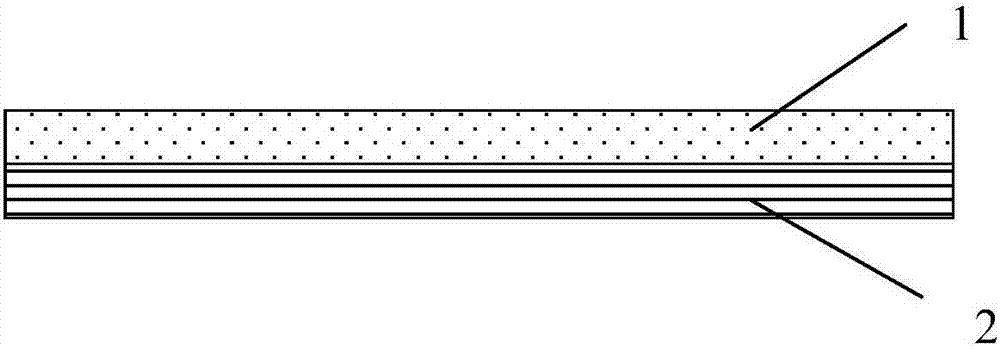

Polyacrylonitrile/fluorinated graphene oxide/Celgard composite membrane

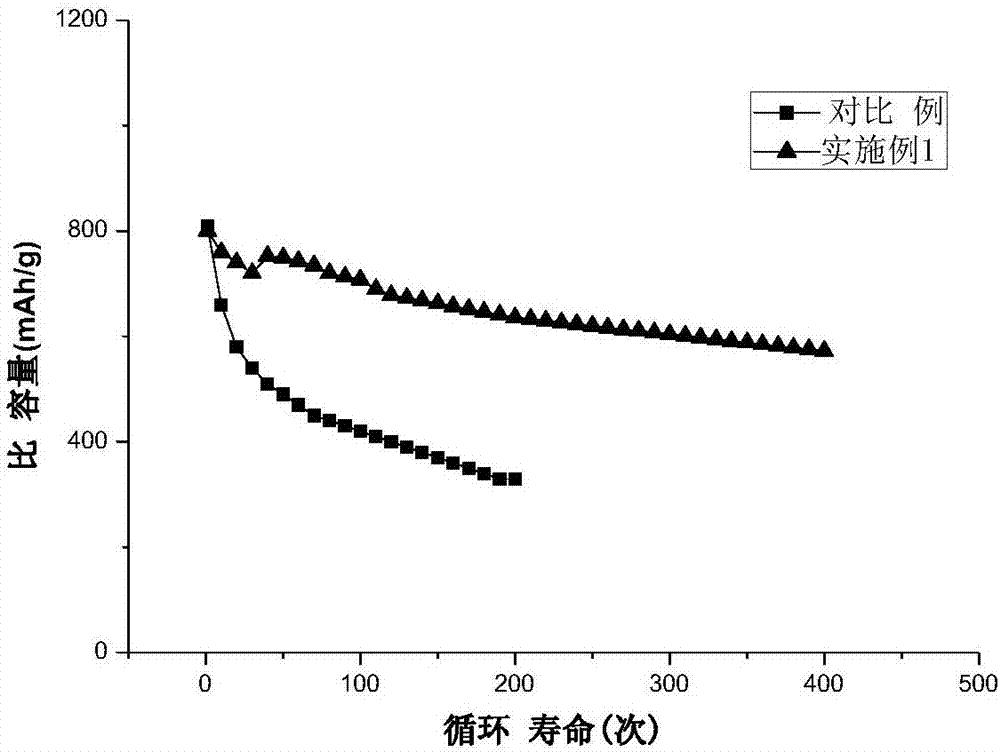

A technology of polyacrylonitrile and composite diaphragm, which is applied in the direction of separator/film/diaphragm/spacer components, electrical components, circuits, etc., and can solve the problems of reducing the utilization rate of sulfur active materials, slow migration speed, and lithium-sulfur battery safety, etc. problem, achieve the effect of reducing the shuttle effect and increasing the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

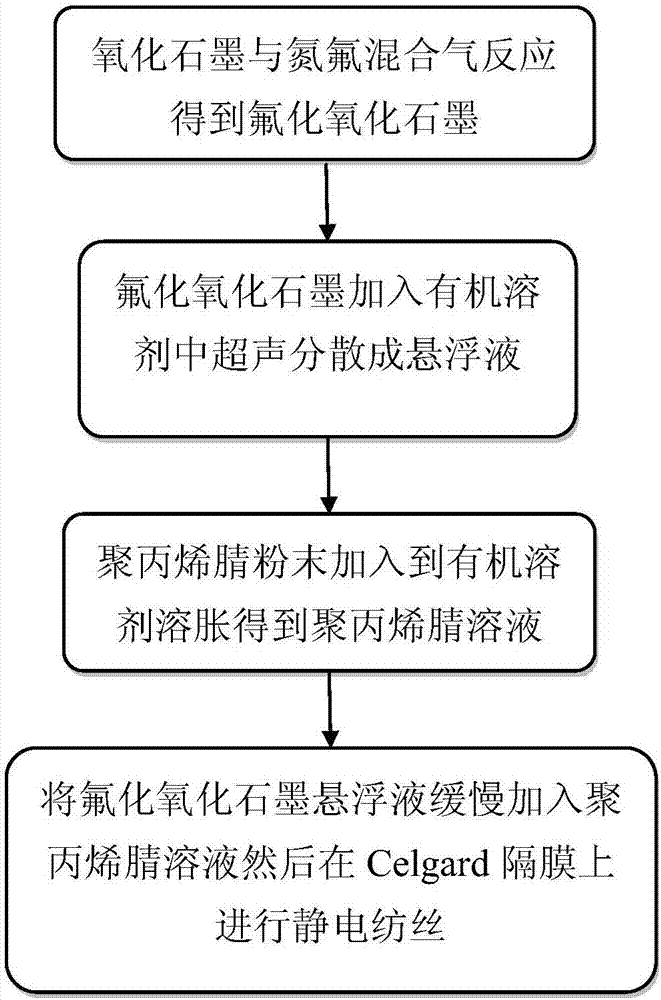

[0020] (1) Put graphite oxide into a muffle furnace and heat it to 50°C for 60 minutes. The reaction atmosphere is nitrogen-fluorine mixed gas containing 5% fluorine gas. After the reaction is completed, cool naturally to obtain fluorinated graphite oxide;

[0021] (2) Add 10g of fluorinated graphite oxide into 100g of N-methylpyrrolidone and disperse ultrasonically for 5 hours to form a suspension;

[0022] (3) Add 2g of commercial polyacrylonitrile powder into 20g of N-methylpyrrolidone, swell for 24 hours, heat to 50°C, and stir for 5 hours to obtain a polyacrylonitrile solution;

[0023] (4) Slowly add the suspension into the polyacrylonitrile solution, and react with mechanical stirring for 1 hour to obtain the polyacrylonitrile / fluorinated graphite oxide spinning stock solution, which is electrospun on a Celgard diaphragm to obtain polyacrylonitrile / fluorinated graphite oxide Graphene / Celgard composite separator.

Embodiment 2

[0025] (1) Put graphite oxide into a muffle furnace and heat it to 200°C for 10 minutes to react. The reaction atmosphere is a nitrogen-fluorine mixed gas containing 10% fluorine gas. After the reaction is completed, it is naturally cooled to obtain fluorinated graphite oxide;

[0026] (2) Add 10g of fluorinated graphite oxide into 1000g of dimethyl sulfoxide, and ultrasonically disperse for 0.5 hours to form a suspension;

[0027] (3) Add 10g of commercial polyacrylonitrile powder into 1000g of dimethyl sulfoxide, swell for 24 hours, heat to 50°C, and stir for 0.5 hours to obtain a polyacrylonitrile solution;

[0028] (4) Slowly add the suspension to the polyacrylonitrile solution, and react with mechanical stirring for 5 hours to obtain a polyacrylonitrile / fluorinated graphite oxide spinning stock solution, which is electrospun on a Celgard diaphragm to obtain polyacrylonitrile / fluorinated graphite oxide Graphene / Celgard composite separator.

Embodiment 3

[0030] (1) Put graphite oxide into a muffle furnace and heat it to 100°C for 30 minutes to react. The reaction atmosphere is a nitrogen-fluorine mixed gas containing 7% fluorine gas. After the reaction is completed, it is naturally cooled to obtain fluorinated graphite oxide;

[0031] (2) Add 10g of fluorinated graphite oxide into 500g of N,N-dimethylformamide, and ultrasonically disperse for 3 hours to form a suspension;

[0032] (3) Add 5g of commercial polyacrylonitrile powder to 250g of N,N-dimethylformamide, swell for 24 hours, heat to 65°C, and stir for 2.5 hours to obtain a polyacrylonitrile solution;

[0033] (4) Slowly add the suspension into the polyacrylonitrile solution, and react with mechanical stirring for 3 hours to obtain a polyacrylonitrile / fluorinated graphite oxide spinning stock solution, which is electrospun on a Celgard diaphragm to obtain polyacrylonitrile / fluorinated graphite oxide Graphene / Celgard composite separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com