Synthetic method and apparatus for trichlorosilane

A technology of trichlorosilane and synthesis method, which is applied in the direction of silicon compounds, silicon halide compounds, chemical instruments and methods, etc., which can solve the problems of narrow particle size range of silicon powder, shutdown for maintenance, enrichment, etc., and achieve improved gas-solid contact Effect of area, reduction of difficulty and cost, and reduction of difficulty coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for synthesizing trichlorosilane, in which silicon powder with a particle size ranging from 200 to 400 meshes is reacted with hydrogen chloride to synthesize trichlorosilane.

[0027] Preferably, the temperature of the reaction is 300-600° C., and the pressure is 0.01-1 MPa.

[0028] More preferably, the reaction temperature is 320-400°C.

[0029] Preferably, the silicon powder is one or more of silicon 1501, silicon 1502, silicon 2202, silicon 2502, silicon 3303, silicon 411, silicon 421, silicon 441, silicon 551, and silicon 553.

[0030] Preferably, the method for obtaining the silicon powder is to obtain the silicon powder with a particle size ranging from 200 to 400 meshes by doping relatively small particle silicon powder into relatively large particle silicon powder.

[0031] The trichlorosilane synthesis method in this example uses silicon powder with a particle size range of 200 to 400 meshes to prepare trichlorosilane. The si...

Embodiment 2

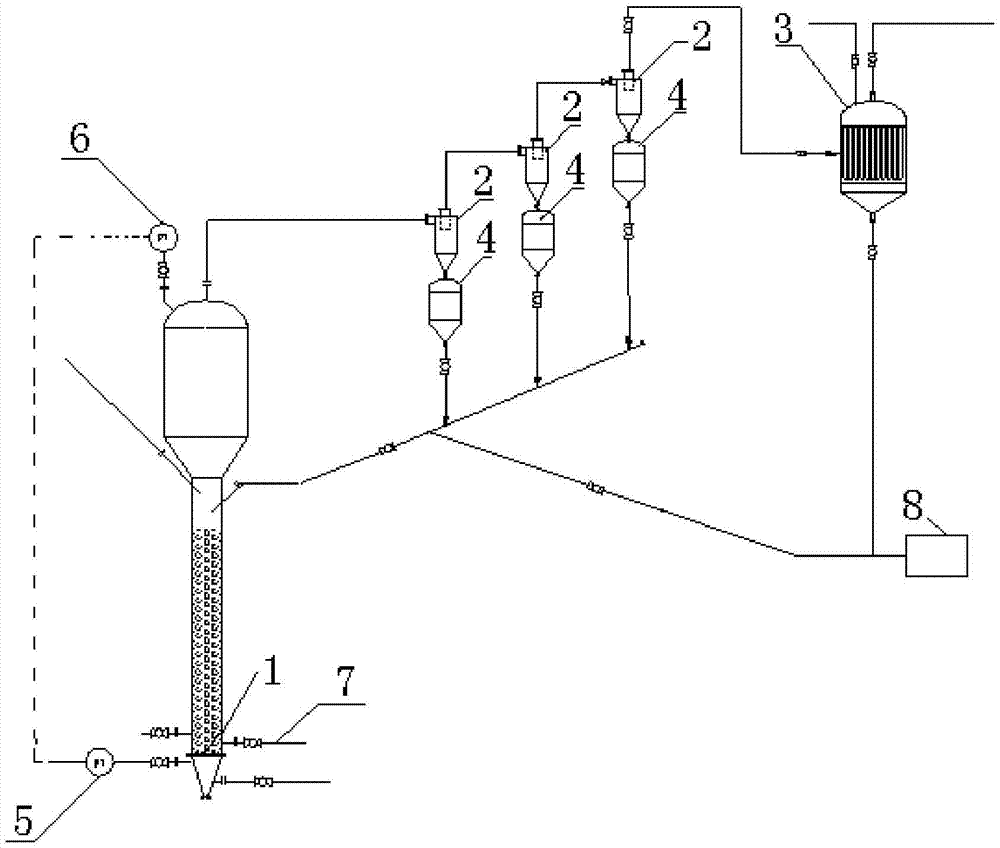

[0033] like figure 1 As shown, the present embodiment provides the trichlorosilane synthesis device used in the trichlorosilane synthesis method in Example 1, including:

[0034] Reactor 1, used for reacting silicon powder with a particle size ranging from 200 to 400 meshes and hydrogen chloride to obtain a first mixture, the first mixture including trichlorosilane;

[0035] A cyclone separator 2 is connected to the reactor 1, and the cyclone separator 2 is used to separate the first mixture from the silicon powder of large particles and the second mixture by cyclone;

[0036] A bag filter 3 is connected to the cyclone separator 2, and the bag filter 3 is used to separate the second mixture by filtering the silicon powder of small particles and a third mixture, and the third mixture includes trichlorosilane . The main component in the third mixture is trichlorosilane, part of silicon tetrachloride, and a small amount of dichlorosilane and silicon monochloride.

[0037] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com