A liquid electronic ink receiving medium

A technology for accepting media and electronic inks, applied in the direction of copying/marking methods, printing, etc., can solve the problems of poor surface gloss of printing media, and achieve the effect of bright colors, improved practicability, and easy mass printing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation of Cationic Inorganic Particle Dispersion:

[0046] According to the proportion, add the inorganic particles and water into the container, and disperse evenly at 5000rpm-10000rpm. Stir and add the cationic modifier at 100 rpm to 500 rpm, react at 30°C to 60°C for 1h to 10h, and prepare a cationic inorganic particle dispersion.

[0047] Preparation of ink receiving layer coating solution:

[0048] Add binder and curing agent into cationic inorganic particle dispersion liquid, stir evenly, and prepare ink receiving layer coating liquid with solid content of 3%-10%.

[0049] The coating method for coating the ink-receiving layer coating liquid on the support may be any known method, and may be a doctor blade coating method, an air knife coating method, a dip coating method, a spray coating method, or a gravure roll coating method. , slot coating method, rod coating method, slide extrusion coating method and the like.

[0050] Preparation of liquid electronic...

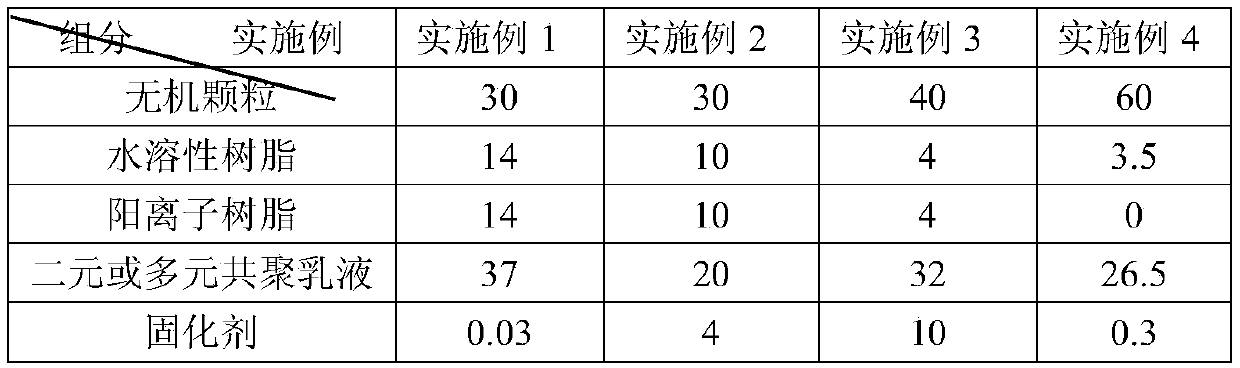

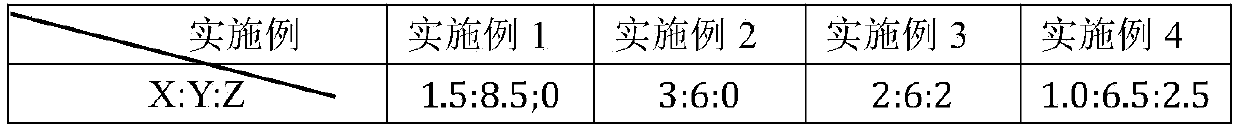

Embodiment 1

[0054] Preparation of Cationic Alumina Dispersion

[0055] Add 30g of alumina with a particle size of 0.5μm and 117ml of deionized water into the container, disperse for 1 hour under high-speed stirring at 8000rpm, and then add the cationic modifier diethylene Triamine 3g, continue stirring for 3h-5h to obtain cationic alumina dispersion. The zeta potential of the cationic alumina dispersion was +39.5mv.

[0056] Preparation of Ink Receiving Layer Coating Solution

[0057] Add 10% polyvinyl alcohol (polymerization degree 1700, hydrolysis degree 88%) 140g, 10% solid content cationic starch 140g, 50% solid content ethylene-vinyl acetate copolymer emulsion 74g (glass transition temperature) in cationic aluminum oxide dispersion liquid 60° C.), 0.03 g of curing agent boric acid, add deionized water until the overall solid content is 3%, stir evenly, let stand for defoaming, and obtain the ink receiving layer coating liquid.

[0058] Preparation of liquid electronic ink receptor...

Embodiment 2

[0061] Preparation of Cationic Barium Sulfate Dispersion

[0062] Add 30g of barium sulfate with a particle size of 1 micron and 117ml of deionized water into the container, disperse at 8000rpm with high-speed stirring for 1h, then add 3g of cationic modifier polyacrylamine at 40°C under stirring at 100rpm to 500rpm, Continue stirring for 3h to 5h to obtain a cationic barium sulfate dispersion. The ZETA potential was tested with a potentiometer from Shanghai Zhongchen Digital Technology Equipment Co., Ltd. to be +23.4mv.

[0063] Preparation of Ink Receiving Layer Coating Solution

[0064] Add 100g of 10% gelatin solution, 10g of polyethyleneimine, 80g of 25% solid content ethylene-acrylic acid copolymer emulsion (glass transition temperature 120 ℃), cross-linking agent formaldehyde 4g in cationic barium sulfate dispersion liquid, add deionized water to The overall solid content is 10%. Stir evenly, let stand to defoam, and obtain the ink receiving layer coating liquid.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com