Method for optical fiber sensing monitoring of steel reinforcement corrosion

An optical fiber sensing, steel corrosion resistance technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, using optical device, etc., can solve the problems of cumbersome data processing procedures, peeling of concrete protective layer, and high technical requirements of optical fiber sensing technology , to avoid external interference and damage to the strain gauge, the monitoring results are accurate and reliable, and the principle is scientific and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

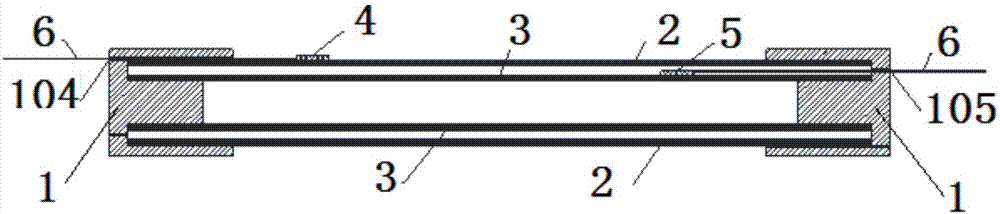

[0026] The technological process of the method for monitoring steel bar corrosion by optical fiber sensing involved in this embodiment includes two steps of preparing an optical fiber sensing monitoring device and monitoring the corrosion status of steel bars:

[0027] (1), preparing the optical fiber sensing and monitoring device includes four steps of preparing the sleeve, preparing the sensor, preparing the stage element and preparing the monitoring device:

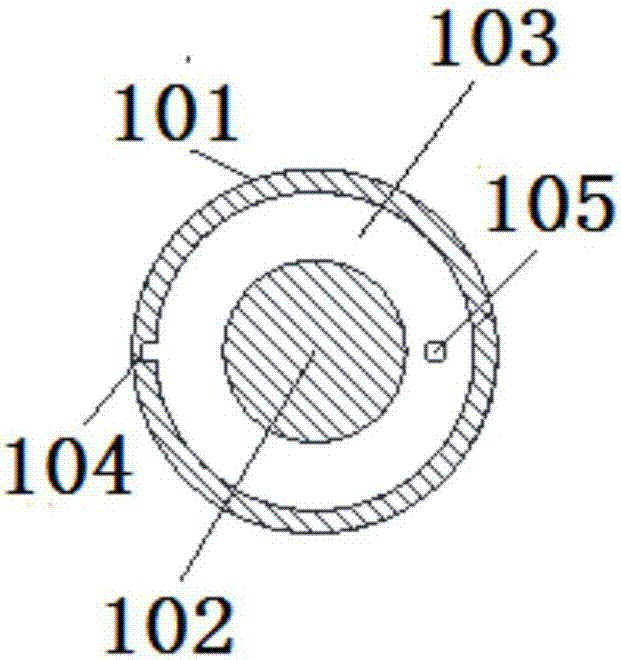

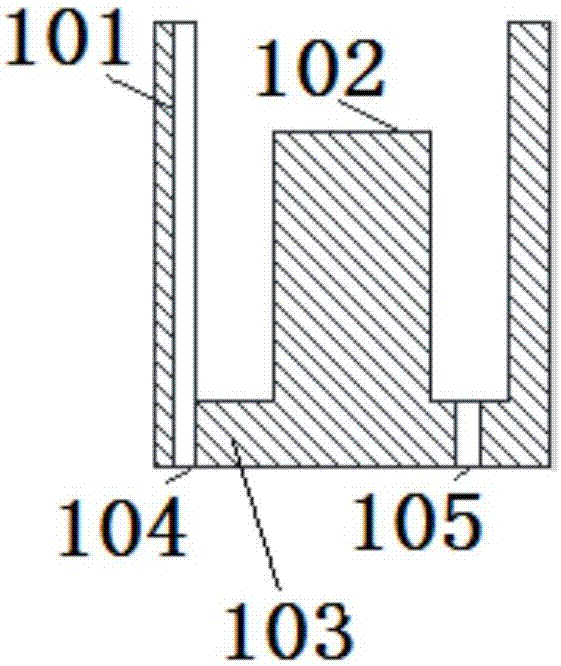

[0028] ①. Prepare the sleeve: adopt conventional stamping process, press and mold to prepare the sleeve 1 of cylindrical structure; the sleeve 1 is shown in figure 1 , the main structure of the sleeve 1 includes an outer circumference 101, an inner circular platform 102, a cylindrical bottom 103, a circumferential hole 104 and a cylindrical bottom hole 105, the outer periphery of the sleeve 1 is the outer circumference 101, and the inner center of the sleeve 1 is an inner circular platform 102 , the height of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com