Steel plate used for producing low-temperature hot-stamped automobile part as well as manufacturing method of steel plate and use of steel plate

A technology of auto parts and manufacturing methods, which is applied in the direction of manufacturing tools, temperature control, rolling force/roll gap control, etc., and can solve problems such as difficult control of springback, cracking of body parts, affecting the dimensional accuracy of parts and body assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A-F

[0062] Embodiment A-F and comparative example G

[0063] The steel plate in above-mentioned embodiment and comparative example adopts following steps to make:

[0064] (1) Smelting: adopt converter smelting, control the mass percent of each chemical element as shown in Table 1;

[0065] (2) Casting: casting slabs are obtained through continuous casting;

[0066] (3) Hot rolling: the billet is heated to 1200-1250°C and then controlled rolling, the starting rolling temperature is 950-1150°C, the final rolling temperature is 800-900°C, and the thickness of the hot-rolled plate is usually controlled between 3-4mm , the coiling temperature is 500-800°C, and then cooled to room temperature, so that the microstructure is all martensitic;

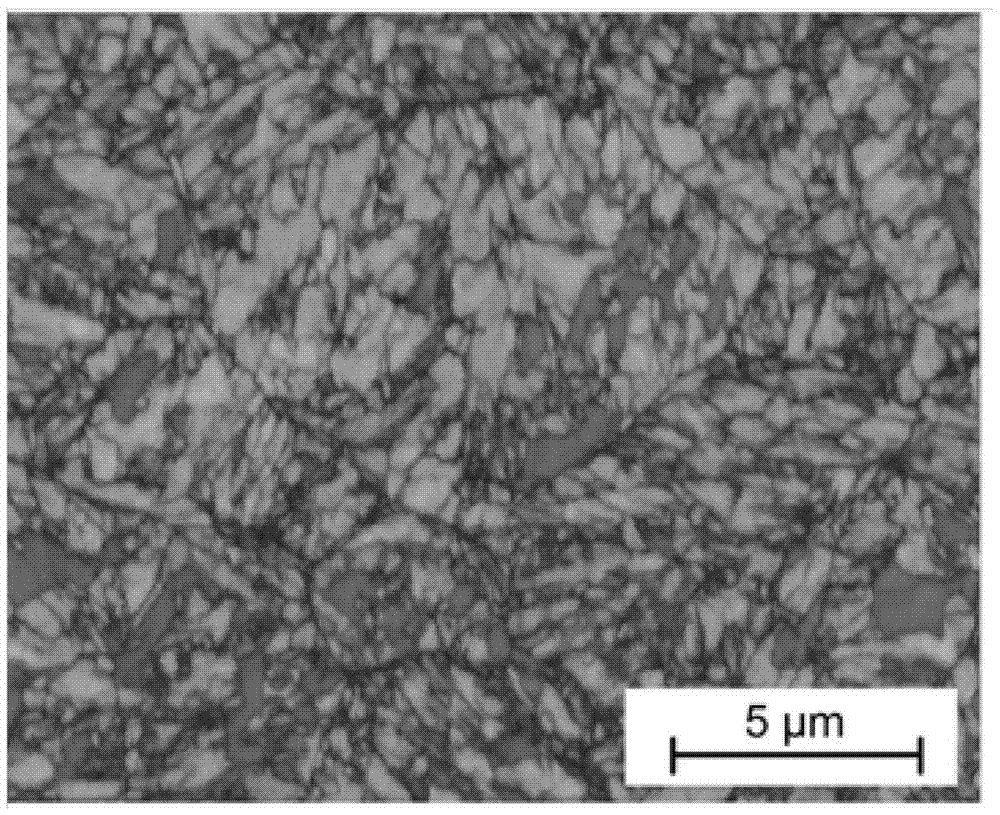

[0067] (3a) Annealing: Annealing in a bell furnace, the annealing temperature is 580-860°C, and the annealing time is 6-96hr. The microstructure obtained after annealing contains a certain volume fraction of austenite, so as to improve the plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com