Method for preparing solar cell absorber layer sb2se3 thin film based on magnetron sputtering and post selenization

A technology of solar cells and magnetron sputtering, which is applied in the direction of sputtering coating, coating, circuits, etc., can solve the problems of many defects, poor stability of solar cells, poor crystallinity of films, etc., and achieve single phase, simple equipment, Effects of loose control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

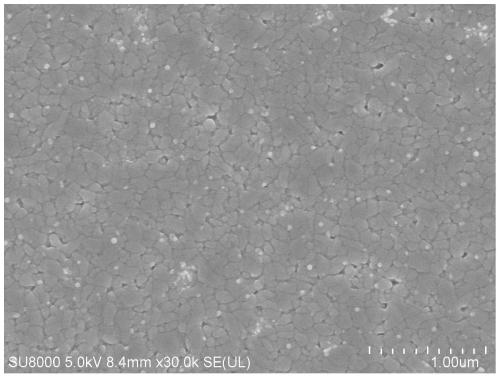

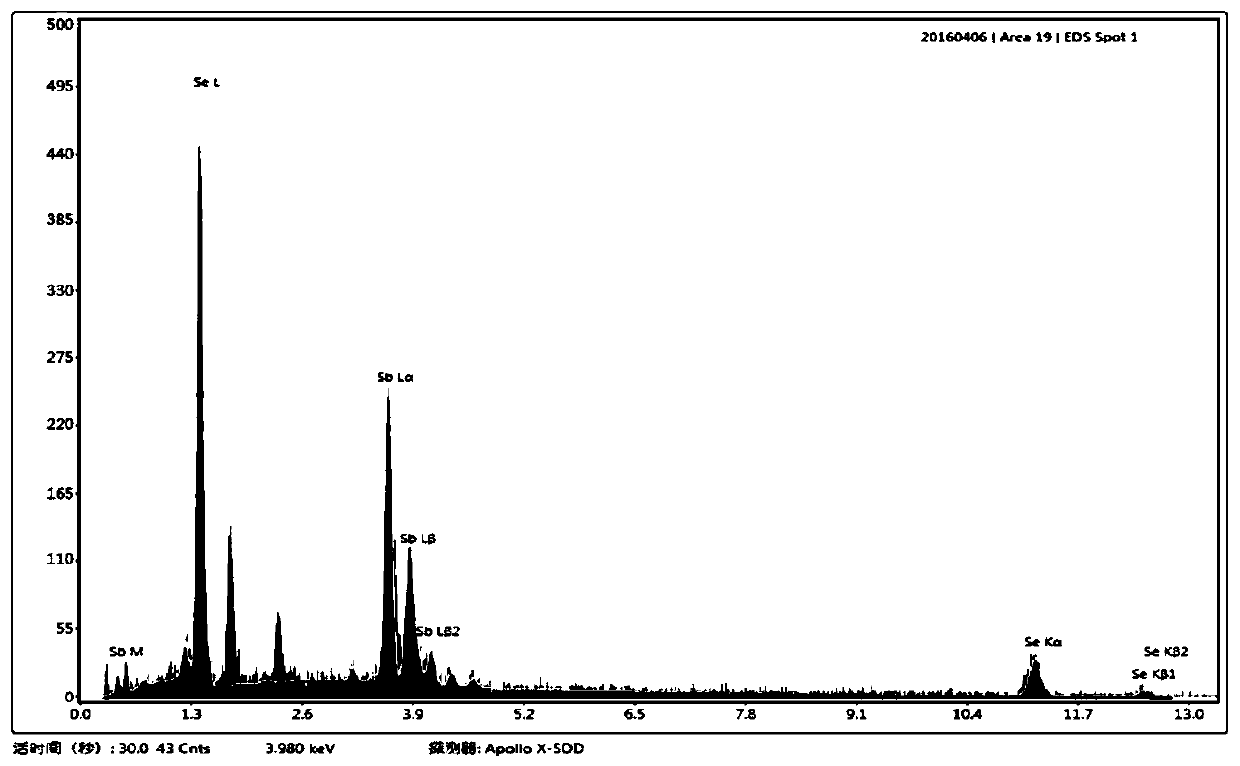

Image

Examples

Embodiment 1

[0041] 1. First, clean the molybdenum-coated glass substrate: immerse the molybdenum-coated glass substrate in sequence in detergent (60wt% sodium alkylsulfonate, 40wt% fatty alcohol ether sodium sulfate mixture), deionized water, 99% ethanol, 99.5% acetone solution, then cleaned in a plasma cleaner, and dried with nitrogen;

[0042] 2. Place the cleaned molybdenum-coated glass substrate in the magnetron sputtering studio;

[0043] 3. Use the magnetron sputtering coating system to pump the background vacuum of the magnetron sputtering coating system to less than 5.0pa;

[0044] 4. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0045] The sputtering gas uses argon with a purity of 99.9%;

[0046] The target material adopts Sb with a purity of 99.8% 2 Se 3 target;

[0047] The working air pressure in the magnetron sputtering studio is 0~0.2pa;

[0048] 5. The setting parameters are: power: 120W; gas flow: 60sccm; deposition time: ...

Embodiment 2

[0053] 1. First, clean the molybdenum-coated glass substrate: immerse the molybdenum-coated glass substrate in sequence in detergent (60wt% sodium alkylsulfonate, 40wt% fatty alcohol ether sodium sulfate mixture), deionized water, 99% ethanol, 99.5% acetone solution, then cleaned in a plasma cleaner, and dried with nitrogen;

[0054] 2. Place the cleaned molybdenum-coated glass substrate in the magnetron sputtering studio of the magnetron sputtering coating system;

[0055] 3. Use the magnetron sputtering coating system, the magnetron sputtering coating system is the existing technology (such as the magnetron sputtering coating equipment produced by the Institute of Microelectronics of the Chinese Academy of Sciences or the JGP series multi-target produced by Shenyang New Blue Sky Vacuum Technology Co., Ltd. Magnetron sputtering coating equipment), the background vacuum of the magnetron sputtering coating system is evacuated to less than 5.0pa;

[0056] 4. Sputtering gas Ar b...

Embodiment 3

[0065] 1. First, clean the soda-lime glass substrate: immerse the soda-lime glass substrate in sequence in detergent (60wt% sodium alkylsulfonate, 40wt% fatty alcohol ether sodium sulfate mixture), deionized water, 99% ethanol, 99.5% acetone solution, then cleaned in a plasma cleaner, and dried with nitrogen;

[0066] 2. Place the cleaned soda-lime glass substrate in the magnetron sputtering studio;

[0067] 3. Use the magnetron sputtering coating system to pump the background vacuum of the magnetron sputtering coating system to less than 5.0pa;

[0068] 4. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0069] The sputtering gas is argon with a purity of 99.9%;

[0070] The target material adopts Sb with a purity of 99.8% 2 Se 3 target;

[0071] The working air pressure in the magnetron sputtering studio is 0~0.2pa;

[0072] 5. The setting parameters are: power: 30W; gas flow: 60sccm; deposition time: 1.5h;

[0073] 6. The sput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com