Black glass fiber and preparation method thereof

A glass fiber and black glass technology, applied in the field of black glass fiber and its preparation, can solve the problems of uneven dyeing, easy falling off, poor coloring, etc., and achieve the effects of simplifying the preparation process, reducing the molding temperature and saving the production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

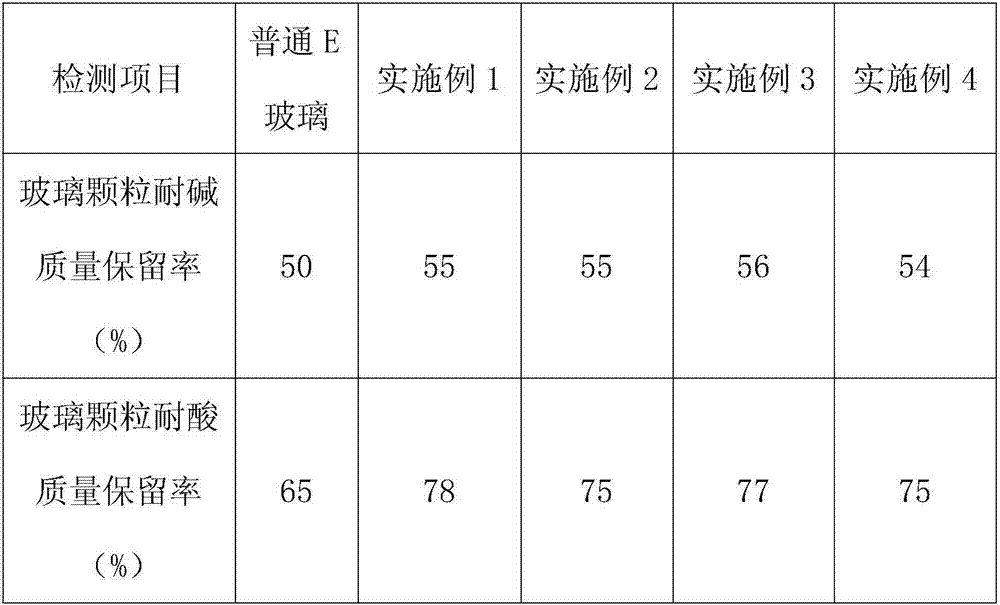

Examples

Embodiment 1

[0045] Prepare the required raw materials and prepare the ingredients according to the following parts by weight: 23 parts of basalt, 6.5 parts of boronite, 36 parts of pyrophyllite, 14 parts of quicklime, 14 parts of quartz powder, 4 parts of ferric oxide, and 2.5 parts of titanium dioxide. The raw materials are mixed into a batch, and mixed 18 times in a mixing tank with a pressure of 300kPa to obtain a uniform batch. The uniform batch is sent to a 1320°C pool kiln through a kiln head silo and a screw feeder for melting, clarification and homogenization to obtain a black The molten glass, and then the molten glass flows out and enters the main passage at 1270°C, the distribution passage at 1210°C, the working passage at 1150°C, and then enters the platinum-rhodium alloy leakage plate with a leak nozzle at the bottom through the flow tank. The diameter of the molten glass is 1.5- The 2mm nozzle flows out to obtain liquid black glass filaments. The length of the liquid glass fi...

Embodiment 2

[0047] Prepare the required raw materials and prepare the ingredients according to the following parts by weight: 24 parts of basalt, 6 parts of boronite, 33 parts of pyrophyllite, 14 parts of quicklime, 14 parts of quartz powder, 5 parts of ferric oxide, 2 parts of titanium dioxide, and The above-mentioned raw materials are mixed into a batch, and mixed 15 times in a mixing tank with a pressure of 320kPa to obtain a uniform batch. The uniform batch is sent into a 1350°C tank kiln through a kiln head silo and a screw feeder for melting, clarification and homogenization to obtain Black molten glass, and then the molten glass flows out and enters the main passage at 1260°C, the distribution passage at 1240°C, the working passage at 1180°C, and then enters the platinum-rhodium alloy drain plate with a leak nozzle at the bottom through the flow tank. The diameter of the molten glass is within 1.5 The length of the liquid glass filament is 4mm, and the liquid black glass filament is...

Embodiment 3

[0049]Prepare the required raw materials and prepare the ingredients according to the following parts by weight: 25 parts of basalt, 6.5 parts of boronite, 34 parts of pyrophyllite, 13.5 parts of quicklime, 14 parts of quartz powder, 5.5 parts of ferric oxide, 1.5 parts of titanium dioxide, and The above raw materials are mixed into a batch, mixed 12 times in a mixing tank with a pressure of 330kPa to obtain a uniform batch, and the uniform batch is sent into a 1330°C pool kiln through a kiln head silo and a screw feeder for melting, clarification and homogenization to obtain Black molten glass, and then the molten glass flows out into the main passage at 1270°C, the distribution passage at 1220°C, the working passage at 1160°C, and then enters the platinum-rhodium alloy drain plate with a leak nozzle at the bottom through the flow tank. The diameter of the molten glass is within 1.5 The length of the liquid black glass filament is 5mm, and the liquid black glass filament is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com