Efficient low-cost method for machining monocrystalline and polycrystalline silicon pieces through diamond wire

A polycrystalline silicon wafer and diamond wire technology, which is used in stone processing equipment, fine working devices, working accessories, etc. Frequent problems such as increasing processing efficiency, increasing processing speed, and enhancing processing stability can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

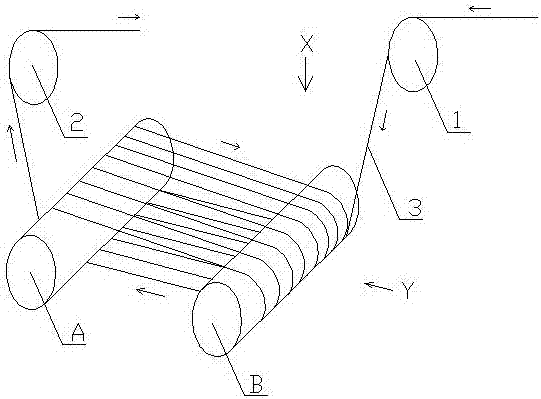

[0033] A kind of efficient, low-cost diamond wire processing method for single polycrystalline silicon wafer, it is characterized in that, its steps are as follows:

[0034] (1) Assemble the silicon rods to the diamond wire cutting machine;

[0035] (2) Parameter setting of diamond wire cutting machine;

[0036] (A) Set the reciprocating distance of the diamond wire, set the forward distance of the diamond wire to 3700 meters, and the return distance to 3700 meters;

[0037] (B) Cooling water temperature and flow setting, set the cooling water temperature to 20°C, set the flow rate to 7000 liters per hour,

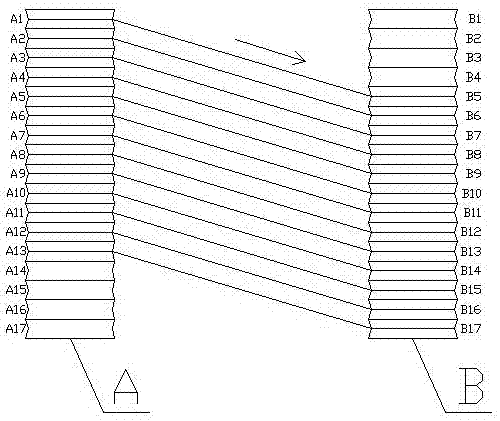

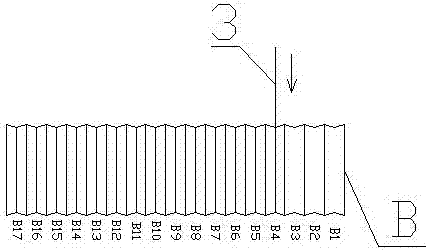

[0038] (C) Network wiring setting, the diamond wire is guided into the fourth wire groove B4 of the wire guide roller through the wire inlet guide wheel, and then wound around the first wire groove A1 of the wire outlet guide roller, and the diamond wire comes out of the first wire groove A1 of the wire outlet guide roller Finally, it is introduced into the fifth slot B5...

experiment example 2

[0042] A kind of efficient, low-cost diamond wire processing method for single polycrystalline silicon wafer, it is characterized in that, its steps are as follows:

[0043] (1) Assemble the silicon rods to the diamond wire cutting machine;

[0044] (2) Parameter setting of diamond wire cutting machine;

[0045] (A) Set the reciprocating distance of the diamond wire, set the forward distance of the diamond wire to 4500 meters, and the return distance to 4500 meters;

[0046] (B) Cooling water temperature and flow setting, set the cooling water temperature to 20°C, set the flow rate to 7000 liters per hour,

[0047] (C) Network wiring setting, the diamond wire is guided into the fourth wire groove B4 of the wire guide roller through the wire inlet guide wheel, and then wound around the first wire groove A1 of the wire outlet guide roller, and the diamond wire comes out of the first wire groove A1 of the wire outlet guide roller Finally, it is introduced into the fifth slot B5...

experiment example 3

[0051] A kind of efficient, low-cost diamond wire processing method for single polycrystalline silicon wafer, it is characterized in that, its steps are as follows:

[0052] (1) Assemble the silicon rods to the diamond wire cutting machine;

[0053] (2) Parameter setting of diamond wire cutting machine;

[0054] (A) The reciprocating distance setting of the diamond wire, set the forward distance of the diamond wire to 4000 meters, and the return distance to 4000 meters;

[0055] (B) Cooling water temperature and flow setting, set the cooling water temperature to 20°C, set the flow rate to 7000 liters per hour,

[0056](C) Network wiring setting, the diamond wire is guided into the fourth wire groove B4 of the wire guide roller through the wire inlet guide wheel, and then wound around the first wire groove A1 of the wire outlet guide roller, and the diamond wire comes out of the first wire groove A1 of the wire outlet guide roller Finally, it is introduced into the fifth slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com