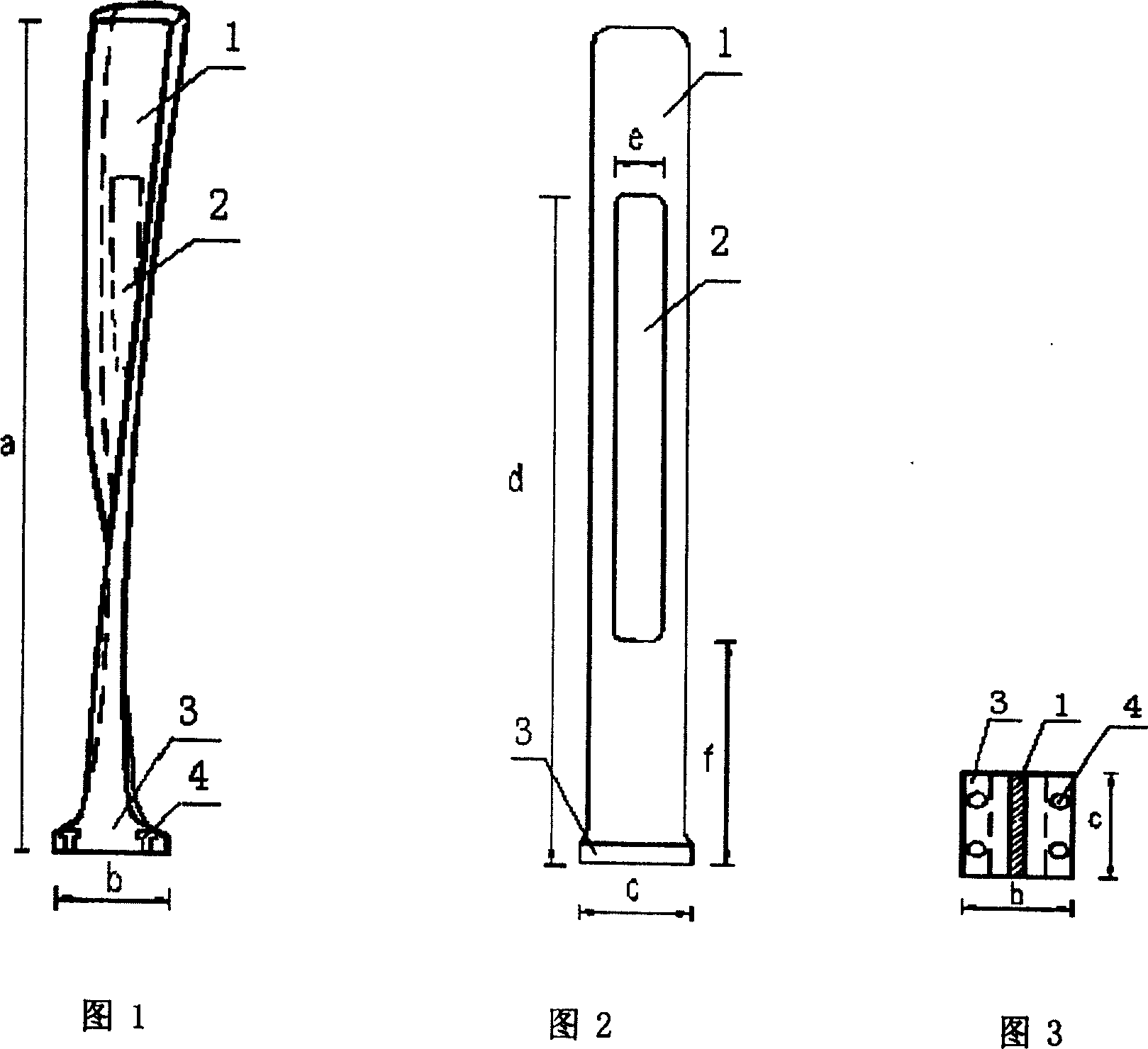

[0020] As shown in Figure 1, Figure 2, and Figure 3, a device for preventing material agglomeration in a tube mill (referred to as an anti-agglomeration device), which is composed of a stirring plate 1 and a base 3, is an integral structure, and is made of ordinary alloy steel Processed, the stirring plate 1 is twisted, the middle part of the stirring plate 1 is provided with a hole 2, the base 3 is located at the bottom of the stirring plate 1, and the base 3 is provided with a fixing hole 4.

[0021] The stirring plate 1 and the base 3 can be two separate parts, and the bottom of the stirring plate 1 is welded to the base 3 .

[0022] The sum of the heights of stirring plate 1 and base 3 is 0.5m, the width of base 3 is 0.1m, the length of base 3 is 0.15m, and the distance from the top of hole 2 to the bottom of base 3 is d. 0.4m, the width e of the hole 2 is 0.07m, and the distance f from the bottom end of the hole 2 to the bottom end of the base 3 is 0.1m.

[0023] As show...

Embodiment 2

[0026] As shown in Figure 1, Figure 2, and Figure 3, a device for preventing material agglomeration in a tube mill (referred to as an anti-agglomeration device), which is composed of a stirring plate 1 and a base 3, is an integral structure, and is made of ordinary alloy steel Processed, the stirring plate 1 is twisted, the middle part of the stirring plate 1 is provided with a hole 2, the base 3 is located at the bottom of the stirring plate 1, and the base 3 is provided with a fixing hole 4.

[0027] The sum of the heights of stirring plate 1 and base 3 is 0.6m, the width of base 3 is 0.12m, the length of base 3 is 0.2m, and the distance from the top of hole 2 to the bottom of base 3 is d. 0.45m, the width e of the hole 2 is 0.1m, and the distance f from the bottom end of the hole 2 to the bottom end of the base 3 is 0.15m.

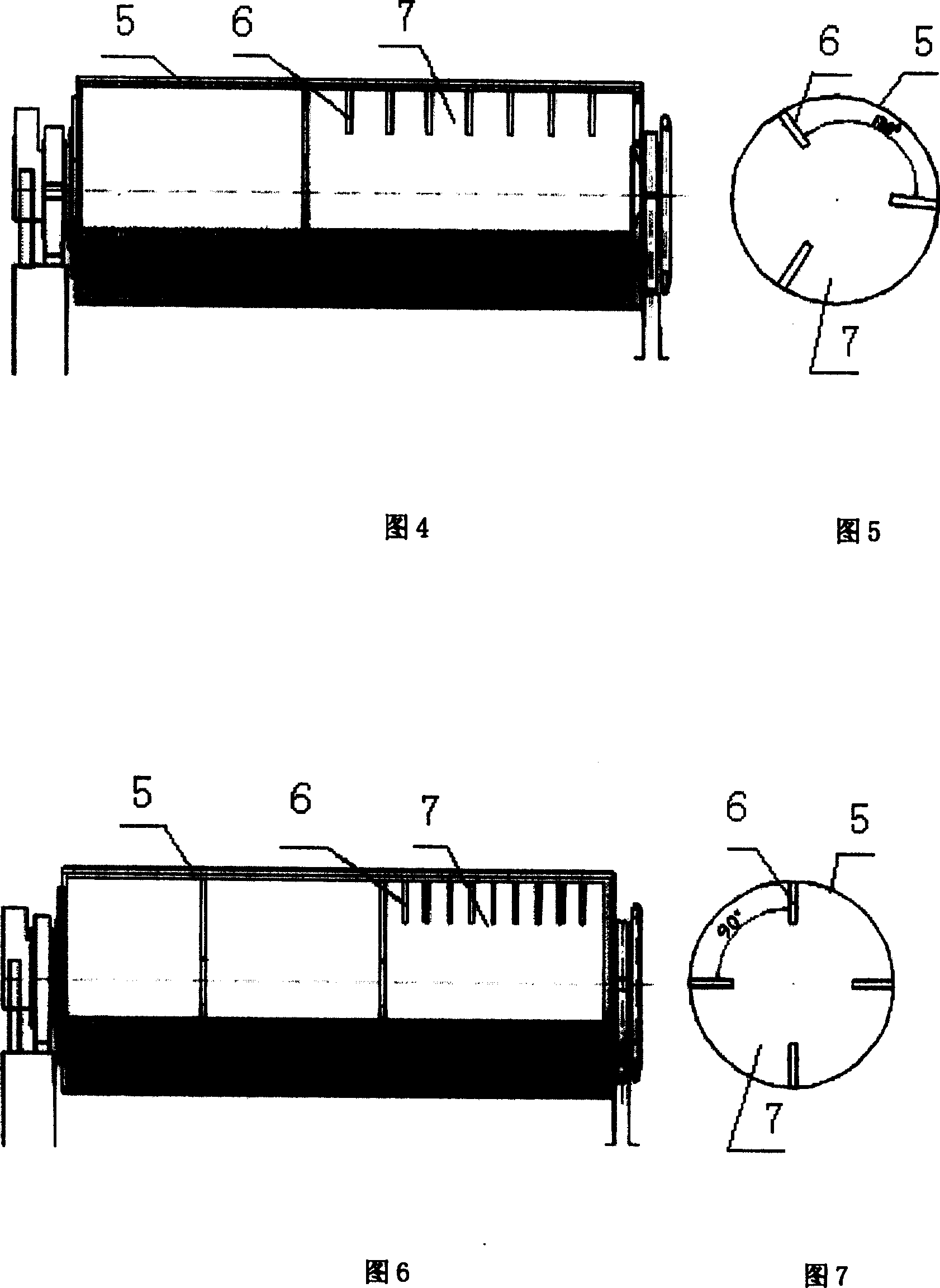

[0028] As shown in Fig. 6 and Fig. 7, when used in a tube mill, the length of the rotating cylinder 5 of the tube mill is 12m, and the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com