Ultra high temperature ceramic based aerogel material and preparation method thereof

A technology of ultra-high temperature ceramics and aerogels, which can be applied to ceramic products, other household appliances, household appliances, etc., and can solve the problems of easy pulverization of precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of precursor sol

[0033] In one embodiment, in order to prepare transition metal boride / silicon carbide composite airgel material or transition metal boride / transition metal carbide / silicon carbide composite airgel material, soluble transition metal precursor, organic silicon ( Silicon source), soluble carbon source and boron source are dissolved in the solvent to form a mixed solution. In another embodiment, in order to prepare a transition metal carbide / silicon carbide composite airgel material, a soluble transition metal precursor, organic silicon and a soluble carbon source are dissolved in a solvent to form a mixed solution. "Soluble" here means being soluble in the above-mentioned solvents. When forming the mixed solution, the order of adding the raw materials is not limited, as long as the raw materials are mixed uniformly.

[0034] The soluble transition metal precursor can be an oxychloride or hydroxide containing the transition metal, or an orga...

Embodiment 1

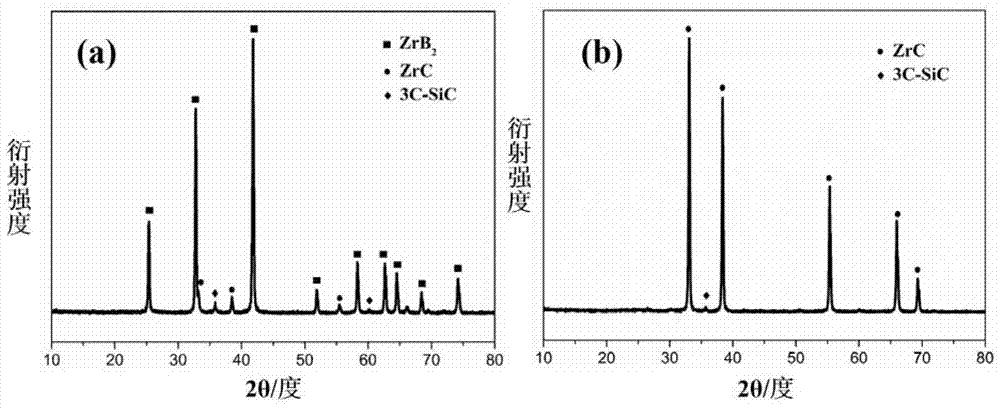

[0045] Add 50g of zirconium n-butoxide and 10g of ethyl orthosilicate dropwise into 50g of ethanol and stir to mix. After stirring for 30 minutes, add 44.42g of glycerol according to the C / Zr molar ratio of 10 and the C / Si molar ratio of 3 , Add 56.95g of triethyl borate according to the B / Zr molar ratio of 3, and react in a water bath at 40°C for 2 hours to obtain the precursor of zirconium boride / silicon carbide; pour the precursor into a beaker and place it in an oven at 90°C for curing for 12 Hours, after curing, naturally cool to room temperature and demould to obtain the zirconium boride / silicon carbide precursor xerogel; place the xerogel in an electric furnace and heat it to 1600°C for 2 hours under an argon atmosphere to make it Carbothermal reduction reaction; after the reaction, naturally cool to room temperature.

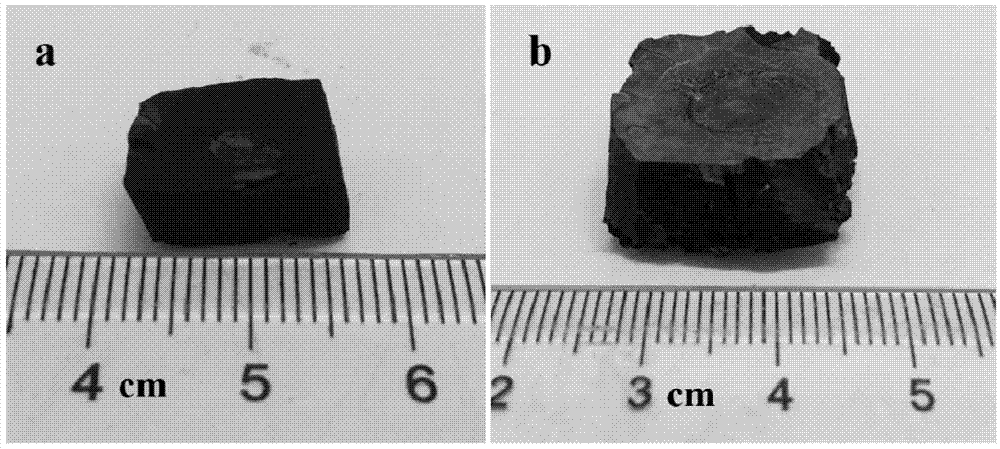

[0046] In the experiment, the photo of the zirconium boride / silicon carbide airgel obtained through high-temperature carbothermal reduction reaction is ...

Embodiment 2

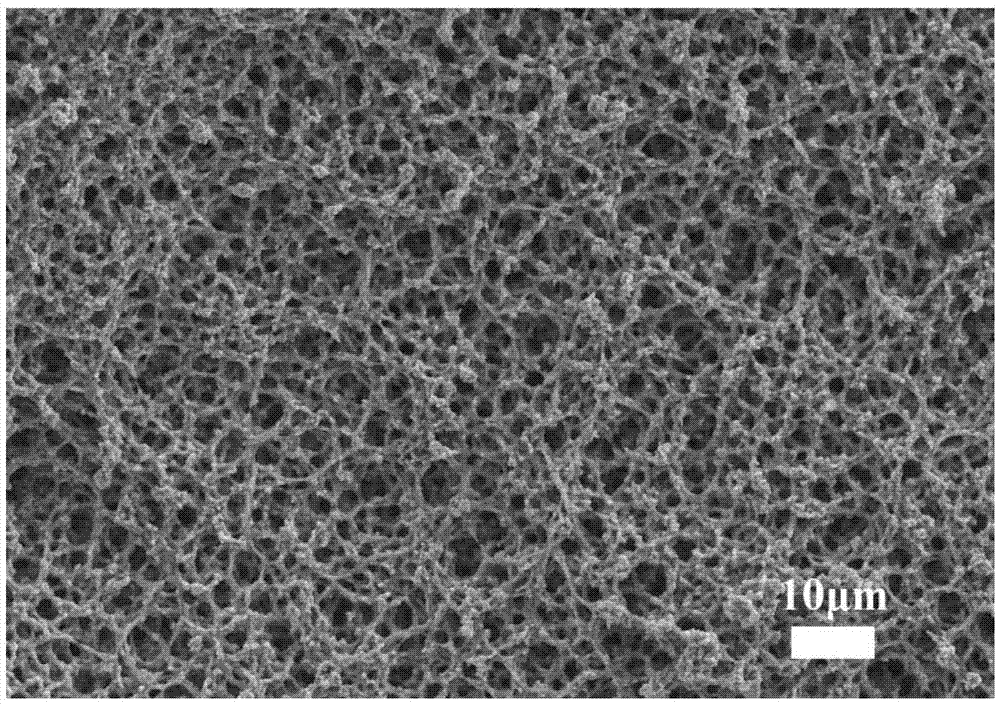

[0048] In order to prepare zirconium boride / silicon carbide airgel material, 50g of zirconium n-butoxide and 10g of ethyl orthosilicate were added dropwise to 50g of ethanol and stirred and mixed. After stirring for 30 minutes, according to the C / Zr molar ratio of 10, When the C / Si molar ratio is 3, add 44.42 g of glycerol, and when the B / Zr molar ratio is 10, add 189.8 g of triethyl borate. All the other operations are the same as described in Example 1. The porosity, pore size distribution and density of the prepared airgel material were measured by mercury intrusion porosimetry, wherein the porosity was 80.9%, the pore diameter was 0.8-1.2 μm, and the density was 0.76 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com