Enzyme deactivation cylinder

A technology of fixing and fixing device, applied in the field of fixing cylinder, can solve the problems of rapid cooling and heating of the cylinder wall, insufficient fixing, slow and orderly, etc., and achieve the effects of eliminating clumping, even and sufficient fixing, and constant temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

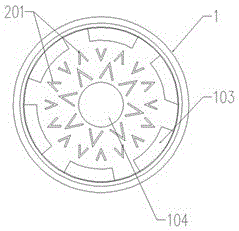

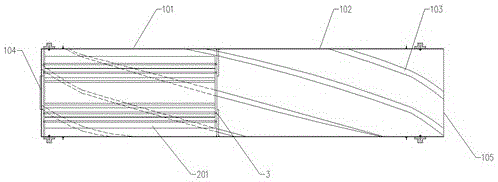

[0025] Implementation mode one: if figure 1 As shown, a kind of killing cylinder includes a killing cylinder 1, the inner wall of the killing cylinder 1 is provided with a guide vane plate 103, and the killing cylinder 1 includes a high-fire killing section 101 and a medium / low temperature killing section 102, and the high-fire killing section 101 The length ratio of the middle / low temperature fixing section 102 is about 1:2, the high fire fixing section 101 is provided with a feed inlet 104, the medium / low temperature fixing section 102 is provided with a discharge port 105, and the high fire fixing section 101 area is provided with a There is a killing device 2, the length of the killing device 2 is not less than the length of the high-fire killing section 101, and the killing device 2 is composed of a number of angle steel structures 201 evenly arranged on the two concentric circles of the killing cylinder 1 cylinder, wherein, the inner The angle steel structures 201 of the...

Embodiment approach 2

[0028] Implementation mode two: if Figure 6-8 As shown, the difference from Embodiment 1 is that the fixing device 2 is a fixing rod 202, and the fixing rod 202 includes a main rod 2021, and a plurality of branches 2022 are arranged on the main rod 2021, and the main rods 2021 are evenly arranged on one of the fixing cylinders 1. On the concentric circles, the branch-killing rod 2022 is in a "V" shape, and the "V"-shaped bifurcation of the branch rod 2022 points to the center of the killing cylinder 1. Wherein, the main rod 2021 and the branch rod 2022 can be made of metal round rods or tubes with good thermal conductivity.

[0029] The beneficial effect of this embodiment is: it is suitable for small-sized fixing cylinder 1, and when the space is limited, the fixing rod 202 is used to arrange the fixing rod 202. Set "V" shaped sticks 2022 on the top, or arrange them in a joint manner. The sticks 2022 break up the tea balls and delay the walking time of the tea leaves, so as...

Embodiment approach 3

[0030] Implementation mode three: if Figure 9-10As shown, the difference from the second embodiment is that the greening rods 202 of the greening device 2 are arranged in two concentric circles, and the positions of the greening rods 202 of the inner and outer circles are staggered to increase the contact surface and contact time with the tea leaves. The efficiency of loose tea group is improved.

[0031] The following table is the comparison of the parameters of adopting conventional methods to complete and adopting the present invention to complete.

[0032]

[0033] Conventional + heat exchanger

[0034] The above summary data answer has been obtained through many experiments: the combination of the conventional de-enzyming cylinder 1 and the de-enzyming device 2 of the present invention solves the technical problem that it is difficult to maintain high-temperature de-enzyming in the tea de-enzyming process. The problem of frying the green leaves that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com