Leather mechanical roller coater

A roller coater and mechanical technology, applied in leather surface treatment, small raw hide/large hide/leather/fur treatment, leather/skin/leather/raw hide chemical treatment equipment, etc. Inconvenient work, difficult to control and other problems, to achieve the effect of ensuring the quality of leather finishing and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

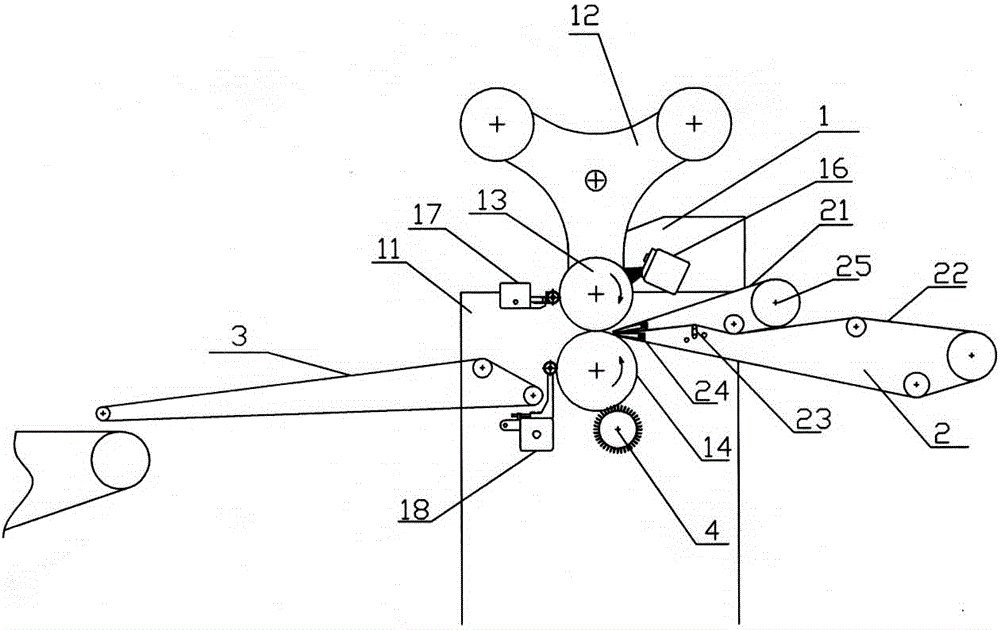

[0030] Such as figure 1 Shown, a kind of leather mechanical roller coater, comprises host machine 1, skin feeding machine 2 and leather picker 3; Adjusting device 15, scraper device 16, skinning roller device 17 and peeling roller device 18; Roller changing frame 12 is triangular, and it is installed on the frame 11 by shaft, and drives operation by motor, is used for rubber coating roller Replacement; the rubber coating roller 13 is installed on the roller stand 12, and the steel pressure roller 14 is installed on the pressure roller adjustment device 15 through a bracket.

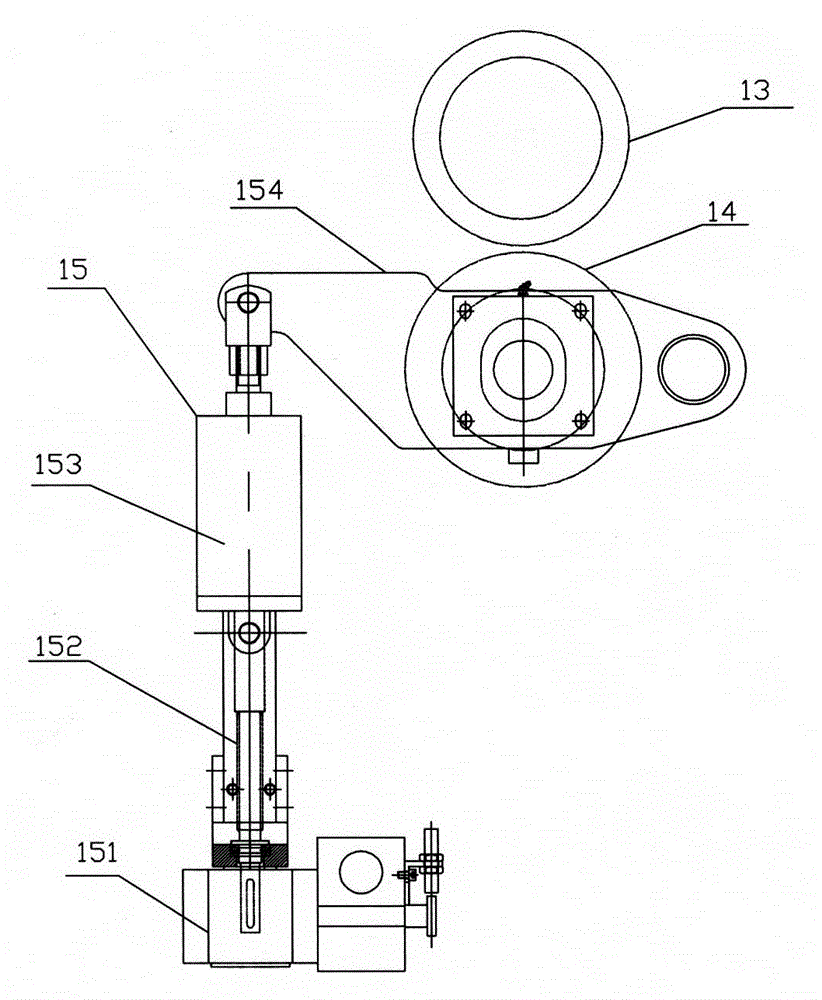

[0031] Such as figure 2 As shown, the pressure roller adjustment device 15 includes a one-piece reducer 151, a fine-tuning screw 152, a first cylinder 153, and a pressure roller adjustment arm 154 connected in sequence. In the working state, the reducer drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com