Equipment for processing parts with high-pressure liquid

A high-pressure liquid and component technology, applied in the field of water processing, can solve the problems of burr sticking to the surface and scratching the surface, so as to improve the processing effect, improve work efficiency and ensure the finishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

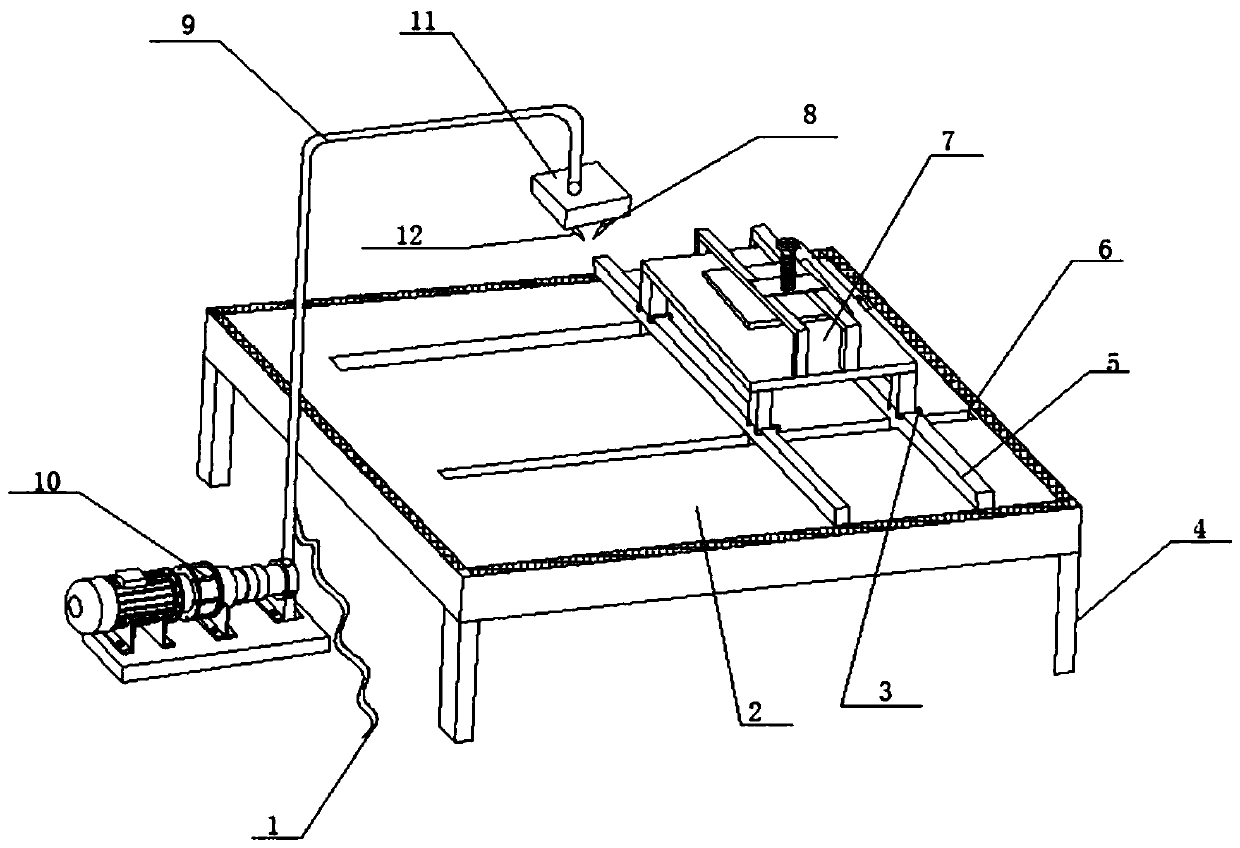

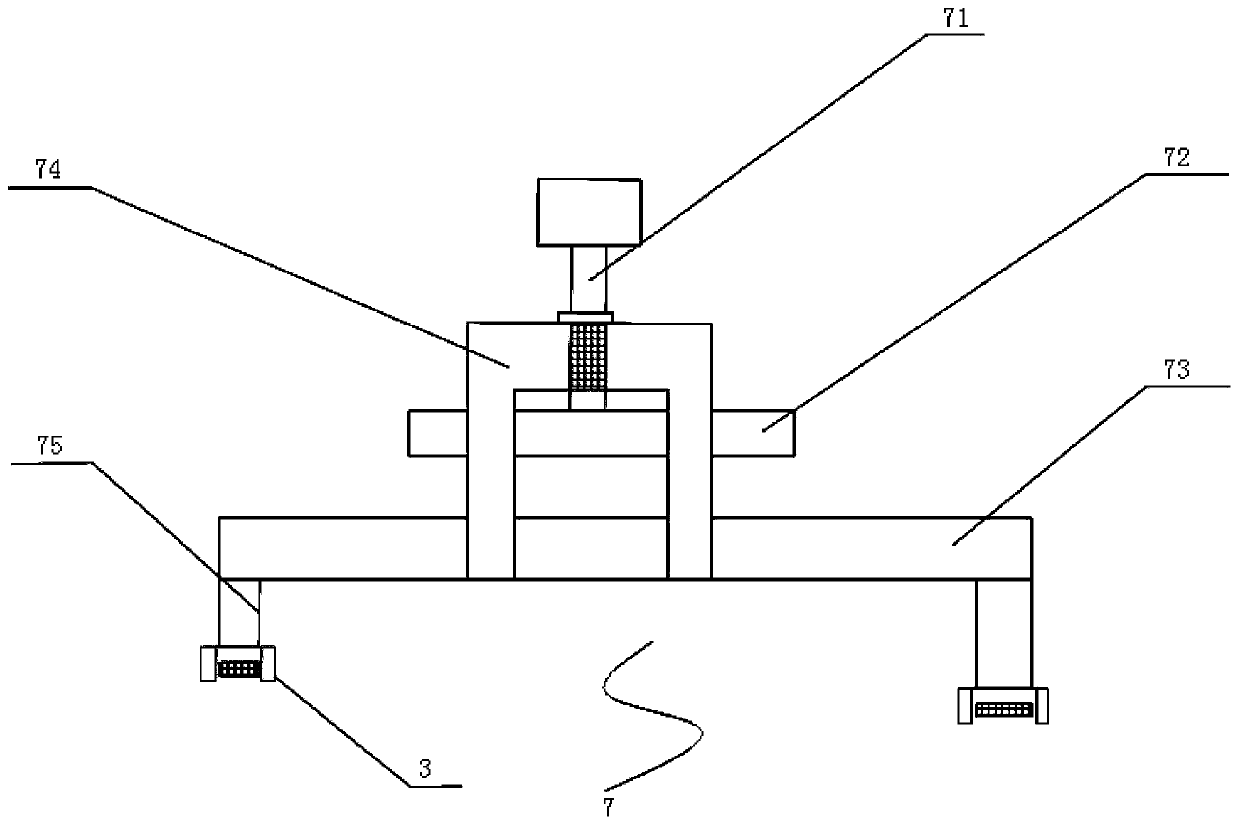

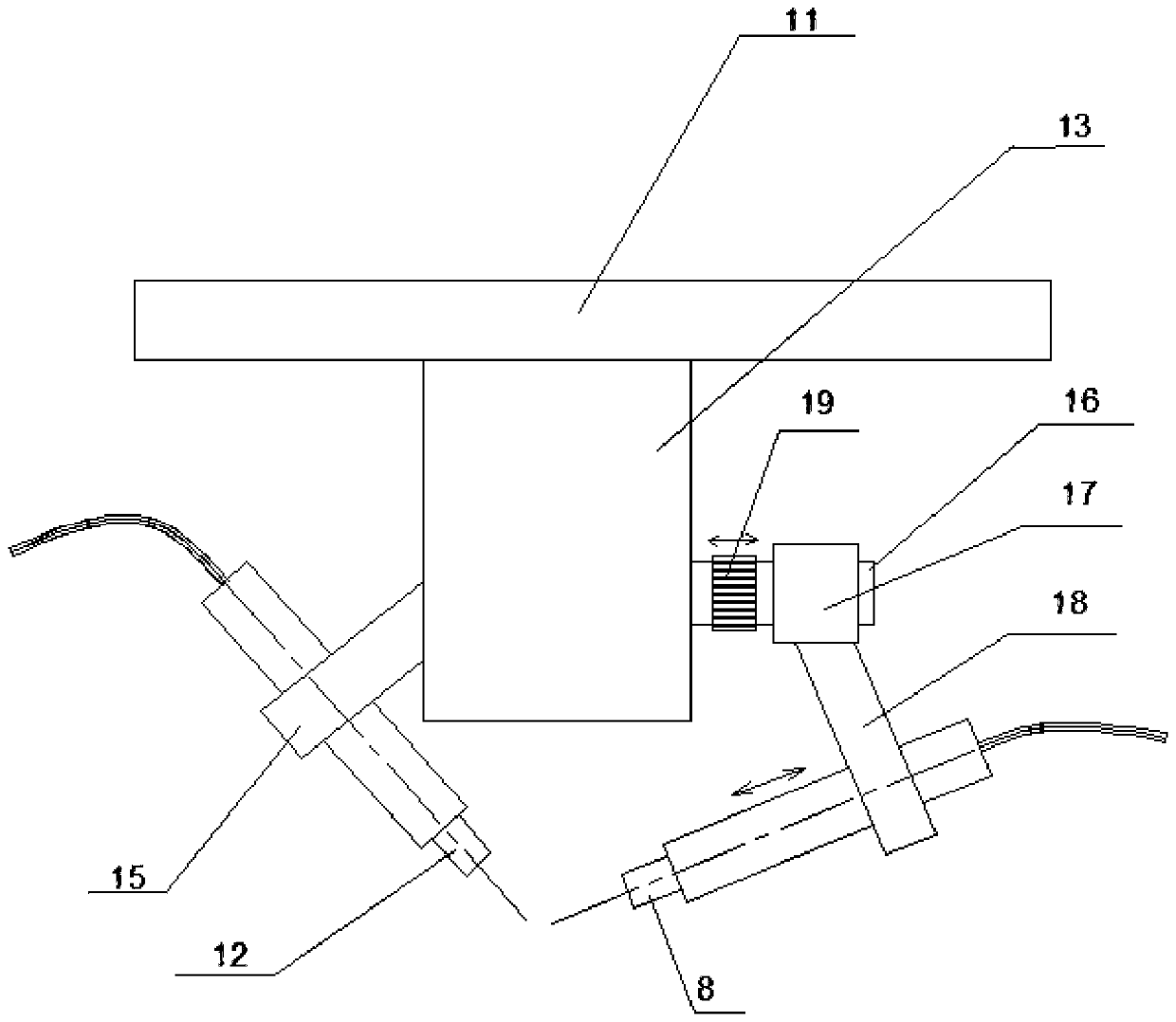

[0025] see Figure 1~4 , in the embodiment of the present invention, a kind of equipment of high-pressure liquid processing parts, it is used for finishing and deburring the surface of the workpiece, which includes a processing table 2, a workpiece positioning device 7, a high-pressure liquid processing head, a three-dimensional moving plate 11 and Booster pump 10, wherein the workpiece positioning device is provided on the processing table 2, a three-dimensional moving plate 11 is arranged above the processing table 2, and the high-pressure liquid processing plate 11 is arranged on the bottom of the three-dimensional moving plate 11. The high-pressure liquid processing head is connected with the booster pump 10, and it is characterized in that the high-pressure liquid processing head includes a main high-pressure spray head 12 and a secondary high-pressure spray head 8, wherein the main high-pressure spray head 12 is fixed Connected to the three-dimensional movable disk 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com