Production technology of activated carbon for high-capacity long-service-life supercapacitor

A technology for the production of supercapacitors and activated carbons, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

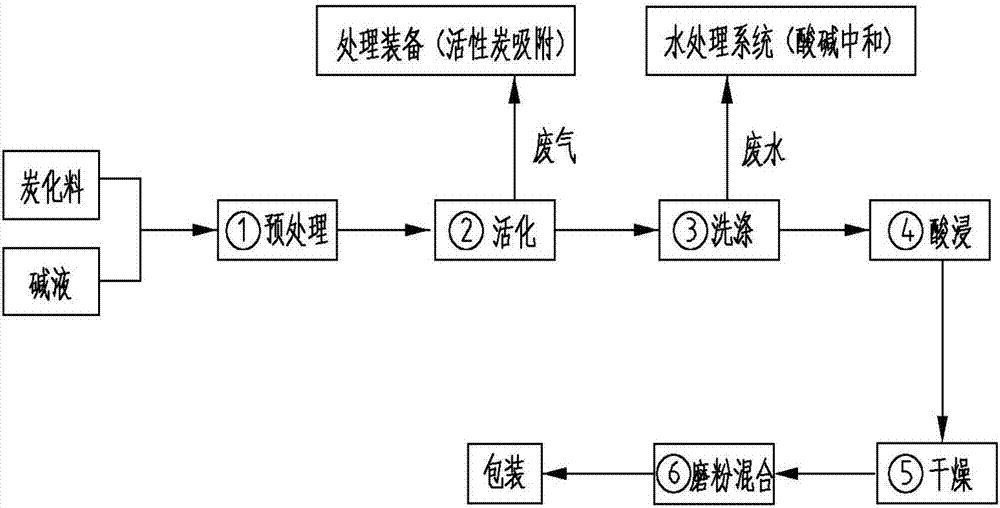

[0025] In order to solve the above-mentioned technical problems, the first embodiment provides such a production process of activated carbon for high-capacity and long-life supercapacitors, the process flow includes pretreatment, activation, washing, acid leaching, drying, grinding and mixing, such as figure 1 As shown, it specifically includes the following steps:

[0026] a. Pretreatment: Send 15Kg of carbonized raw materials (husks, charcoal or petroleum coke) to a pulverizer for preliminary crushing. During the crushing process, spray an ammonia solution with a mass fraction of 13%, the ammonia solution and the carbonized raw material The mass ratio is 1:15. After the crushing process is completed, the carbonized raw material and the KOH solution with a mass fraction of 27% are mixed and pretreated in a reaction tank at a temperature of 300°C for 3 hours at a mass ratio of 1:2.6. Obtain carbonized material;

[0027] b. Activation: After the carbonized material is fully kn...

Embodiment 2

[0035] A production process of activated carbon for high-capacity and long-life supercapacitors, the process flow includes pretreatment, activation, washing, acid leaching, drying, grinding and mixing, such as figure 1 As shown, it specifically includes the following steps:

[0036] a. Pretreatment: Send 15Kg of carbonized raw materials (husks, charcoal or petroleum coke) to a pulverizer for preliminary crushing. During the crushing process, spray an ammonia solution with a mass fraction of 14%, the ammonia solution and the carbonized raw material The mass ratio is 1:18. After the crushing process is completed, the carbonized raw material and the KOH solution with a mass fraction of 28% are mixed and pretreated in a reaction tank at a temperature of 350°C for 4.5 hours according to a mass ratio of 1:2.7. , to obtain carbonized material;

[0037] b. Activation: After the carbonized material is fully kneaded and solidified, the carbonized material is delivered to the microwave ...

Embodiment 3

[0045] A production process of activated carbon for high-capacity and long-life supercapacitors, the process flow includes pretreatment, activation, washing, acid leaching, drying, grinding and mixing, such as figure 1 As shown, it specifically includes the following steps:

[0046] a. Pretreatment: Send 15Kg of carbonized raw materials (husks, charcoal or petroleum coke) to a pulverizer for preliminary crushing. During the crushing process, spray an ammonia solution with a mass fraction of 15%, the ammonia solution and the carbonized raw material The mass ratio is 1:20. After the pulverization process is completed, the carbonized raw material and the KOH solution with a mass fraction of 29% are stirred and pretreated in a reaction tank at a temperature of 400°C for 6 hours at a mass ratio of 1:2.8. Obtain carbonized material;

[0047] b. Activation: After the carbonized material is fully kneaded and solidified, the carbonized material is delivered to the microwave reaction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com